Popular Woodworking 2003-10 № 136, страница 55

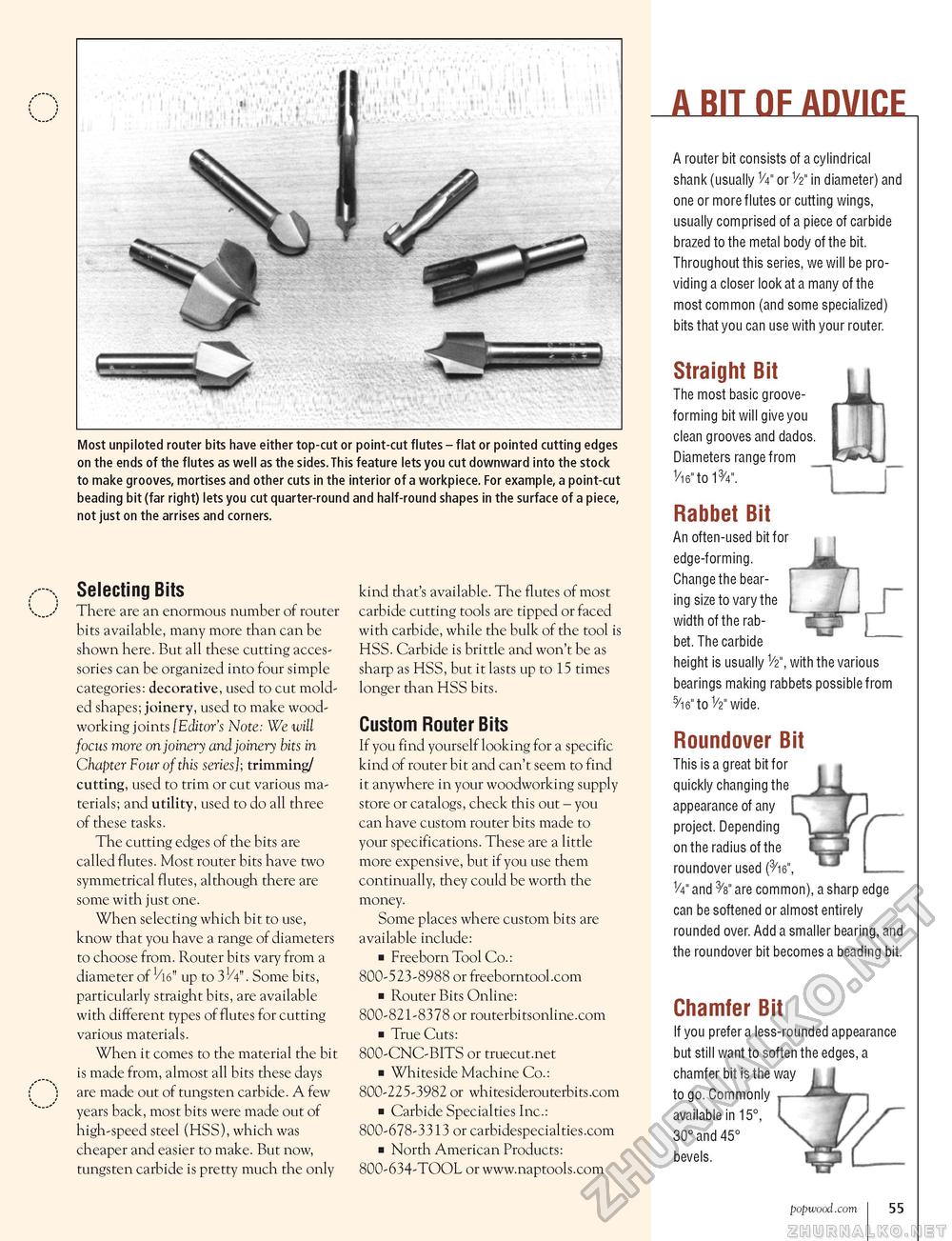

Most unpiloted router bits have either top-cut or point-cut flutes - flat or pointed cutting edges on the ends of the flutes as well as the sides. This feature lets you cut downward into the stock to make grooves, mortises and other cuts in the interior of a workpiece. For example, a point-cut beading bit (far right) lets you cut quarter-round and half-round shapes in the surface of a piece, not just on the arrises and corners. Selecting Bits There are an enormous number of router bits available, many more than can be shown here. But all these cutting accessories can be organized into four simple categories: decorative, used to cut molded shapes; joinery, used to make woodworking joints [Editor's Note: We will focus more on joinery and joinery bits in Chapter Four of this series]; trimming/ cutting, used to trim or cut various materials; and utility, used to do all three of these tasks. The cutting edges of the bits are called flutes. Most router bits have two symmetrical flutes, although there are some with just one. When selecting which bit to use, know that you have a range of diameters to choose from. Router bits vary from a diameter of 1/16" up to 31/4" . Some bits, particularly straight bits, are available with different types of flutes for cutting various materials. When it comes to the material the bit is made from, almost all bits these days are made out of tungsten carbide. A few years back, most bits were made out of high-speed steel (HSS), which was cheaper and easier to make. But now, tungsten carbide is pretty much the only kind that's available. The flutes of most carbide cutting tools are tipped or faced with carbide, while the bulk of the tool is HSS. Carbide is brittle and won't be as sharp as HSS, but it lasts up to 15 times longer than HSS bits. Custom Router Bits If you find yourself looking for a specific kind of router bit and can't seem to find it anywhere in your woodworking supply store or catalogs, check this out - you can have custom router bits made to your specifications. These are a little more expensive, but if you use them continually, they could be worth the money. Some places where custom bits are available include: ■ Freeborn Tool Co.: 800-523-8988 or freeborntool.com ■ Router Bits Online: 800-821-8378 or routerbitsonline.com ■ True Cuts: 800-CNC-BITS or truecut.net ■ Whiteside Machine Co.: 800-225-3982 or whitesiderouterbits.com ■ Carbide Specialties Inc.: 800-678-3313 or carbidespecialties.com ■ North American Products: 800-634-T00L or www.naptools.com A BIT OF ADVICE A router bit consists of a cylindrical shank (usually V4" or V2" in diameter) and one or more flutes or cutting wings, usually comprised of a piece of carbide brazed to the metal body of the bit. Throughout this series, we will be providing a closer look at a many of the most common (and some specialized) bits that you can use with your router. Straight Bit The most basic groove-forming bit will give you clean grooves and dados. Diameters range from VlB" to 13/4". Rabbet Bit An often-used bit for edge-forming. Change the bearing size to vary the width of the rabbet. The carbide height is usually 1/2", with the various bearings making rabbets possible from 5/i6" to V2" wide. Roundover Bit This is a great bit for quickly changing the appearance of any project. Depending on the radius of the roundover used (3/i6M V4" and 3/8" are common), a sharp edge can be softened or almost entirely rounded over. Add a smaller bearing, and the roundover bit becomes a beading bit. Chamfer Bit If you prefer a less-rounded appearance but still want to soften the edges, a chamfer bit is the way to go. Commonly available in 15°, 30° and 45° bevels. popwood.com 55 |