Popular Woodworking 2003-10 № 136, страница 51

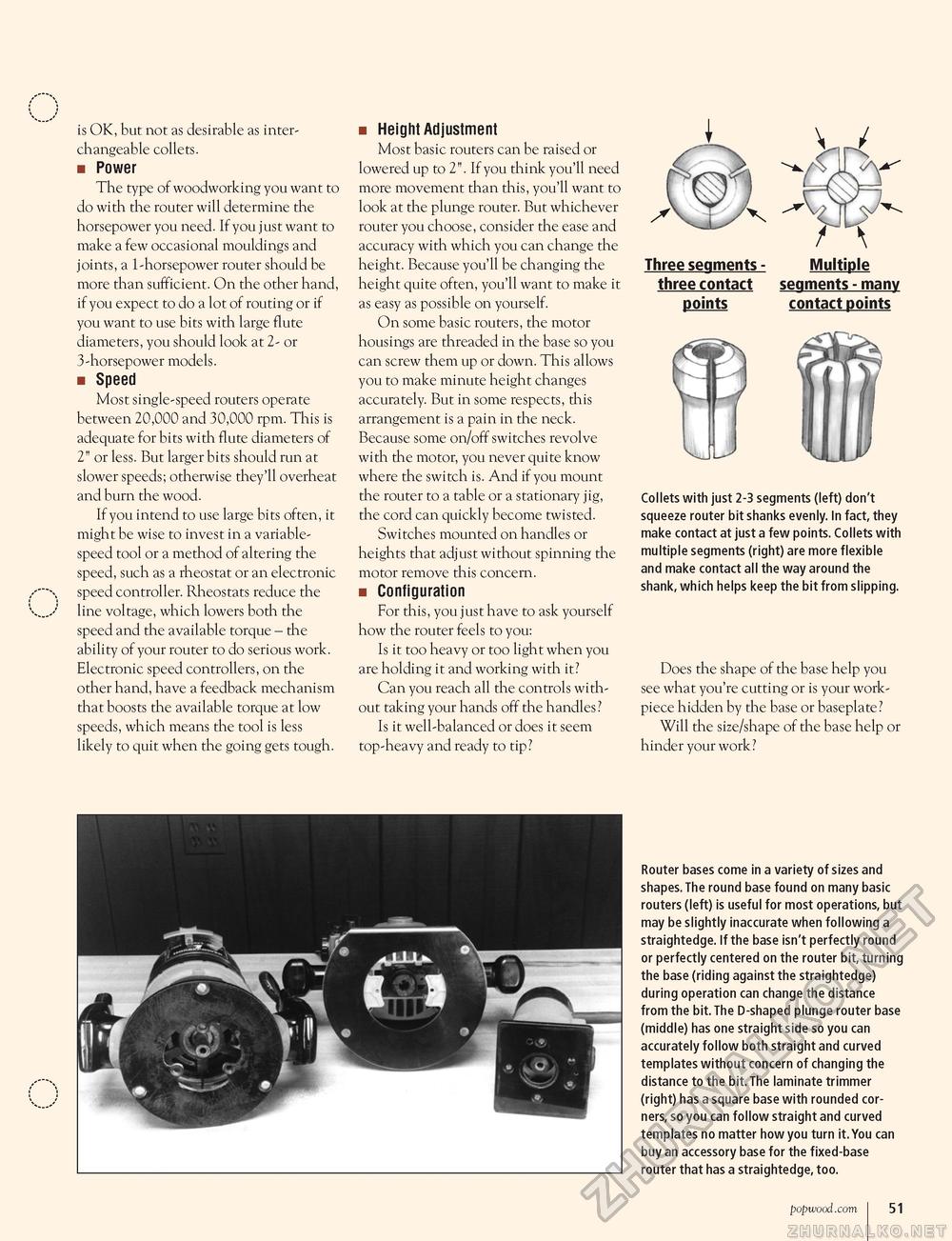

is OK, but not as desirable as interchangeable collets. ■ Power The type of woodworking you want to do with the router will determine the horsepower you need. If you just want to make a few occasional mouldings and joints, a 1-horsepower router should be more than sufficient. On the other hand, if you expect to do a lot of routing or if you want to use bits with large flute diameters, you should look at 2- or 3-horsepower models. ■ Speed Most single-speed routers operate between 20,000 and 30,000 rpm. This is adequate for bits with flute diameters of 2" or less. But larger bits should run at slower speeds; otherwise they'll overheat and burn the wood. If you intend to use large bits often, it might be wise to invest in a variable-speed tool or a method of altering the speed, such as a rheostat or an electronic speed controller. Rheostats reduce the line voltage, which lowers both the speed and the available torque - the ability of your router to do serious work. Electronic speed controllers, on the other hand, have a feedback mechanism that boosts the available torque at low speeds, which means the tool is less likely to quit when the going gets tough. ■ Height Adjustment Most basic routers can be raised or lowered up to 2". If you think you'll need more movement than this, you'll want to look at the plunge router. But whichever router you choose, consider the ease and accuracy with which you can change the height. Because you'll be changing the height quite often, you'll want to make it as easy as possible on yourself. On some basic routers, the motor housings are threaded in the base so you can screw them up or down. This allows you to make minute height changes accurately. But in some respects, this arrangement is a pain in the neck. Because some on/off switches revolve with the motor, you never quite know where the switch is. And if you mount the router to a table or a stationary jig, the cord can quickly become twisted. Switches mounted on handles or heights that adjust without spinning the motor remove this concern. ■ Configuration For this, you just have to ask yourself how the router feels to you: Is it too heavy or too light when you are holding it and working with it? Can you reach all the controls without taking your hands off the handles? Is it well-balanced or does it seem top-heavy and ready to tip? Three segments -three contact points Multiple segments - many contact points Collets with just 2-3 segments (left) don't squeeze router bit shanks evenly. In fact, they make contact at just a few points. Collets with multiple segments (right) are more flexible and make contact all the way around the shank, which helps keep the bit from slipping. Does the shape of the base help you see what you're cutting or is your work-piece hidden by the base or baseplate? Will the size/shape of the base help or hinder your work? Router bases come in a variety of sizes and shapes. The round base found on many basic routers (left) is useful for most operations, but may be slightly inaccurate when following a straightedge. If the base isn't perfectly round or perfectly centered on the router bit, turning the base (riding against the straightedge) during operation can change the distance from the bit. The D-shaped plunge router base (middle) has one straight side so you can accurately follow both straight and curved templates without concern of changing the distance to the bit. The laminate trimmer (right) has a square base with rounded corners, so you can follow straight and curved templates no matter how you turn it.You can buy an accessory base for the fixed-base router that has a straightedge, too. popwood.com 51 |