Creative Woodworks & crafts 2004-06, страница 45

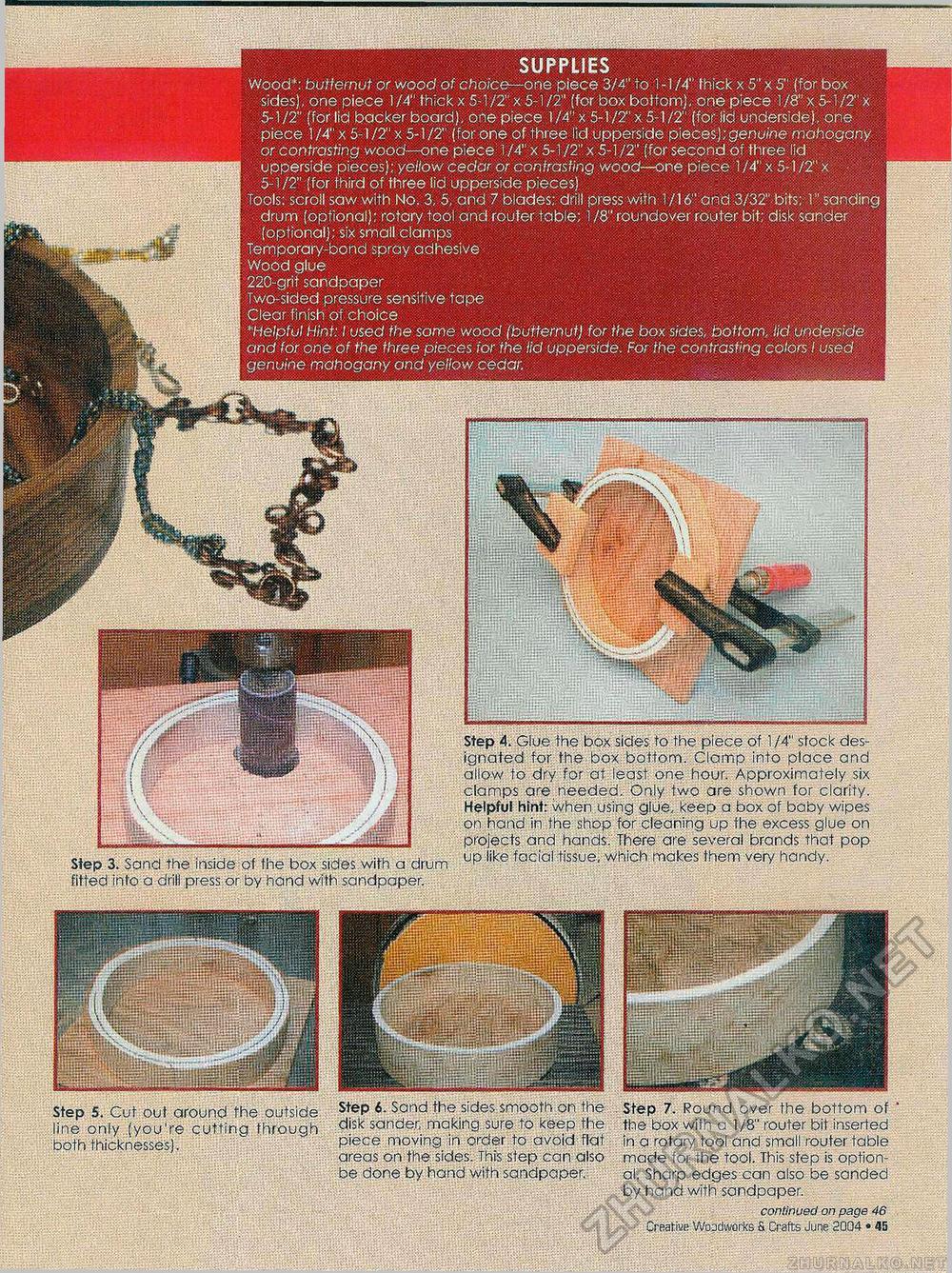

SUPPLIES Wood*: butternut or wood of choice—one piece 3/4" to 1-1/4" thick x 5" x 5" (for box sides), One piece 1/4" thick x 5-1/2" x 5-1/2" (for box bottom), one piece 1/8" x 5-1/2" x 5-1/2" (for lid backer board), one piece 1/4" x 5-1/2" x 5-1/2' (for iid underside), one piece 1/4" x 5-l/2"x 5-1/2" (for one of three iid upperside pieces)-genuine mahogany, or contrasting wood—-one piece 1 /4" x 5-1/2" x 5-1/2" (for second of three lid upperside pieces); yellow cedar or contrasting wood—one piece l/4"x5-l/2"x 5-1/2" (for third of three lid upperside pieces) Tools: scroll saw with No. 3, 5 and 7 blades;, drill press with: 1 /16" and .3/32" bits; 1" sanding drum (optional); rotary tool and router table; 1 /8" rourtdover router bit; disk sander (optional); six small clamps Temporary-bond spray adhesive Wood glue 220-grit sandpaper Two-sided pressure sensitive tape Clear finish of choice *Helpful Hint: I used the same wood (butternut) for the box sides, bottom, lid underside and for one of the three pieces tor the lid upperside. For the contrasting colors I used genuine mahogany and yellow cedar. Step 4. Glue the box sides to the piece of 1 /4" stock designated for the box bottom. Clamp into place and allow to dry for at least one hour. Approximately six clamps are needed. Only two are shown for clarity. Helpful hint: when using glue, keep a box of baby wipes on hand in the shop for cleaning up the excess glue on projects and hands: There are several brands that pop up like facial tissOe, which makes them very handy. Step 3. Sand the inside of the box sides with a drum fitted into a drill press or by hand with sandpaper. Sil§SlSS!sj Step 6. Sand the sides smooth on the . Step 7. Round over the bottom of disk sander, making sure to keep the the box with a 1/8" router bit inserted piece moving in order to avoid flat in a rotary tool and small router table areas on the sides. This step can also made for the tool. This step is option-be done by hand with sandpaper. ai. Sharp edges can also be sanded by hand with sandpaper. continued on page 46 Creative Woodworks & Crafts June 2004 • 45 Step 5. Cut out around the outside line only (you're cutting through both thicknesses). |