Popular Woodworking 2003-06 № 134, страница 77

Eternally Warping Stiles The doors use plastic panels instead of glass or wooden panels. The plastic panels we chose are typically used for building greenhouses. They're rigid, stable and durable. A 4' x 8' sheet costs only about as much as veneer-core plywood (see the supplies box), but the shipping costs are especially expensive for the Midwest and East. Using a utility knife, I cut the panels in a chevron pattern with the corrugations running at a 45° angle. It's simple work to change the pattern to make a shallower or steeper chevron, or to have the corrugations run vertically or horizontally. And if you're not looking for a contemporary look, it's easy to substitute plywood panels, glass or other material. After the project is finished, install the pan els by nailing in V4" x cleats around the rabbet in the door. The doors should be built the same way you built the frame-and-panel assemblies for the carcase: Cut your parts oversized and trim the final assembly to size after it's glued up. This will make hanging your doors easier. Another thing that will ease installation is to have doors that are flat. Making large doors is a confounding woodworking puzzle. Long and narrow stiles tend to warp or twist when ripped on the table saw. Even a little warp can prevent the stiles from lining up when the doors are shut. The first set of doors I built for this cabinet had stiles that warped more than V4". This is too much warp in my book. I built a second set of doors, and they warped about 3/32". And that you can fix. MATERIALS Maple: I used about 60 board feet of 4/4 hard white maple. Plywood: You'll need two sheets of 3/4" maple plywood, one sheet of V2" maple plywood, one sheet of V4" Baltic birch plywood and one sheet of 3/8" Baltic birch plywood. SUPPLIES Lee Valley Tools, 800-871-8158 or leevalley.com Lee Valley Tools, 800-871-8158 or leevalley.com

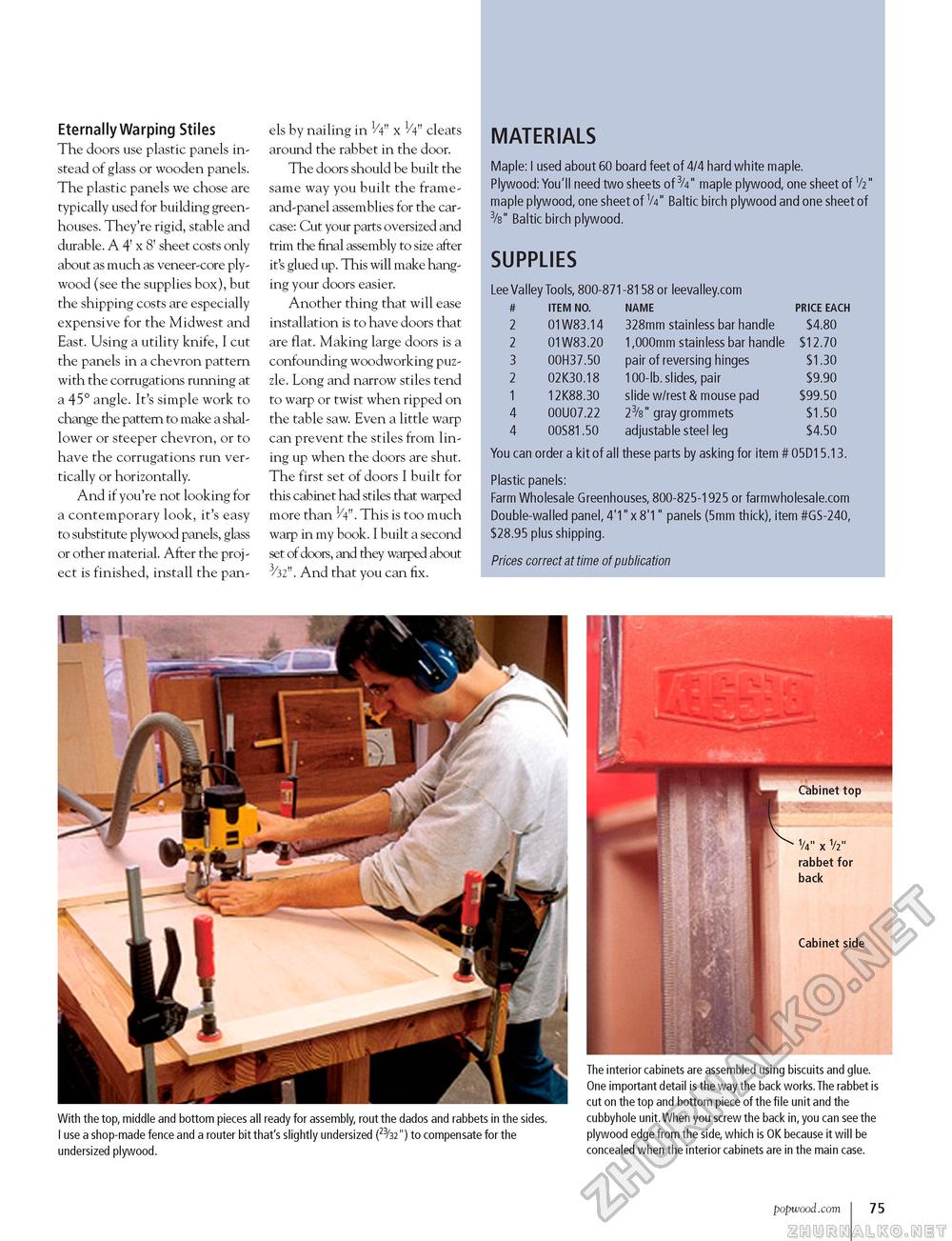

You can order a kit of all these parts by asking for item # 05D15.13. Plastic panels: Farm Wholesale Greenhouses, 800-825-1925 or farmwholesale.com Double-walled panel, 4'1" x 8'1" panels (5mm thick), item #GS-240, $28.95 plus shipping. Prices correct at time of publication With the top, middle and bottom pieces all ready for assembly, rout the dados and rabbets in the sides. I use a shop-made fence and a router bit that's slightly undersized (23/b2") to compensate for the undersized plywood. The interior cabinets are assembled using biscuits and glue. One important detail is the way the back works. The rabbet is cut on the top and bottom piece of the file unit and the cubbyhole unit. When you screw the back in, you can see the plywood edge from the side, which is OK because it will be concealed when the interior cabinets are in the main case. popwood.com 75 |