Creative Woodworks & crafts 2003-04, страница 56

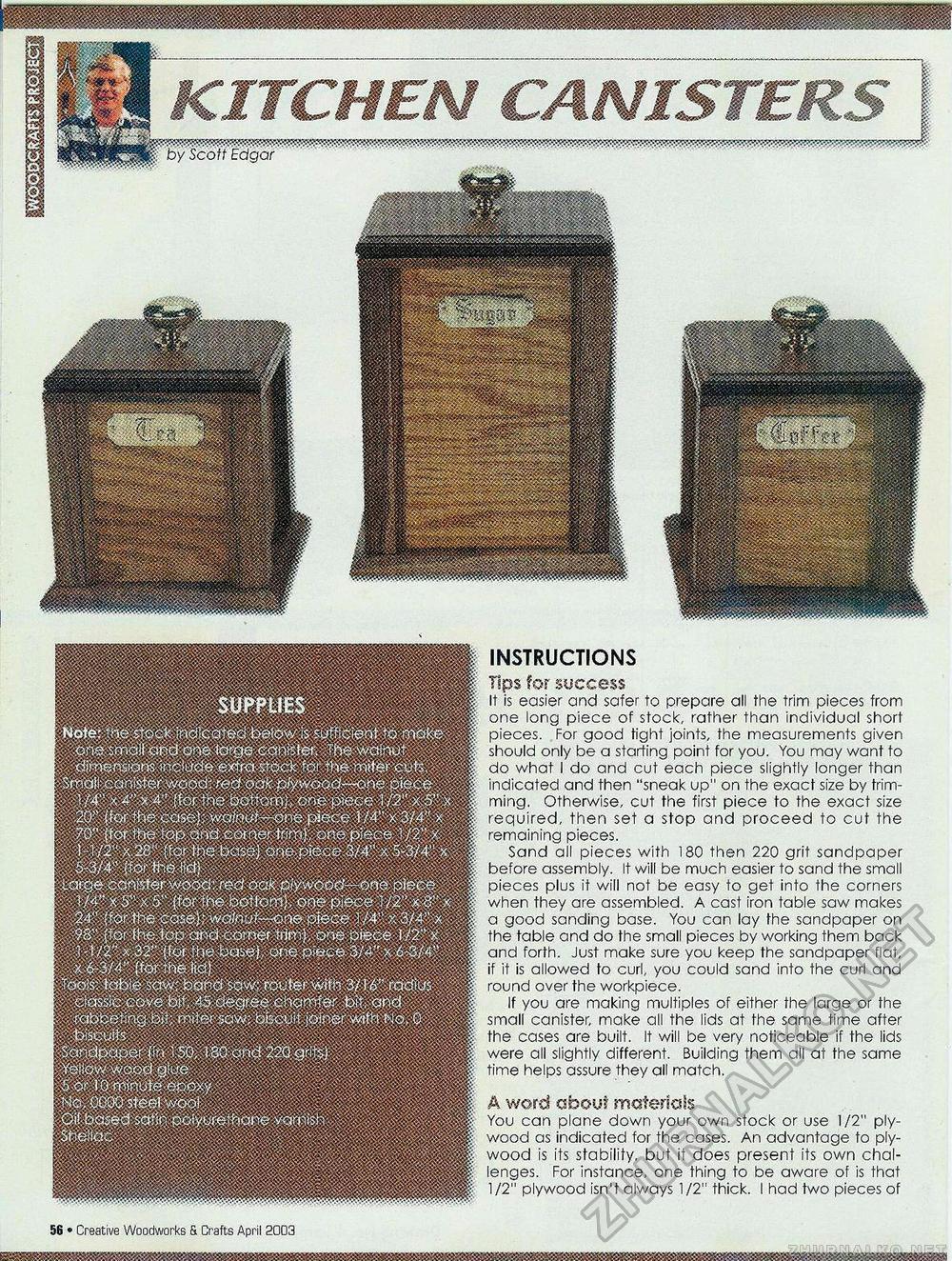

INSTRUCTIONS Tips for success It is easier and safer to prepare all the trim pieces from one long piece of stock, rather than individual short pieces. For good tight joints, the measurements given should only be a starting point for you. You may want to do what I do and cut each piece slightly longer than indicated and then "sneak up" on the exact size by trimming. Otherwise, cut the first piece to the exact size required, then set a stop and proceed to cut the remaining pieces. Sand all pieces with 180 then 220 grit sandpaper before assembly. It will be much easier to sand the small pieces plus it will not be easy to get into the corners when they are assembled. A cast iron table saw makes a good sanding base. You can lay the sandpaper on the table and do the small pieces by working them back and forth. Just make sure you keep the sandpaper flat, if it is allowed to curl, you could sand into the curl and round over the workpiece. If you are making multiples of either the large or the small canister, make all the lids at the same time after the cases are built. It will be very noticeable if the lids were all slightly different. Building them all at the same time helps assure they all match. A word about materials You can plane down your own stock or use 1/2" plywood as indicated for the cases. An advantage fo plywood is its stability, but it does present its own challenges. For instance, one thing to be aware of is that 1/2" plywood isn't always 1/2" thick. I had two pieces of Creative Woodworks S. Crafts April 2003 • 19 |