Woodworker's Journal winter-2010, страница 34

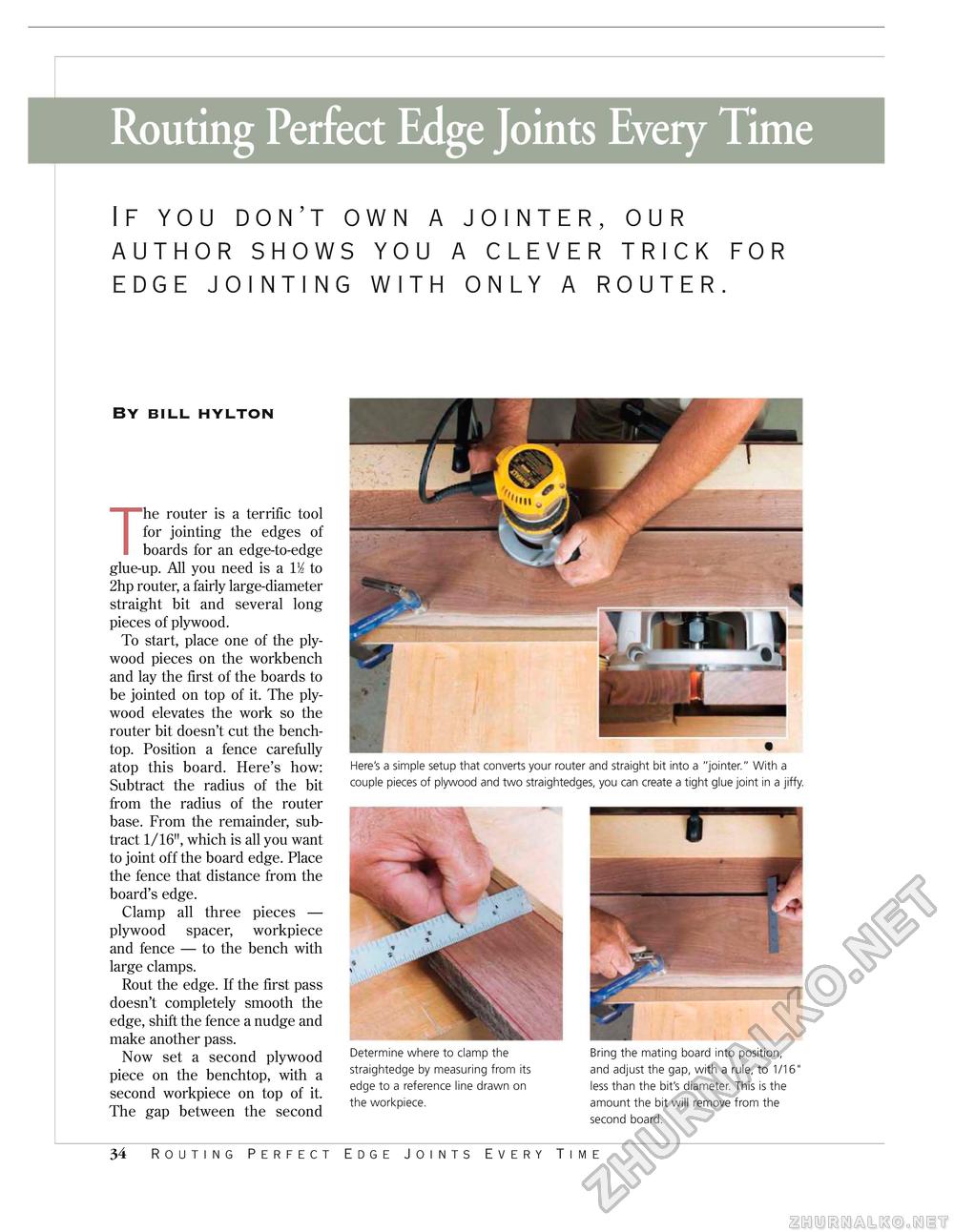

Routing Perfect Edge Joints Every Time if you don't own a author shows you edge jointing with jointer, our a clever trick for only a router. By bill hylton "he router is a terrific tool for jointing the edges of boards for an edge-to-edge glue-up. All you need is a Vk to 2hp router, a fairly large-diameter straight bit and several long pieces of plywood. To start, place one of the plywood pieces on the workbench and lay the first of the boards to be jointed on top of it. The plywood elevates the work so the router bit doesn't cut the bench-top. Position a fence carefully atop this board. Here's how: Subtract the radius of the bit from the radius of the router base. From the remainder, subtract 1/16", which is all you want to joint off the board edge. Place the fence that distance from the board's edge. Clamp all three pieces — plywood spacer, workpiece and fence — to the bench with large clamps. Rout the edge. If the first pass doesn't completely smooth the edge, shift the fence a nudge and make another pass. Now set a second plywood piece on the benchtop, with a second workpiece on top of it. The gap between the second Here's a simple setup that converts your router and straight bit into a "jointer." With a couple pieces of plywood and two straightedges, you can create a tight glue joint in a jiffy. Determine where to clamp the straightedge by measuring from its edge to a reference line drawn on the workpiece. Bring the mating board into position, and adjust the gap, with a rule, to 1/16" less than the bit's diameter. This is the amount the bit will remove from the second board. 34 ROUTING PERFECT EDGE JOINTS EVERY TIME |