Popular Woodworking 2003-10 № 136, страница 50

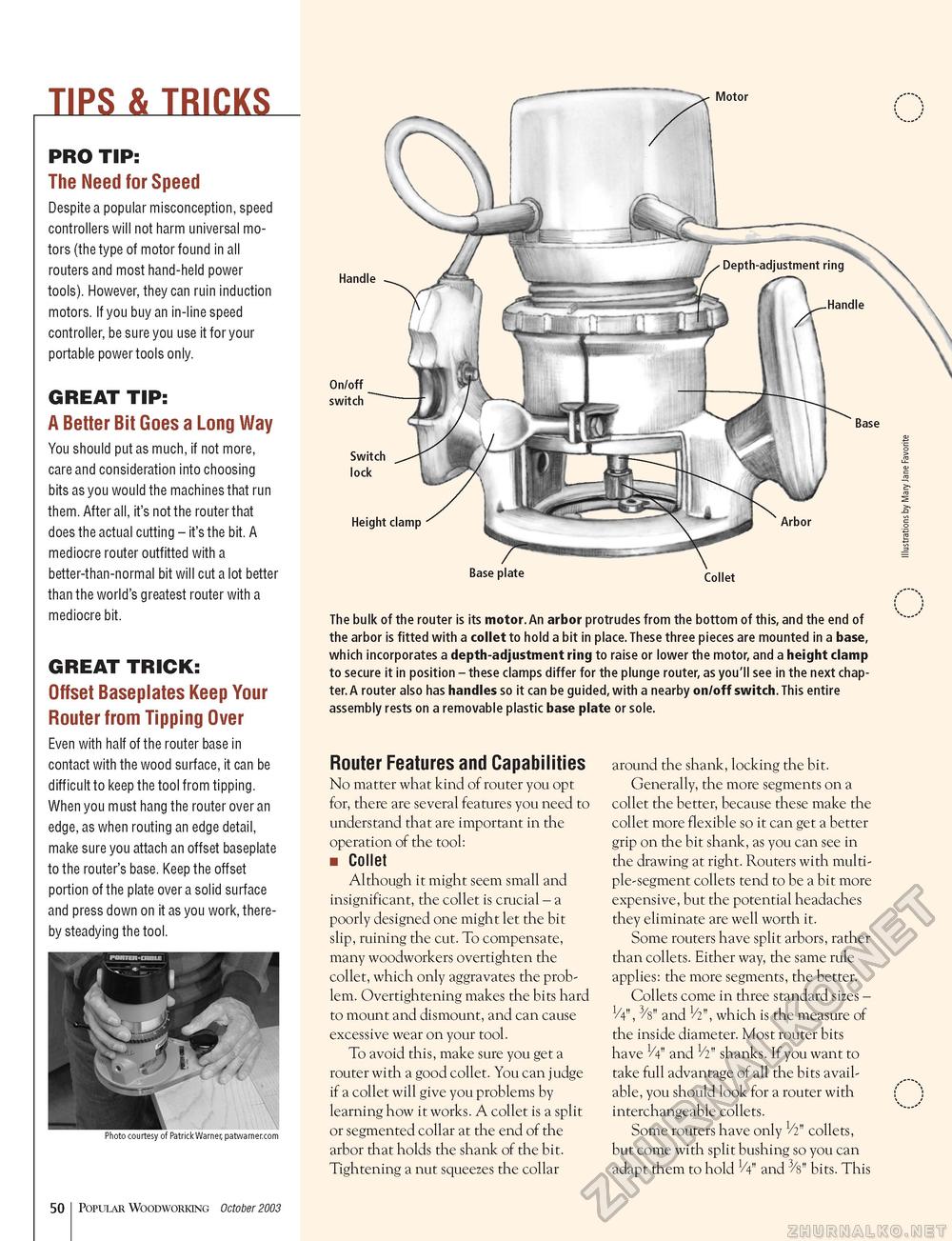

TIPS & TRICKS PRO TIP: The Need for Speed Despite a popular misconception, speed controllers will not harm universal motors (the type of motor found in all routers and most hand-held power tools). However, they can ruin induction motors. If you buy an in-line speed controller, be sure you use it for your portable power tools only. GREAT TIP: A Better Bit Goes a Long Way You should put as much, if not more, care and consideration into choosing bits as you would the machines that run them. After all, it's not the router that does the actual cutting - it's the bit. A mediocre router outfitted with a better-than-normal bit will cut a lot better than the world's greatest router with a mediocre bit. GREAT TRICK: Offset Baseplates Keep Your Router from Tipping Over Even with half of the router base in contact with the wood surface, it can be difficult to keep the tool from tipping. When you must hang the router over an edge, as when routing an edge detail, make sure you attach an offset baseplate to the router's base. Keep the offset portion of the plate over a solid surface and press down on it as you work, thereby steadying the tool. Photo courtesy of Patrick Warner, patwarner.com The bulk of the router is its motor. An arbor protrudes from the bottom of this, and the end of the arbor is fitted with a collet to hold a bit in place. These three pieces are mounted in a base, which incorporates a depth-adjustment ring to raise or lower the motor, and a height clamp to secure it in position - these clamps differ for the plunge router, as you'll see in the next chap-ter.A router also has handles so it can be guided, with a nearby on/off switch. This entire assembly rests on a removable plastic base plate or sole. Router Features and Capabilities No matter what kind of router you opt for, there are several features you need to understand that are important in the operation of the tool: ■ Collet Although it might seem small and insignificant, the collet is crucial - a poorly designed one might let the bit slip, ruining the cut. To compensate, many woodworkers overtighten the collet, which only aggravates the problem. Overtightening makes the bits hard to mount and dismount, and can cause excessive wear on your tool. To avoid this, make sure you get a router with a good collet. You can judge if a collet will give you problems by learning how it works. A collet is a split or segmented collar at the end of the arbor that holds the shank of the bit. Tightening a nut squeezes the collar around the shank, locking the bit. Generally, the more segments on a collet the better, because these make the collet more flexible so it can get a better grip on the bit shank, as you can see in the drawing at right. Routers with multiple-segment collets tend to be a bit more expensive, but the potential headaches they eliminate are well worth it. Some routers have split arbors, rather than collets. Either way, the same rule applies: the more segments, the better. Collets come in three standard sizes -1/4", 3/s" and V, which is the measure of the inside diameter. Most router bits have 1/4" and 1/2" shanks. If you want to take full advantage of all the bits available, you should look for a router with interchangeable collets. Some routers have only 1/2" collets, but come with split bushing so you can adapt them to hold 1/4" and 3/s" bits. This 50 Popular Woodworking October 2003 |