Woodworker's Journal Summer-2008, страница 83

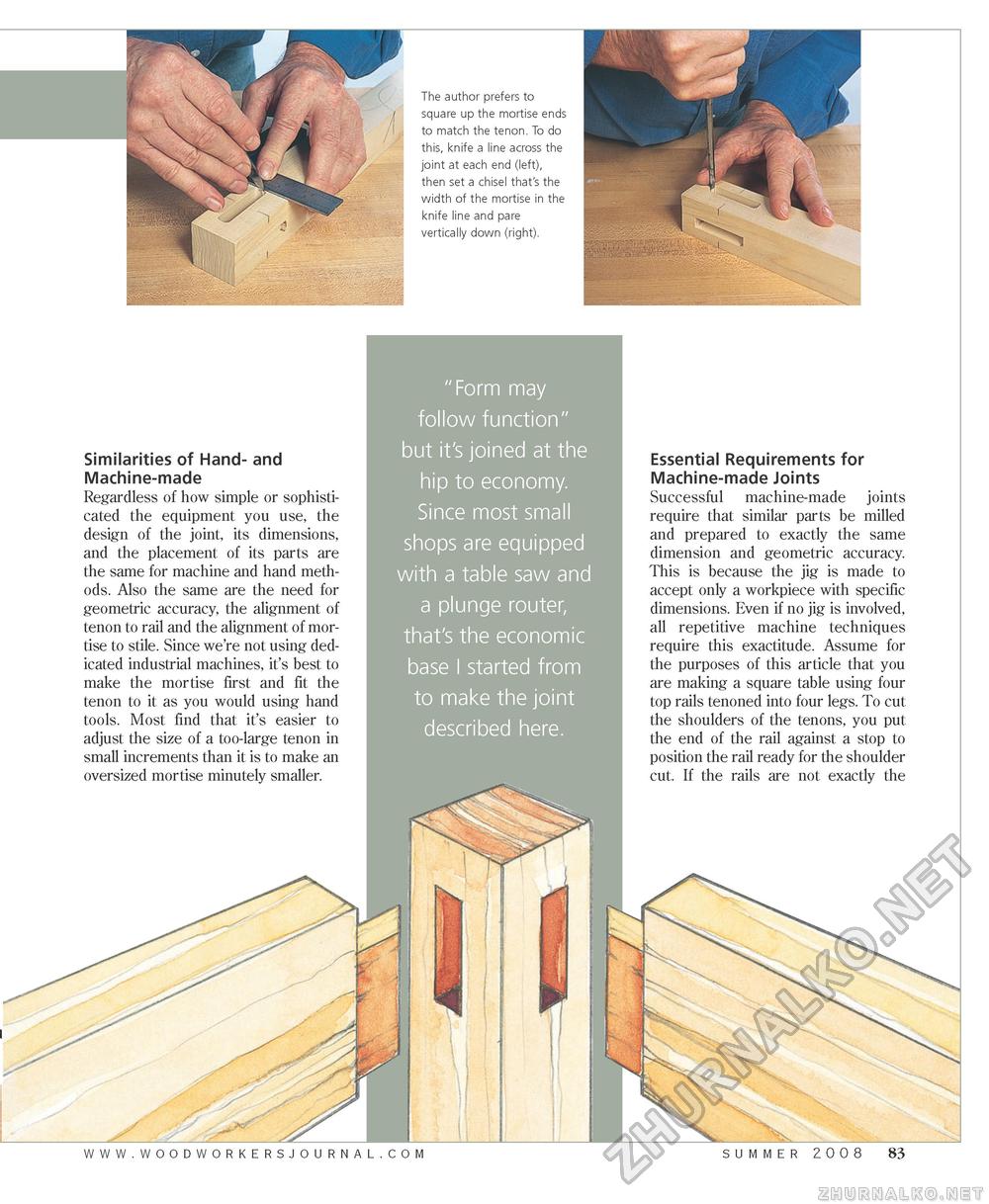

The author prefers to square up the mortise ends to match the tenon. To do this, knife a line across the joint at each end (left), then set a chisel that's the width of the mortise in the knife line and pare vertically down (right). Similarities of Hand- and Machine-made Regardless of how simple or sophisticated the equipment you use, the design of the joint, its dimensions, and the placement of its parts are the same for machine and hand methods. Also the same are the need for geometric accuracy, the alignment of tenon to rail and the alignment of mortise to stile. Since we're not using dedicated industrial machines, it's best to make the mortise first and fit the tenon to it as you would using hand tools. Most find that it's easier to adjust the size of a too-large tenon in small increments than it is to make an oversized mortise minutely smaller. "Form may follow function" but it's joined at the hip to economy. Since most small shops are equipped with a table saw and a plunge router, that's the economic base I started from to make the joint described here. Essential Requirements for Machine-made Joints Successful machine-made joints require that similar parts be milled and prepared to exactly the same dimension and geometric accuracy. This is because the jig is made to accept only a workpiece with specific dimensions. Even if no jig is involved, all repetitive machine techniques require this exactitude. Assume for the purposes of this article that you are making a square table using four top rails tenoned into four legs. To cut the shoulders of the tenons, you put the end of the rail against a stop to position the rail ready for the shoulder cut. If the rails are not exactly the www.woodworkersjourna l . c o m summer 2008 83 |