Popular Woodworking 2003-10 № 136, страница 46

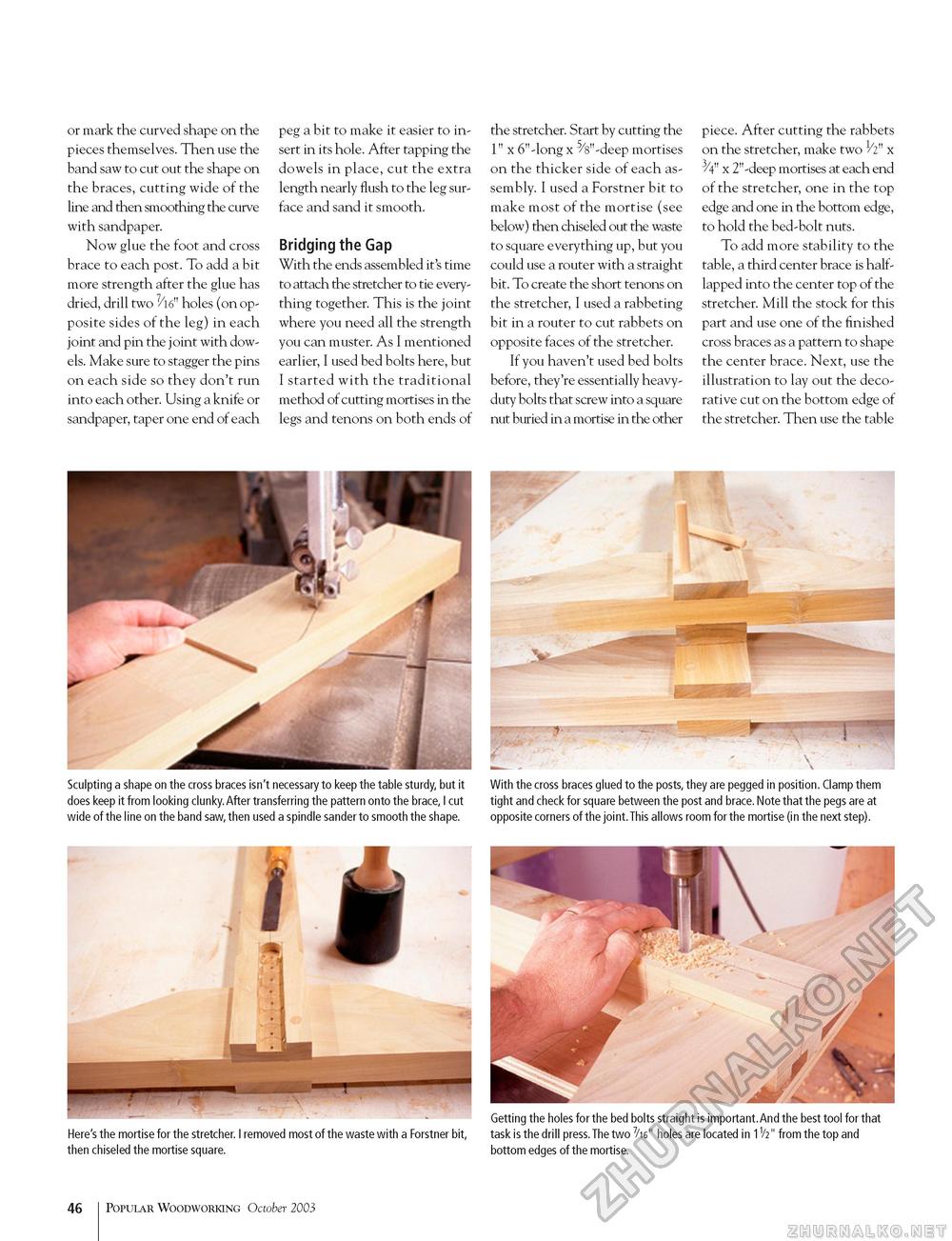

or mark the curved shape on the pieces themselves. Then use the band saw to cut out the shape on the braces, cutting wide of the line and then smoothing the curve with sandpaper. Now glue the foot and cross brace to each post. To add a bit more strength after the glue has dried, drill two 7/16" holes (on opposite sides of the leg) in each joint and pin the joint with dowels. Make sure to stagger the pins on each side so they don't run into each other. Using a knife or sandpaper, taper one end of each peg a bit to make it easier to insert in its hole. After tapping the dowels in place, cut the extra length nearly flush to the leg surface and sand it smooth. Bridging the Gap With the ends assembled it's time to attach the stretcher to tie everything together. This is the joint where you need all the strength you can muster. As I mentioned earlier, I used bed bolts here, but I started with the traditional method of cutting mortises in the legs and tenons on both ends of the stretcher. Start by cutting the 1" x 6"-long x 5/8"-deep mortises on the thicker side of each assembly. I used a Forstner bit to make most of the mortise (see below) then chiseled out the waste to square everything up, but you could use a router with a straight bit. To create the short tenons on the stretcher, I used a rabbeting bit in a router to cut rabbets on opposite faces of the stretcher. If you haven't used bed bolts before, they're essentially heavy-duty bolts that screw into a square nut buried in a mortise in the other piece. After cutting the rabbets on the stretcher, make two 1/2" x 34" x 2"-deep mortises at each end of the stretcher, one in the top edge and one in the bottom edge, to hold the bed-bolt nuts. To add more stability to the table, a third center brace is half-lapped into the center top of the stretcher. Mill the stock for this part and use one of the finished cross braces as a pattern to shape the center brace. Next, use the illustration to lay out the decorative cut on the bottom edge of the stretcher. Then use the table Sculpting a shape on the cross braces isn't necessary to keep the table sturdy, but it does keep it from looking clunky.After transferring the pattern onto the brace, I cut wide of the line on the band saw, then used a spindle sander to smooth the shape. Ii Here's the mortise for the stretcher. I removed most of the waste with a Forstner bit, then chiseled the mortise square. With the cross braces glued to the posts, they are pegged in position. Clamp them tight and check for square between the post and brace. Note that the pegs are at opposite corners of the joint.This allows room for the mortise (in the next step). Getting the holes for the bed bolts straight is important.And the best tool for that task is the drill press.The two 7/16" holes are located in 1V2" from the top and bottom edges of the mortise. 46 Popular Woodworking October 2003 |