Woodworker's Journal fall-2010, страница 11

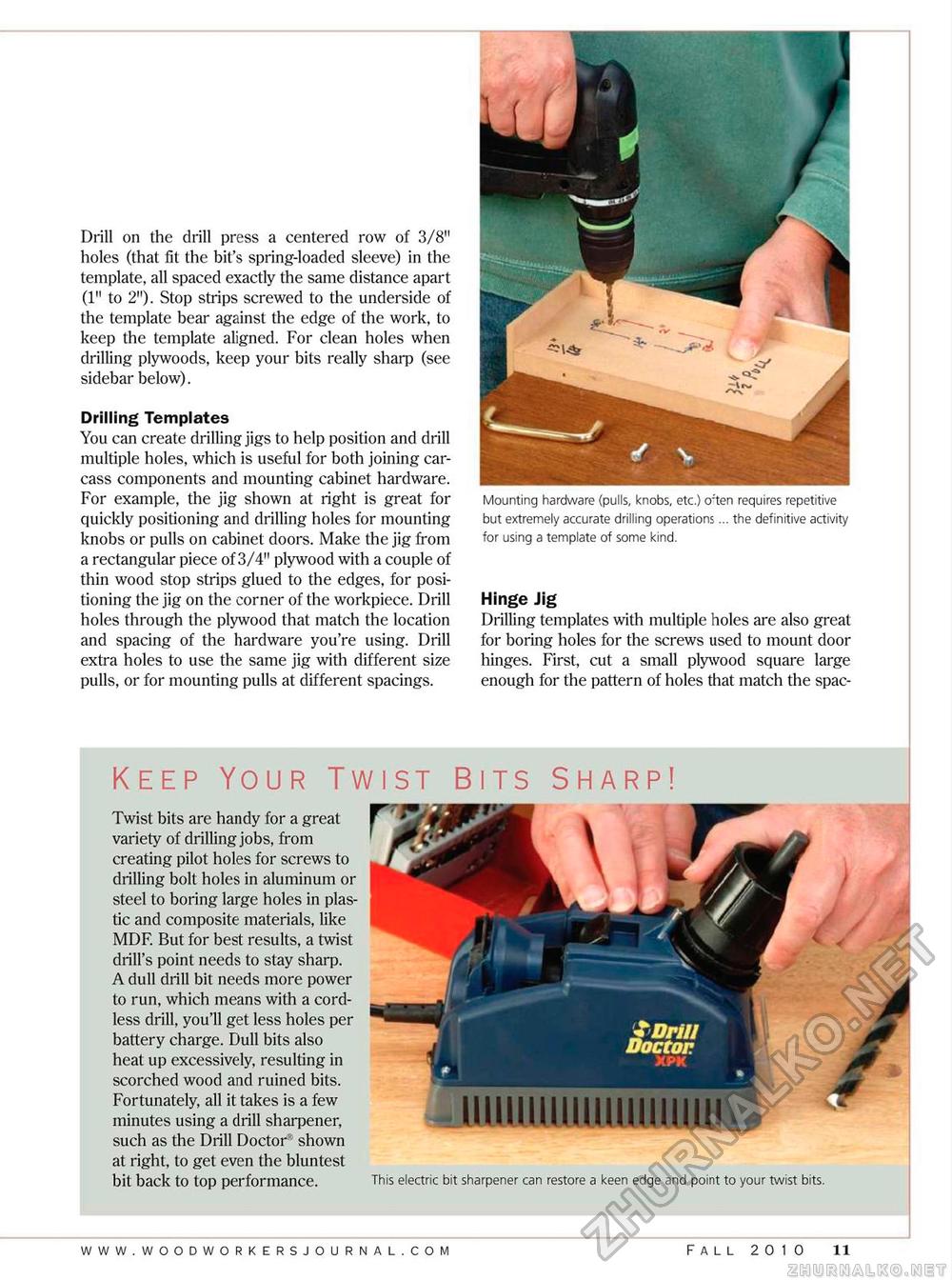

Drill on the drill press a centered row of 3/8" holes (that fit the bit's spring-loaded sleeve) in the template, all spaced exactly the same distance apart (1" to 2"). Stop strips screwed to the underside of the template bear against the edge of the work, to keep the template aligned. For clean holes when drilling plywoods, keep your bits really sharp (see sidebar below). Drilling Templates You can create drilling jigs to help position and drill multiple holes, which is useful for both joining carcass components and mounting cabinet hardware. For example, the jig shown at right is great for quickly positioning and drilling holes for mounting knobs or pulls on cabinet doors. Make the jig from a rectangular piece of 3/4" plywood with a couple of thin wood stop strips glued to the edges, for positioning the jig on the corner of the workpiece. Drill holes through the plywood that match the location and spacing of the hardware you're using. Drill extra holes to use the same jig with different size pulls, or for mounting pulls at different spacings. 1 Mounting hardware (pulls, knobs, etc.) o'ten requires repetitive but extremely accurate drilling operations... the definitive activity for using a template of some kind. Hinge Jig Drilling templates with multiple holes are also great for boring holes for the screws used to mount door hinges. First, cut a small plywood square large enough for the pattern of holes that match the spac- Twist bits are handy for a great variety of drilling jobs, from creating pilot holes for screws to drilling bolt holes in aluminum or steel to boring large holes in plastic and composite materials, like MDF. But for best results, a twist drill's point needs to stay sharp. A dull drill bit needs more power to run, which means with a cordless drill, you'll get less holes per battery charge. Dull bits also heat up excessively, resulting in scorched wood and ruined bits. Fortunately, all it takes is a few minutes using a drill sharpener, such as the Drill Doctor shown at right, to get even the bluntest bit back to top performance. This electric bit sharpener can restore a keen edge and point to your twist bits. Fall 2010 11 |