Creative Woodworks & crafts 2004-06, страница 43

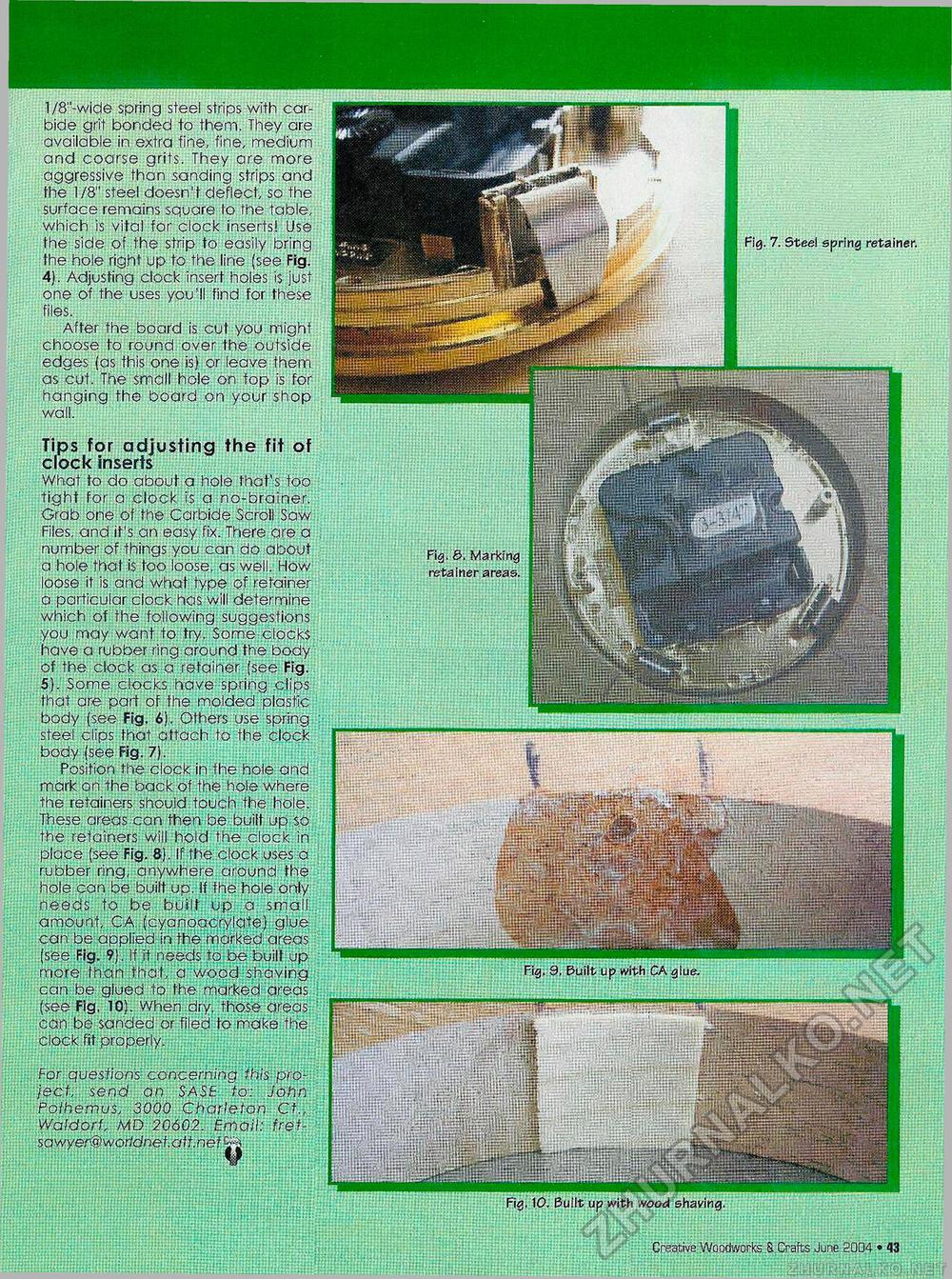

1 /8"-wicie spring steel strips with carbide grit bonded to them. They are available in extra fine, fine, medium and coarse grits. They are more aggressive than sanding strips and the 1/8" steel doesn't deflect, so the surface remains square fo the table, which is vital far clock inserts! Use the side of the strip to easily bring the hole right up to the line (see Fig. 4). Adjusting clock insert holes is just one of the uses you'll find for these files. After the board is cut you might choose to round over the outside edges (as this one is) or leave them as cut. The small hole on top is for hanging the board on your shop wall. Fig. 7. Steel spring retainer. Tips for adjusting the fit of clock inserts What to do about a hole that':s too tight for a clock is a no-brainer. Grab one of the Carbide Scroll Saw Files, and it's an easy fix. There are a number of things you can do about a hole thai is too loose, as well. How loose it is and what type of retainer a particular clock has will determine which of the following suggestions you may want to. try. Some clocks have a rubber ring around the body of the clock as a retainer [see Fig. 5). Some clocks have spring clips that are part of the molded plastic body (see Fig. &). Others use spring steel clips that attach to the clock body (see Fig. 7). Position the clock in the hole and mark on the back of the hole where the retainers should touch the hole. These areas can then be built up so the retainers will hold the clock, in place (see Fig. 8). If the clock uses a rubber ring, anywhere around the hole con be built up. If the hole only needs to be built up a small amount, CA (cyanoacrylote) glue can be applied in the marked areas (see Fig. 9). If it needs to be built up more than that, a wood shaving can be glued to the marked areas (see Fig. 10). When dry, those areas can be sanded or filed to make the clock fit properly. Fig. &. Marking retainer areas. For questions concerning this project, send an SASE to: John Polhemus, 3000 Charleton Cf., Waldorf, MD 20602. Email: fret-sawyenWworldnef.aft.nef ^ Fig, 10. Built up with wood shaving. Creative Woodworks a.Crafts June 20Q4 • 13 |