Creative Woodworks & crafts 2001-03, страница 41

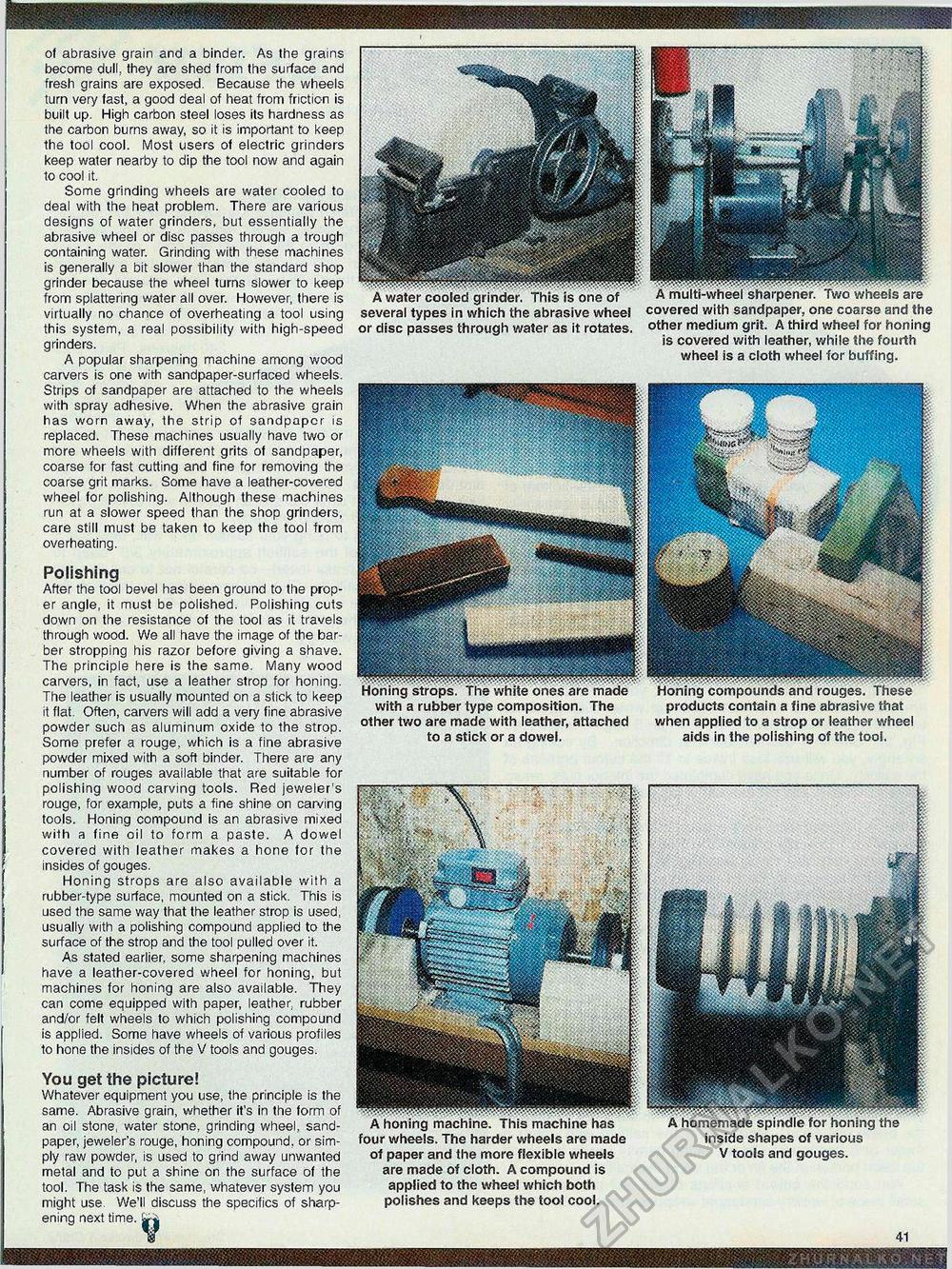

Mi of abrasive grain and a binder. As the grains become dull, they are shed from the surface and fresh grains are exposed. Because the wheels turn very fast, a good deal of heat from friction is built up. High carbon steel loses its hardness as the carbon burns away, so it is important to keep the tool cool. Most users of electric grinders keep water nearby to dip the tool now and again to cool it. Some grinding wheels are water cooled to deal with the heat problem. There are various designs of water grinders, but essentially the abrasive wheel or disc passes through a trough containing water. Grinding with these machines is generally a bit slower than the standard shop grinder because the wheel turns slower to keep from splattering water all over. However, there is virtually no chance of overheating a tool using this system, a real possibility with high-speed grinders. A popular sharpening machine among wood carvers is one with sandpaper-surfaced wheels. Strips of sandpaper are attached to the wheels with spray adhesive. When the abrasive grain has worn away, the strip of sandpaper is replaced. These machines usually have two or more wheels with different grits of sandpaper, coarse for fast cutting and fine for removing the coarse grit marks. Some have a leather-covered wheel for polishing. Although these machines run at a slower speed than the shop grinders, care still must be taken to keep the tool from overheating. Polishing After the tool bevel has been ground to the proper angle, it must be polished. Polishing cuts down on the resistance of the tool as it travels through wood. We all have the image of the barber stropping his razor before giving a shave. The principle here is the same. Many wood carvers, in fact, use a leather strop for honing. The leather is usually mounted on a stick to keep it flat. Often, carvers will add a very fine abrasive powder such as aluminum oxide to the strop. Some prefer a rouge, which is a fine abrasive powder mixed with a soft binder. There are any number of rouges available that are suitable for polishing wood carving tools. Red jeweler's rouge, for example, puts a fine shine on carving tools. Honing compound is an abrasive mixed with a fine oil to form a paste. A dowel covered with leather makes a hone for the insides of gouges. Honing strops are also available with a rubber-type surface, mounted on a stick. This is used the same way that the leather strop is used, usually with a polishing compound applied to the surface of the strop and the tool pulled over it. As stated earlier, some sharpening machines have a leather-covered wheel for honing, but machines for honing are also available. They can come equipped with paper, leather rubber and/or felt wheels to which polishing compound is applied. Some have wheels of various profiles to hone the insides of the V tools and gouges. You get the picture! Whatever equipment you use, the principle is the same. Abrasive grain, whether it's in the form of an oil stone, water stone, grinding wheel, sandpaper, jeweler's rouge, honing compound, or simply raw powder, is used to grind away unwanted metal and to put a shine on the surface of the tool. The task is the same, whatever system you might use. We'll discuss the specifics of sharpening next time, j inside shapes of various V tools and gouges. A honing machine. This machine has four wheels. The harder wheels are made of paper and the more flexible wheels are made of cloth. A compound is applied to the wheel which both polishes and keeps the tool cool. A water cooled grinder. This is one of several types in which the abrasive wheel or disc passes through water as it rotates. Honing strops. The white ones are made with a rubber type composition. The other two are made with leather, attached to a stick or a dowel. Honing compounds and rouges. These products contain a fine abrasive that when applied to a strop or feather wheel aids in the polishing of the tool. A multi-wheel sharpener. Two wheels are covered with sandpaper, one coarse and the other medium grit. A third wheel for honing is covered with leather, while the fourth wheel is a cloth wheel for buffing. |