Creative Woodworks & crafts 2001-01, страница 47

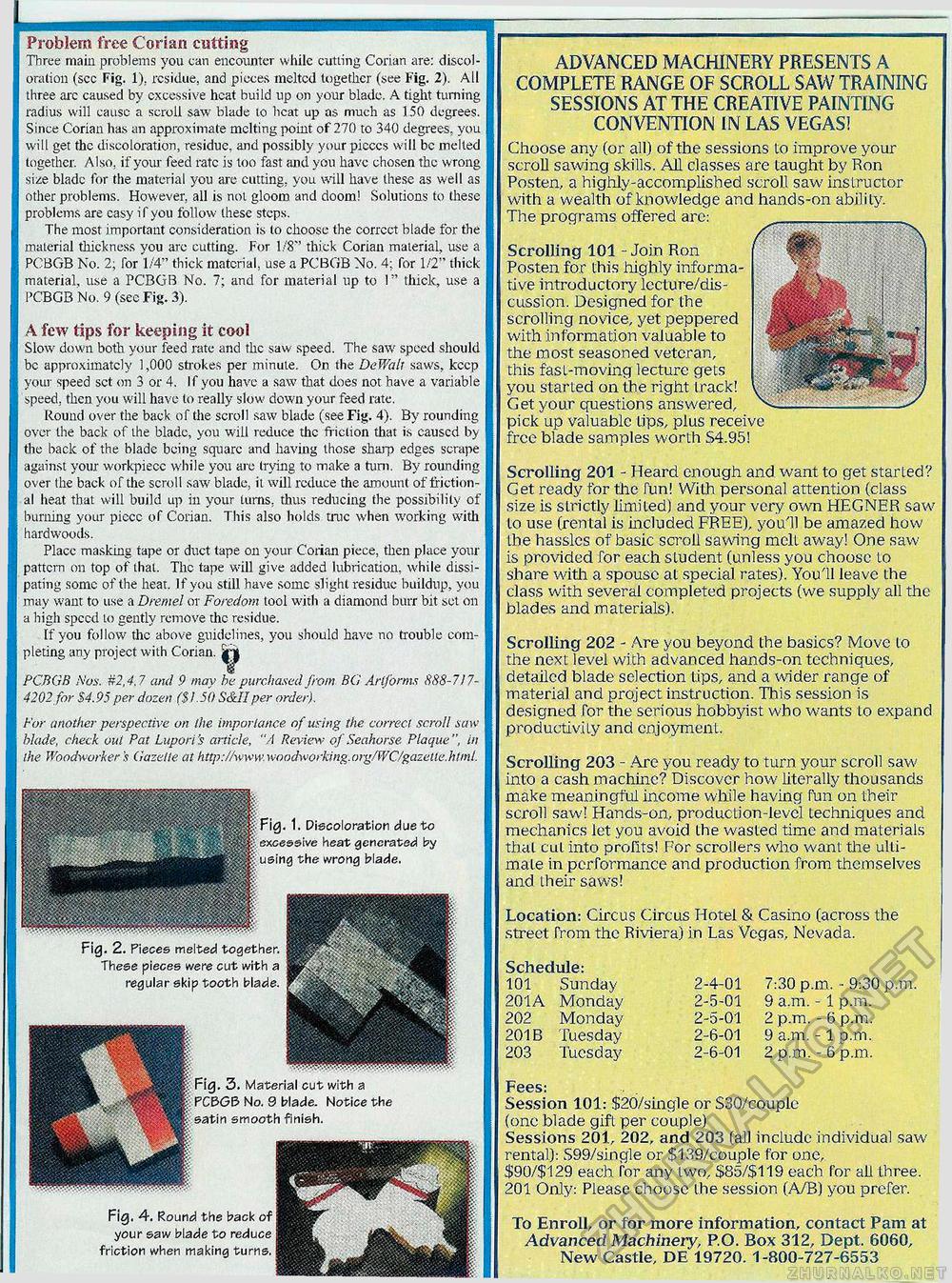

Problem free Corian cutting Three main problems you can encounter while cutting Corian are: discoloration (see Fig. 1), residue, and pieces melted together (see Fig. 2). All three arc caused by excessive heat build up on your blade. A tight turning radius will causc a scroll saw blade to heat up as much as 150 degrees. Since Corian has an approximate melting point of 270 to 340 degrees, you will get the discoloration, residue, and possibly your pieces will be melted together. Also, if your feed rate is too fast and you have chosen the wrong size blade for the material you are cutting, you will have these as well as other problems. However, all is not gloom and doom! Solutions to these problems are easy if you follow these steps. The most important consideration is to choose the correct blade for the material thickness you are cutting. For 1/8"' thick Corian material, use a PCBGB No. 2; for 1/4" thick material, use a PCBGB No. 4; for 1/2" thick material, use a PCBGB No. 7; and for material up to 1" thick, use a PCBGB No. 9 (sec Fig. 3). A few tips for keeping it cool Slow down both your feed rate and the saw speed. The saw speed should be approximately 1,000 strokes per minute. On the DeWalt saws, keep your speed set on 3 or 4. If you have a saw that does not have a variable speed, then you will have to really slow down your feed rate. Round over the back of the scroll saw blade (see Fig. 4). By rounding over the back of the blade, you will reduce the friction that is causcd by the back of the blade being square and having those sharp edges scrape against your workpiecc while you are trying to make a turn. By rounding over the back of the scroll saw1 blade, it will reduce the amount of friction-al heat that will build up in your turns, thus reducing the possibility of burning your piece of Corian. This also holds true when working with hardwoods. Place masking tape or duct tape on your Corian piece, then place your pattern on top of that. The tape will give added lubrication, while dissipating some of the heat. If you still have some slight residue buildup, you may want to use a Dremel or Foredom tool with a diamond burr bit set oil a high speed to gently remove the residue. If you follow the above guidelines, you should have no trouble completing any project with Corian. j|j|j PCBGB A'os. #2,4.7 and 9 may be purchased from BG Artforms 888-717-4202for $4.95 per dozen ($1.50 S&II per order). For another perspective on the imparlance of wring the correct scroll saw blade, check oui Pat Lupori's article, "A Review of Seahorse. Plaque", in lhe Woodworker s Gazelle, at http://wmv.woodyvorking.org/WC/gazetle.html. | Fig. 1. Piscoloration due to £ excessive heat generated by £ using the wrong blade. Fig. 2. Pieces melted together. These pieces were cut with a regular skip tooth blade. i Fig. 3. Material cut with a | PCBGB No. 9 blade. Notice the f satin smooth finish. Fig. 4. Round the back of your saw blade to reduce friction when making turns. ADVANCED MACHINERY PRESENTS A COMPLETE RANGE OF SCROLL SAW TRAINING SESSIONS AT THE CREATIVE PAINTING CONVENTION IN LAS VEGAS! Choose any (or all) of the sessions to improve your scroll sawing skills. AH classes are taught by Ron Posten, a highly-accomplished scroll saw instructor with a wealth of knowledge and hands-on ability. The programs offered are: _______ Scrolling 101 - Join Ron Posten for this highly informative introductory lecture/dis-cussion. Designed for the scrolling novice, yet peppered with information valuable to the most seasoned veteran, this fast-moving lecture gets you started on the right track! Get your questions answered, N pick up valuable Lips, plus receive free blade samples worth S4.951 Scrolling 201 - Heard enough and want to get started? Get ready for the fun! With personal attention (class size is strictly limited) and your very own HEGNER saw to use (rental is included FREE), you'll be amazed how the hassles of basic scroll sawing melt away! One saw is provided for each student (unless you choose to share with a spouse at special rates). You'll leave the class with several completed projects (we supply all the blades and materials). Scrolling 202 - Are you beyond the basics? Move to the next level with advanced hands-on techniques, detailed blade selection tips, and a wider range of material and project instruction. This session is designed for the serious hobbyist who wants lo expand productivity and enjoyment. Scrolling 203 - Are you ready to turn your scroll saw into a cash machine? Discover how literally thousands make meaningful income while having fun on their scroll saw! Hands-on, production-level techniques and mechanics let you avoid the wasted time and materials that cut into profits! For scrollers who want the ultimate in performance and production from themselves and their saws! Location: Circus Circus Hotel & Casino (across the street from the Riviera) in Las Vegas, Nevada. Schedule: 101 Sunday 2-4-01 201A Monday 2-5-01 202 Monday 2-5-01 201B Tuesday 2-6-01 203 Tuesday 2-6-01 7:30 p.m. - 9:30 p.m. 9 a.m. - 1 p.m. 2 p.m. - 6 p.m. 9 a.m. -1 p.m. 2 p.m. - 6 p.m. Fees: Session 101: $2C)/single or S30/couple (one blade gift per couple) Sessions 201, 202, and 203 (all include individual saw rental): S99/single or $139/couple for one, $90/$ 129 each Tor any two, $85/5119 each for all three. 201 Only: Please choose the session (A/B) you prefer. To Enroll, or for more information, contact Pam at Advanced Machinery, P.O. Box 312, Dept. 6060, New Castle, DE 19720. 1-800-727-6553 |