Popular Woodworking 2001-06 № 122, страница 42

Learn to set up and use a matched set of router bits to create doors that are strong, easy to make and beautifully detailed. opeStick

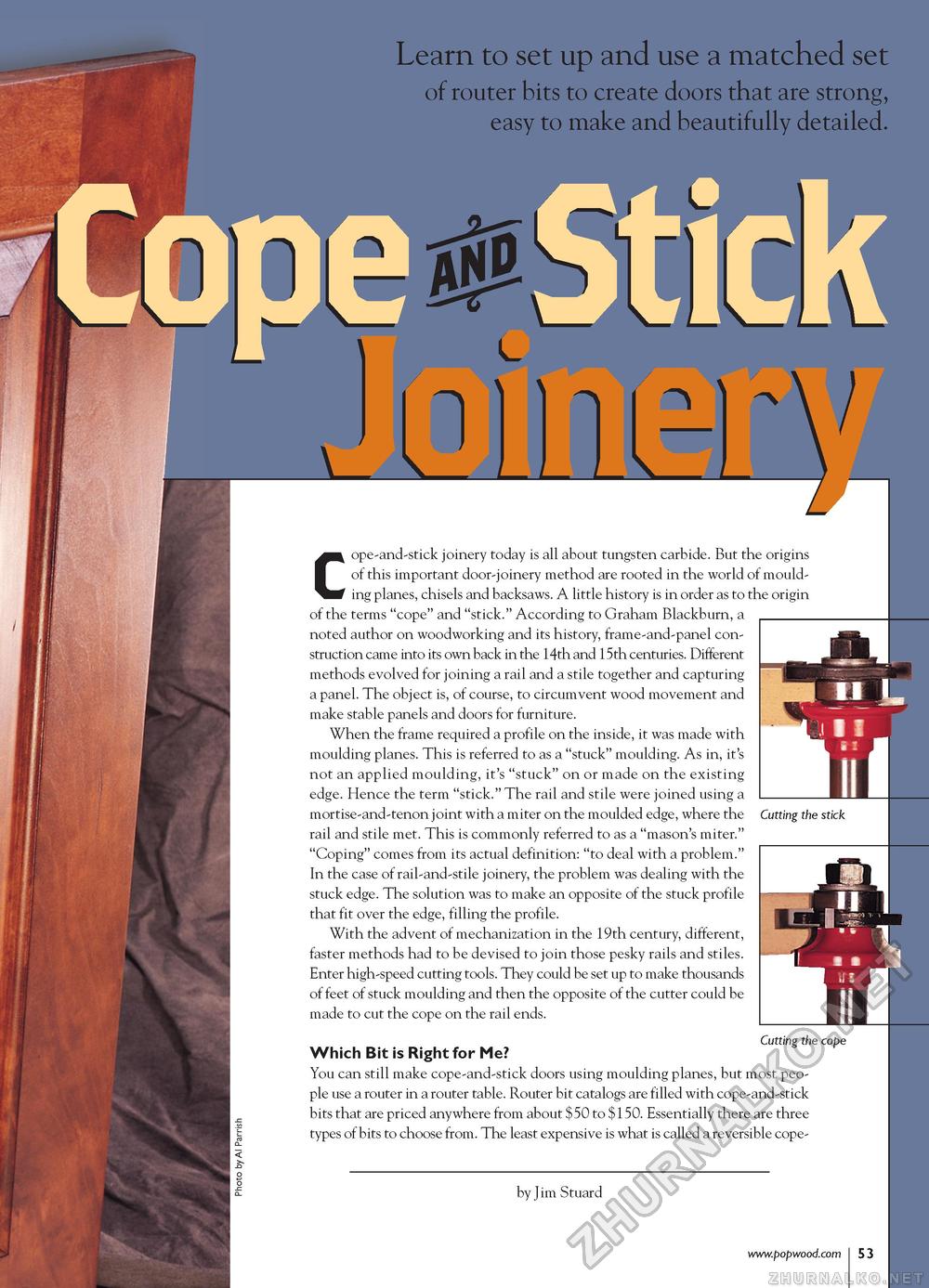

Cope-and-stick joinery today is all about tungsten carbide. But the origins of this important door-joinery method are rooted in the world of moulding planes, chisels and backsaws. A little history is in order as to the origin of the terms "cope" and "stick." According to Graham Blackburn, a noted author on woodworking and its history, frame-and-panel construction came into its own back in the 14th and 15th centuries. Different methods evolved for joining a rail and a stile together and capturing a panel. The object is, of course, to circumvent wood movement and make stable panels and doors for furniture. When the frame required a profile on the inside, it was made with moulding planes. This is referred to as a "stuck" moulding. As in, it's not an applied moulding, it's "stuck" on or made on the existing edge. Hence the term "stick." The rail and stile were joined using a mortise-and-tenon joint with a miter on the moulded edge, where the rail and stile met. This is commonly referred to as a "mason's miter." "Coping" comes from its actual definition: "to deal with a problem." In the case of rail-and-stile joinery, the problem was dealing with the stuck edge. The solution was to make an opposite of the stuck profile that fit over the edge, filling the profile. With the advent of mechanization in the 19th century, different, faster methods had to be devised to join those pesky rails and stiles. Enter high-speed cutting tools. They could be set up to make thousands of feet of stuck moulding and then the opposite of the cutter could be made to cut the cope on the rail ends. Cutting the cope Which Bit is Right for Me? You can still make cope-and-stick doors using moulding planes, but most people use a router in a router table. Router bit catalogs are filled with cope-and-stick bits that are priced anywhere from about $50 to $150. Essentially there are three types of bits to choose from. The least expensive is what is called a reversible cope- by Jim Stuard 53 |

|||||||||||||||