Woodworker's Journal fall-2010, страница 12

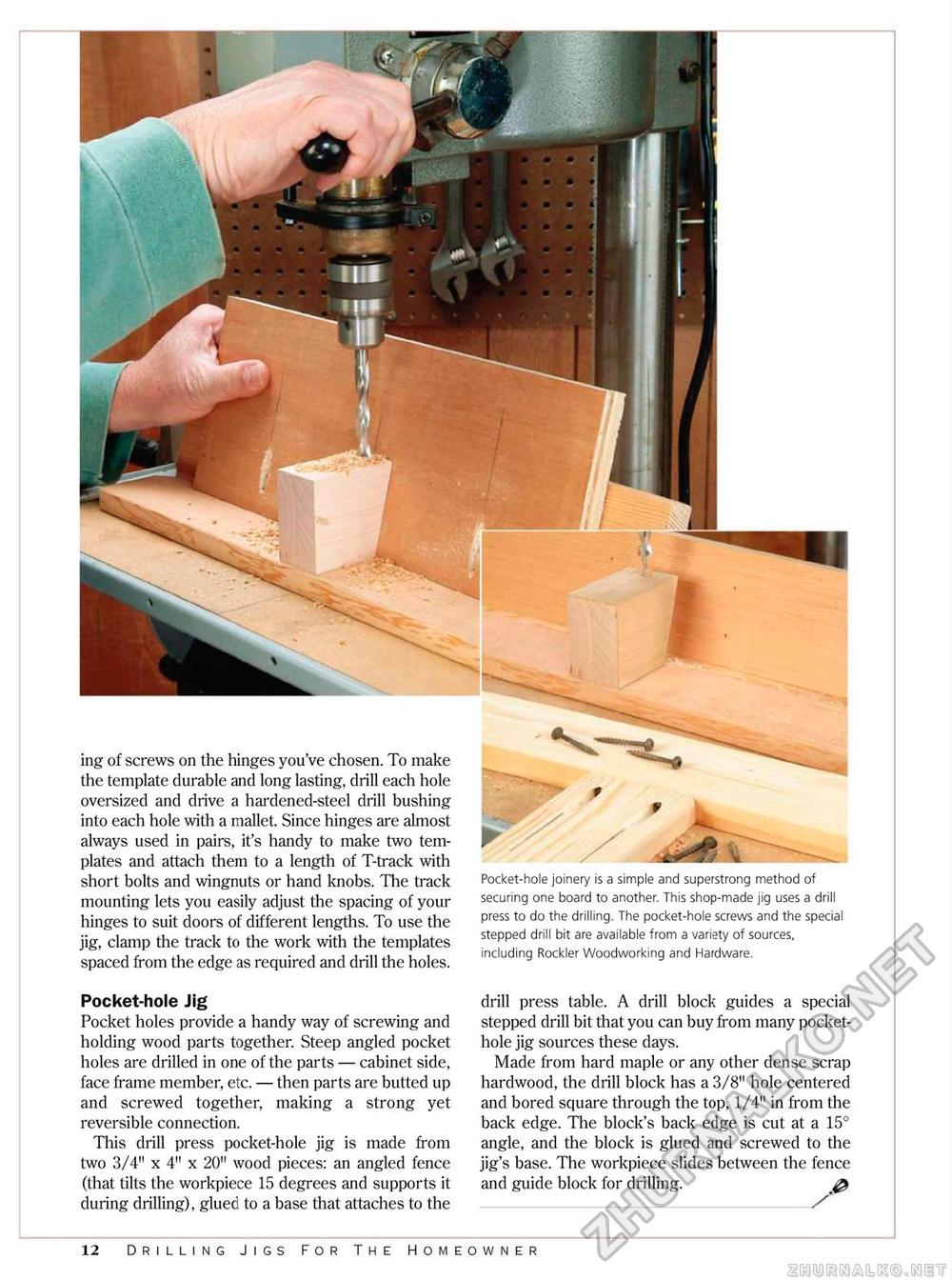

ing of screws on the hinges you've chosen. To make the template durable and long lasting, drill each hole oversized and drive a hardened-steel drill bushing into each hole with a mallet. Since hinges are almost always used in pairs, it's handy to make two templates and attach them to a length of T-track with short bolts and wingnuts or hand knobs. The track mounting lets you easily adjust the spacing of your hinges to suit doors of different lengths. To use the jig, clamp the track to the work with the templates spaced from the edge as required and drill the holes. Pocket-hole Jig Pocket holes provide a handy way of screwing and holding wood parts together. Steep angled pocket holes are drilled in one of the parts — cabinet side, face frame member, etc. — then parts are butted up and screwed together, making a strong yet reversible connection. This drill press pocket-hole jig is made from two 3/4" x 4" x 20" wood pieces: an angled fence (that tilts the workpiece 15 degrees and supports it during drilling), glued to a base that attaches to the W t Pocket-hole joinery is a simple and superstrong method of securing one board to another. This shop-made jig uses a drill press to do the drilling. The pocket-hole screws and the special stepped drill bit are available from a variety of sources, including Rockier Woodworking and Hardware. drill press table. A drill block guides a special stepped drill bit that you can buy from many pocket-hole jig sources these days. Made from hard maple or any other dense scrap hardwood, the drill block has a 3/8" hole centered and bored square through the top, 1/4" in from the back edge. The block's back edge is cut at a 15° angle, and the block is glued and screwed to the jig's base. The workpiece slides between the fence and guide block for drilling. ^ 12 Drilling Jigs For The Homeowner |