Creative Woodworks & crafts 2001-01, страница 46

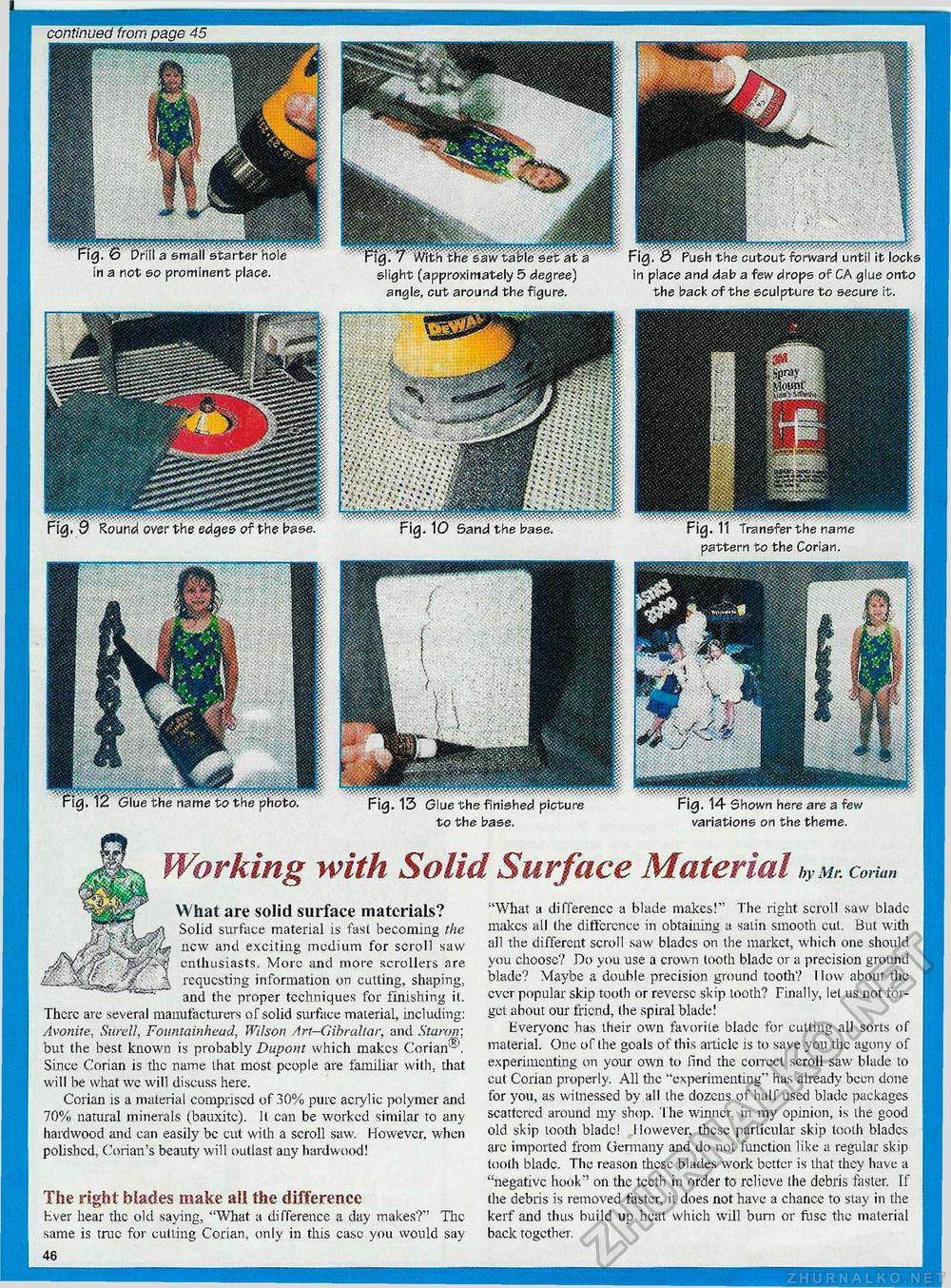

Fig, & Prill a small starter 'Hole in a not so prominent place. slight (approximately 5 degree) in place and dab a few drops of CA glue onto angle, cut around the figure. the back of the sculpture to secure it. Fig. 11 Transferthe name pattern to the Corian. Fig. 14 Shown here are a few variations on the theme. Fig. 13 Glue the finished picture to the base. Working with Solid Surface Material by Mr. Corian What are solid surface materials? Solid surface material is fast becoming the new and exciting medium for scroll saw enthusiasts. More and more scrollers are, requesting information on cutting, shaping, and the proper techniques for finishing i(. There are several manufacturers of solid surface maierial, including: Avonite. Swell, Fountainhead, Wilson Art-Gibraltar, and Staron; but the best known is probably Dupont which makes Corian®'. Since Corian is the name that most people are familiar with, that will be what we will discuss here. Corian is a material comprised of 30% pure acrylic polymer and 70% natural minerals (bauxite). 11 can be worked similar to any hardwood and can easily be cut with a scroll saw. However, when polished, Corian's beauty will outlast any hardwood! The right blades make ail the difference Ever hear the old saying, "What a difference a day makes?" The same is true for cutting C'orian, only in this case you would say 46 "What a difference a blade makes!" The right scroll saw blade makes all the difference in obtaining a satin smooth cut. But with all the different scroll saw blades on the market, which one should you choose? Do you use a crown tooth blade or a precision ground blade? Maybe a double precision ground tooth? I low about the ever popular skip tooth or reverse skip tooth? Finally, let us not forget about our friend, the spiral blade! Everyone has their own favorite blade for cutting all sorts of material. One of the goals of this article is to save you the agony of experimenting on your own to find the correct scroll saw blade to cut Corian properly. All the "experimenting" has already been done for you, as witnessed by all the dozens of half used blade packages scattered around my shop. T he winner, in my opinion, is the good old skip tooth blade! I lowever, these particular skip tooth blades are imported from Germany and do not function like a regular skip tooth blade. The reason these blades work better is that they have a "negative hook" on the teeth in order to relieve the debris taster. If the debris is removed faster, it does not have a chance to stay in the kerf and thus build up heat which will bum or fuse the material back together. |