Woodworker's Journal winter-2010, страница 49

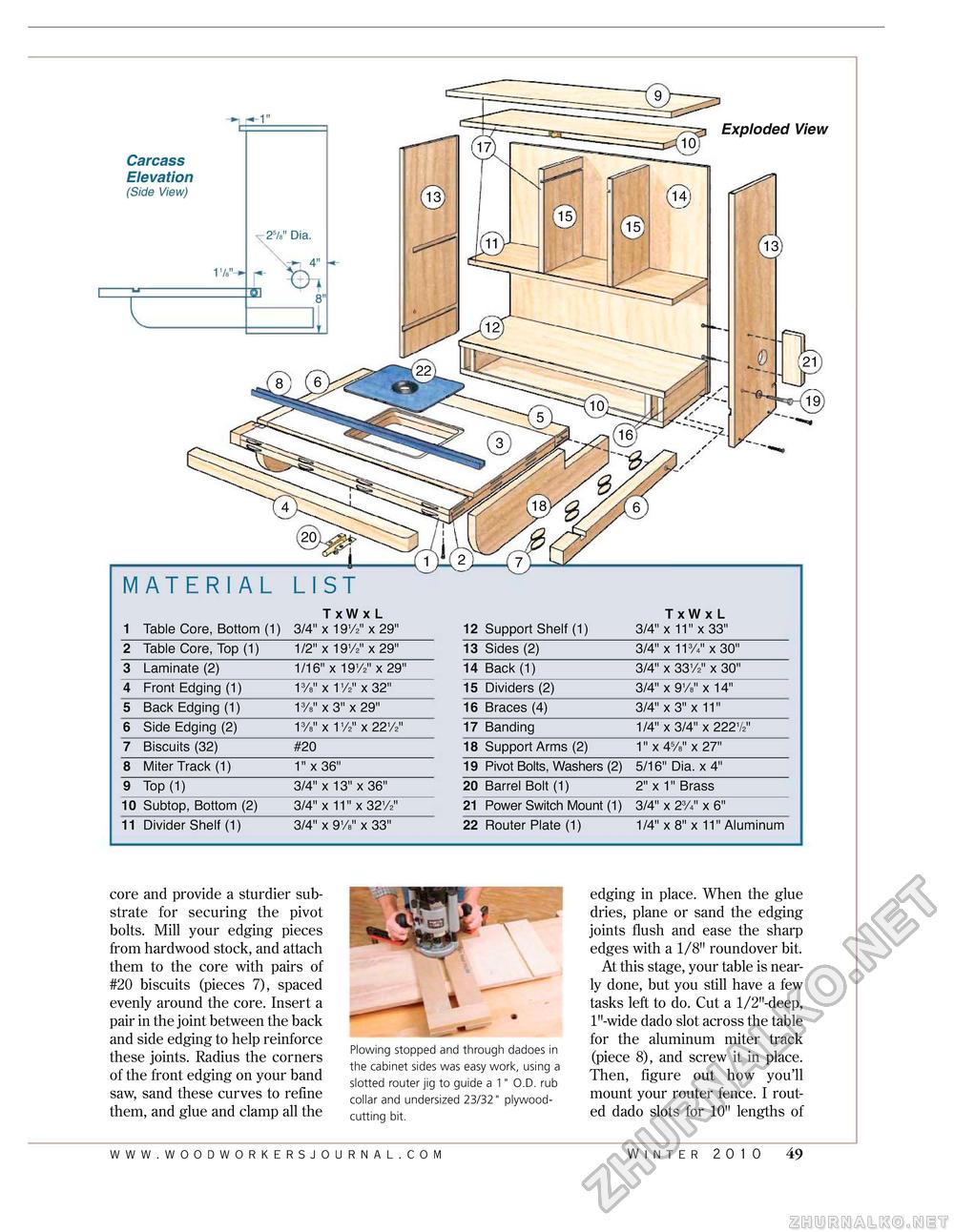

TxWxL TxWxL 1 Table Core, Bottom (1) 3/4" x 191/2" x 29" 12 Support Shelf (1) 3/4" x 11" x 33" TxWxL TxWxL 1 Table Core, Bottom (1) 3/4" x 191/2" x 29" 12 Support Shelf (1) 3/4" x 11" x 33"

core and provide a sturdier substrate for securing the pivot bolts. Mill your edging pieces from hardwood stock, and attach them to the core with pairs of #20 biscuits (pieces 7), spaced evenly around the core. Insert a pair in the joint between the back and side edging to help reinforce these joints. Radius the corners of the front edging on your band saw, sand these curves to refine them, and glue and clamp all the Plowing stopped and through dadoes in the cabinet sides was easy work, using a slotted router jig to guide a 1" O.D. rub collar and undersized 23/32" plywood-cutting bit. edging in place. When the glue dries, plane or sand the edging joints flush and ease the sharp edges with a 1/8" roundover bit. At this stage, your table is nearly done, but you still have a few tasks left to do. Cut a l/2M-deep, lM-wide dado slot across the table for the aluminum miter track (piece 8), and screw it in place. Then, figure out how you'll mount your router fence. I routed dado slots for 10" lengths of Carcass Elevation (Side View) 25/s" Dia. 0 21 Ur ^ ® Exploded View © © winter 2010 49 |

||||||||||||||||||||||||||||||||||||||||||||||||||