Woodworker's Journal Summer-2008, страница 82

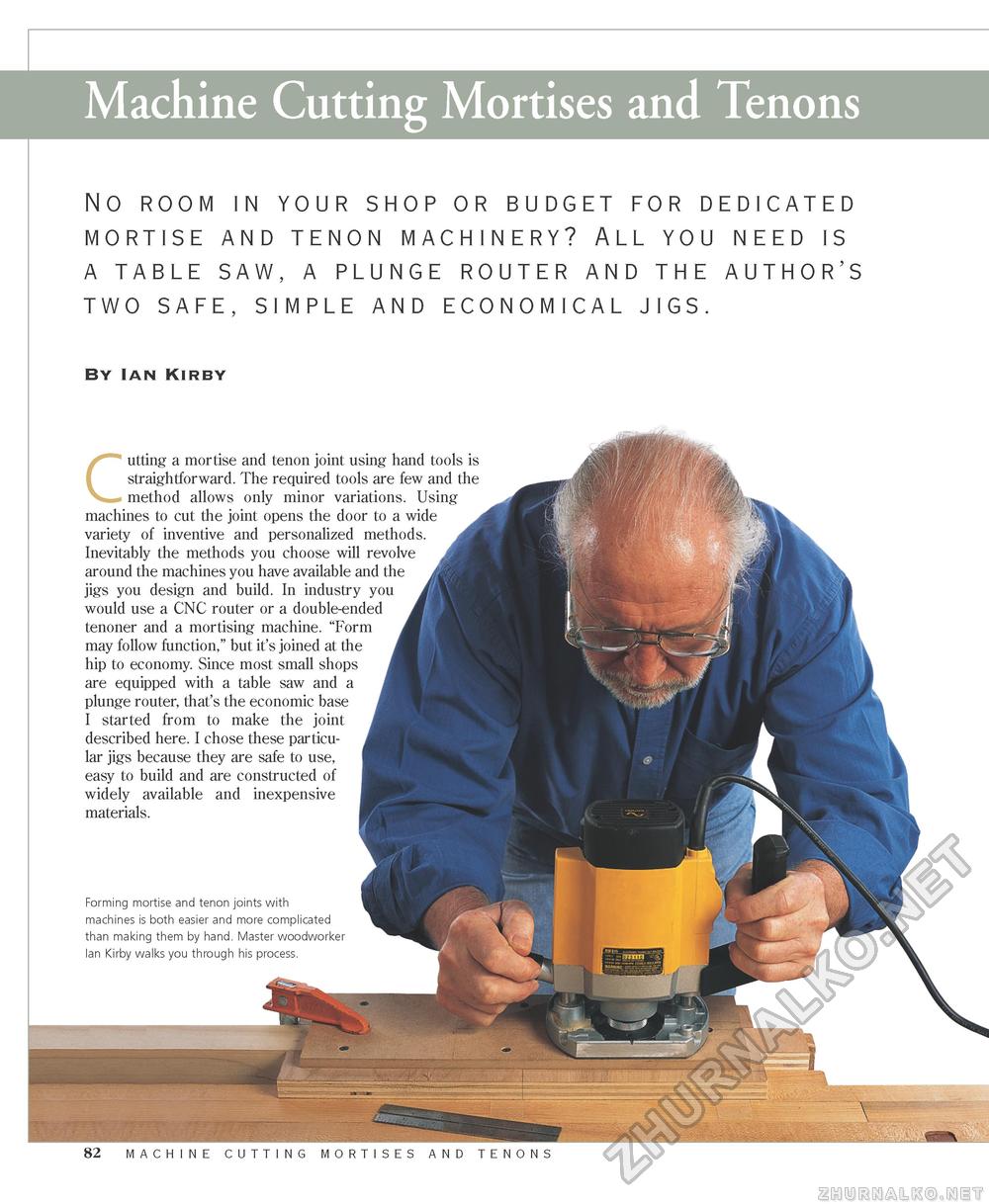

Machine Cutting Mortises and Tenons No room in your shop or budget for dedicated mortise and tenon machinery? All you need is a table saw, a plunge router and the author's two safe, simple and economical jigs. By Ian Kirby Forming mortise and tenon joints with machines is both easier and more complicated than making them by hand. Master woodworker Ian Kirby walks you through his process. Cutting a mortise and tenon joint using hand tools is straightforward. The required tools are few and the method allows only minor variations. Using machines to cut the joint opens the door to a wide variety of inventive and personalized methods Inevitably the methods you choose will revolve around the machines you have available and the jigs you design and build. In industry you would use a CNC router or a double-ended tenoner and a mortising machine. "Form may follow function," but it's joined at the hip to economy. Since most small shops are equipped with a table saw and a plunge router, that's the economic base I started from to make the joint described here. I chose these particular jigs because they are safe to use, easy to build and are constructed of widely available and inexpensive materials. 82 machine cutting mortises and tenons |