Popular Woodworking 2003-10 № 136, страница 53

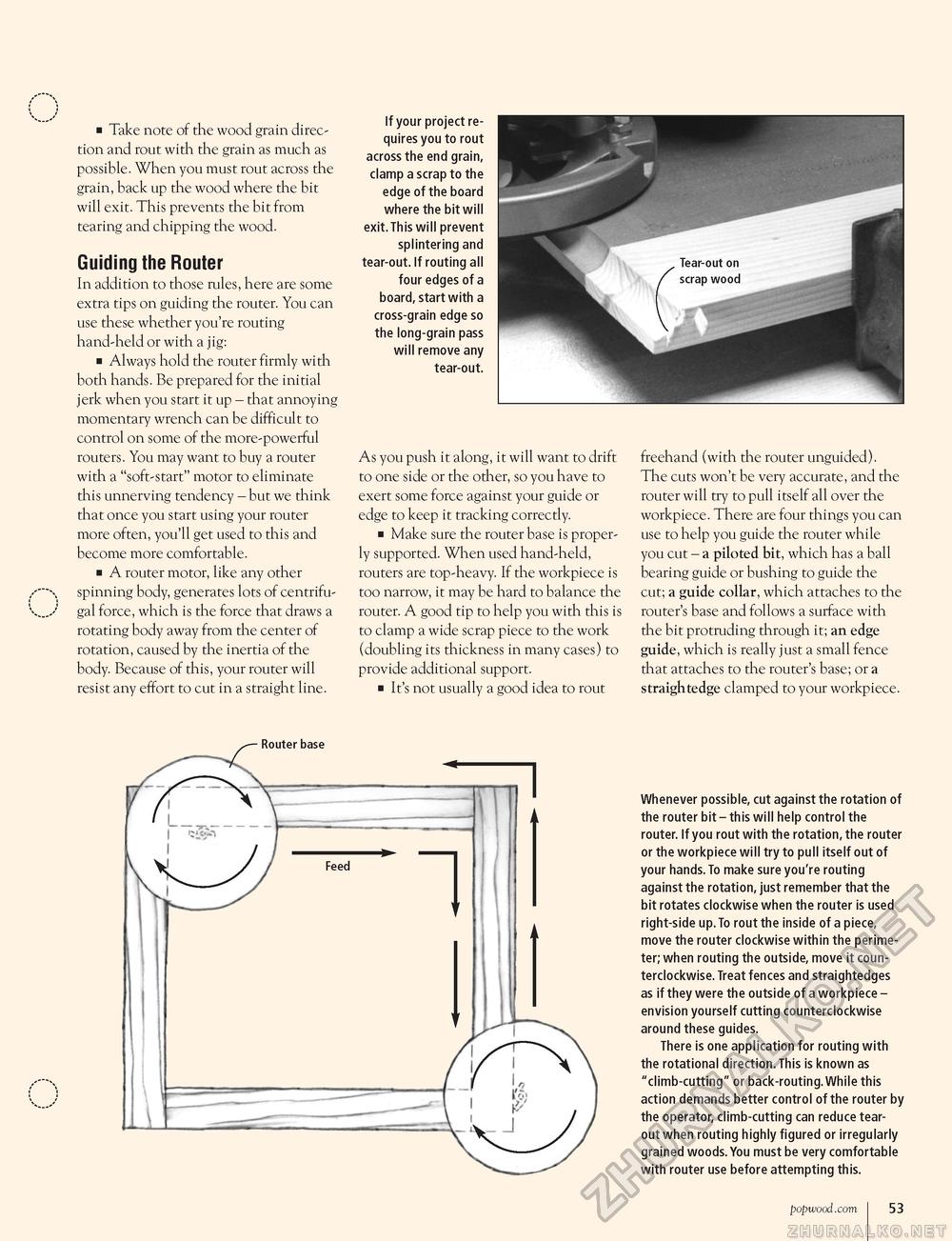

If your project requires you to rout across the end grain, clamp a scrap to the edge of the board where the bit will exit.This will prevent splintering and tear-out. If routing all four edges of a board, start with a cross-grain edge so the long-grain pass will remove any tear-out. ■ Take note of the wood grain direction and rout with the grain as much as possible. When you must rout across the grain, back up the wood where the bit will exit. This prevents the bit from tearing and chipping the wood. Guiding the Router In addition to those rules, here are some extra tips on guiding the router. You can use these whether you're routing hand-held or with a jig: ■ Always hold the router firmly with both hands. Be prepared for the initial jerk when you start it up - that annoying momentary wrench can be difficult to control on some of the more-powerful routers. You may want to buy a router with a "soft-start" motor to eliminate this unnerving tendency - but we think that once you start using your router more often, you'll get used to this and become more comfortable. ■ A router motor, like any other spinning body, generates lots of centrifugal force, which is the force that draws a rotating body away from the center of rotation, caused by the inertia of the body. Because of this, your router will resist any effort to cut in a straight line. As you push it along, it will want to drift to one side or the other, so you have to exert some force against your guide or edge to keep it tracking correctly. ■ Make sure the router base is properly supported. When used hand-held, routers are top-heavy. If the workpiece is too narrow, it may be hard to balance the router. A good tip to help you with this is to clamp a wide scrap piece to the work (doubling its thickness in many cases) to provide additional support. ■ It's not usually a good idea to rout freehand (with the router unguided). The cuts won't be very accurate, and the router will try to pull itself all over the workpiece. There are four things you can use to help you guide the router while you cut - a piloted bit, which has a ball bearing guide or bushing to guide the cut; a guide collar, which attaches to the router's base and follows a surface with the bit protruding through it; an edge guide, which is really just a small fence that attaches to the router's base; or a straightedge clamped to your workpiece. Whenever possible, cut against the rotation of the router bit - this will help control the router. If you rout with the rotation, the router or the workpiece will try to pull itself out of your hands. To make sure you're routing against the rotation, just remember that the bit rotates clockwise when the router is used right-side up. To rout the inside of a piece, move the router clockwise within the perimeter; when routing the outside, move it counterclockwise. Treat fences and straightedges as if they were the outside of a workpiece -envision yourself cutting counterclockwise around these guides. There is one application for routing with the rotational direction. This is known as "climb-cutting" or back-routing. While this action demands better control of the router by the operator, climb-cutting can reduce tear-out when routing highly figured or irregularly grained woods. You must be very comfortable with router use before attempting this. popwood.com 53 |