Popular Woodworking 2000-10 № 117, страница 25

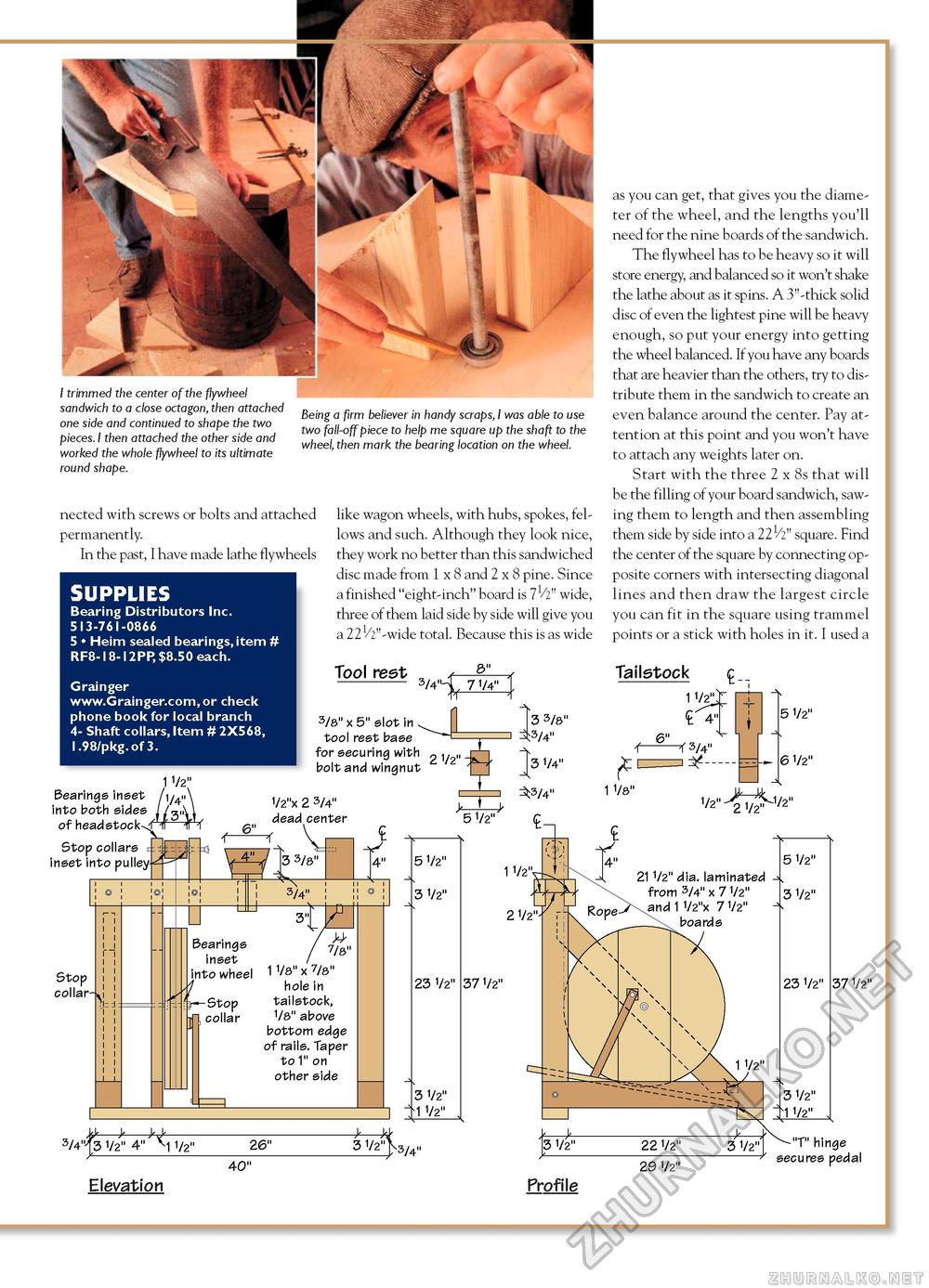

I trimmed the center of the flywheel sandwich to a close octagon, then attached one side and continued to shape the two pieces. I then attached the other side and worked the whole flywheel to its ultimate round shape. Being a firm believer in handy scraps, I was able to use two fall-off piece to help me square up the shaft to the wheel, then mark the bearing location on the wheel. nected with screws or bolts and attached permanently. In the past, I have made lathe flywheels SUPPLIES Bearing Distributors Inc. 513-761-0866 5 • Heim sealed bearings, item # RF8-18-12PP, $8.50 each. Grainger www.Grainger.com,or check phone book for local branch 4- Shaft collars, Item # 2X568, 1.98/pkg. of 3. like wagon wheels, with hubs, spokes, fellows and such. Although they look nice, they work no better than this sandwiched disc made from 1 x 8 and 2 x 8 pine. Since a finished "eight-inch" board is 7V2" wide, three of them laid side by side will give you a 22V2" -wide total. Because this is as wide Tool rest 8" 3/8" x 5" slot tool rest base 1 1/2" Bearings inset /1/4'A into both sides j/3"\ 1 of headstock^T^-fV for securing with 2 i/2" bolt and wingnut 3 3/8" ] :^3/4" 3 1/4" 1/2"x 2 3/4" dead center Stop collars inset into pulley Stop collar- 4" A. 3 3/8" 3/4" C 4" 5 1/2" I 3/4" C^ as you can get, that gives you the diameter of the wheel, and the lengths you'll need for the nine boards of the sandwich. The flywheel has to be heavy so it will store energy, and balanced so it won't shake the lathe about as it spins. A 3"-thick solid disc of even the lightest pine will be heavy enough, so put your energy into getting the wheel balanced. If you have any boards that are heavier than the others, try to distribute them in the sandwich to create an even balance around the center. Pay attention at this point and you won't have to attach any weights later on. Start with the three 2 x 8s that will be the filling of your board sandwich, sawing them to length and then assembling them side by side into a 221/2" square. Find the center of the square by connecting opposite corners with intersecting diagonal lines and then draw the largest circle you can fit in the square using trammel points or a stick with holes in it. I used a Tailstock 1 1/2" C 4" 6" f-<3/4" L-,

1 1/8" 5 1/2" 6 1/2" IL_U, Bearings inset into wheel t Stop collar I 7/8" 1 1/8" x 7/8" hole in tailstock, 1/8" above bottom edge of rails. Taper to 1" on other side 3/4

3 1/2" ■1 1/2" 40" 5 1/2" 3 1/2" 23 1/2" 3 1/2" ■1 1/2" 1 1/2". 2 1/2" 21 1/2" dia. laminated from 3/4" x 7 1/2" and 1 1/2"x 7 1/2" boards 37 1/2" 5 1/2" 3 1/2" 23 1/2" 1 1/2" 3 1/2" 1 1/2" 37 1/2" 40" 3 1/2" 22 1/2" 29 1/2" 3 1/2" "T" hinge secures pedal Elevation Profile |

||||||||||||||||