Popular Woodworking 2000-10 № 117, страница 24

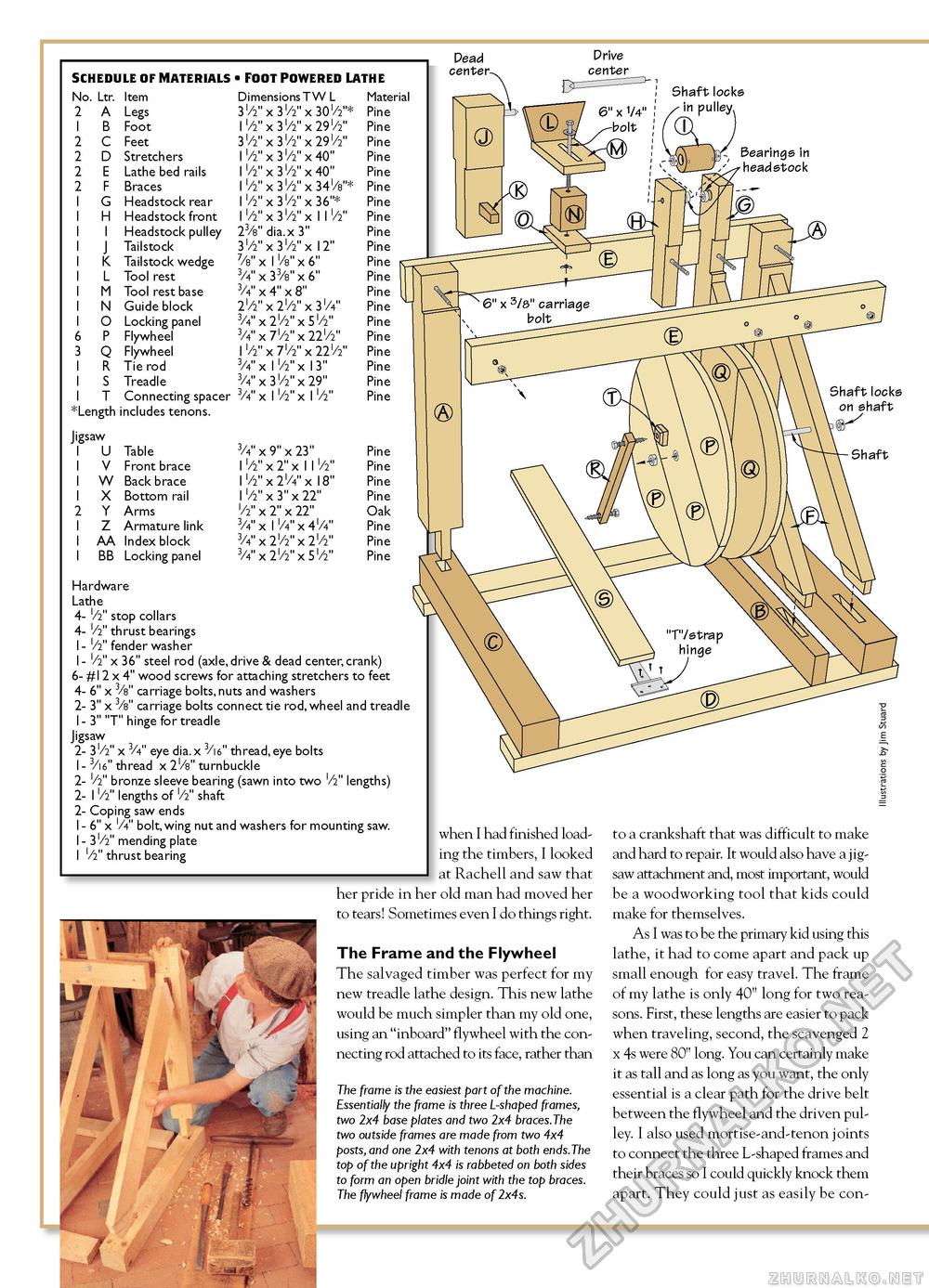

SCHEDULE OF MATERiALS • FOOT POWERED LATHE No. Ltr. Item Legs Foot Feet Stretchers Lathe bed rails Braces Headstock rear Headstock front Headstock pulley Tailstock Tailstock wedge Tool rest Tool rest base Guide block Locking panel Flywheel Flywheel Tie rod Treadle Connecting spacer includes tenons. Dimensions T W L 3'/2" x 3'/2" x 30'/2"* I '/2" x 3I/2" x 29I/2" 3I/2" x 3i/2" x 29i/2" 11'/2" x 3I/2" x 40" 11/2" x 3I/2" x 40" 11'/2" x 3 l^" x 34i/8"* I I/2" x 3I/2" x 36"* I I/2" x 3I/2" x II ^ 23/8" dia.x 3" 3I/2" x 3i/2" x I2" 7/8" x I ^ x 6" W' x 33/8" x 6" V4" x 4" x 8" 2^2" x 2i/2" x 3i/4" W x 2I/2" x S^" x 7I/2" x 22I/2" I ^ x 7I/2" x 221/2" W' x I ^ x I3" W x 3I/2" x 29" W' x I ^ x I I/2" Material Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine Pine 2C 2 D 2 E 2F G H I J K L M N O 6P 3 Q I R IS IT *Length Jigsaw I I I 1 2 I I I Hardware Lathe 4- I/2" stop collars 4- I/2" thrust bearings I - I/2" fender washer I - I/2" x 36" steel rod (axle, drive & dead center, crank) 6- #I2 x 4" wood screws for attaching stretchers to feet 4- 6" x 3/8" carriage bolts,nuts and washers 2- 3" x 3/8" carriage bolts connect tie rod, wheel and treadle I - 3" "T" hinge for treadle Jigsaw 2- 3i/2" x 3/4" eye dia.x 3/i6" thread,eye bolts 1- 3/i6" thread x 2I/a" turnbuckle 2- I/2" bronze sleeve bearing (sawn into two I/2" lengths) 2- 11/2" lengths of ^ shaft 2- Coping saw ends I - 6" x bolt, wing nut and washers for mounting saw. I- 3I/2" mending plate I I/2" thrust bearing

Shaft locks in pulley. Bearings in headstock when I had finished loading the timbers, I looked at Rachell and saw that her pride in her old man had moved her to tears! Sometimes even I do things right. The Frame and the Flywheel The salvaged timber was perfect for my new treadle lathe design. This new lathe would be much simpler than my old one, using an "inboard" flywheel with the connecting rod attached to its face, rather than The frame is the easiest part of the machine. Essentially the frame is three L-shaped frames, two 2x4 base plates and two 2x4 braces.The two outside frames are made from two 4x4 posts, and one 2x4 with tenons at both ends.The top of the upright 4x4 is rabbeted on both sides to form an open bridle joint with the top braces. The flywheel frame is made of 2x4s. to a crankshaft that was difficult to make and hard to repair. It would also have a jigsaw attachment and, most important, would be a woodworking tool that kids could make for themselves. As I was to be the primary kid using this lathe, it had to come apart and pack up small enough for easy travel. The frame of my lathe is only 40" long for two reasons. First, these lengths are easier to pack when traveling, second, the scavenged 2 x 4s were 80" long. You can certainly make it as tall and as long as you want, the only essential is a clear path for the drive belt between the flywheel and the driven pulley. I also used mortise-and-tenon joints to connect the three L-shaped frames and their braces so I could quickly knock them apart. They could just as easily be con- |