Popular Woodworking 2003-10 № 136, страница 54

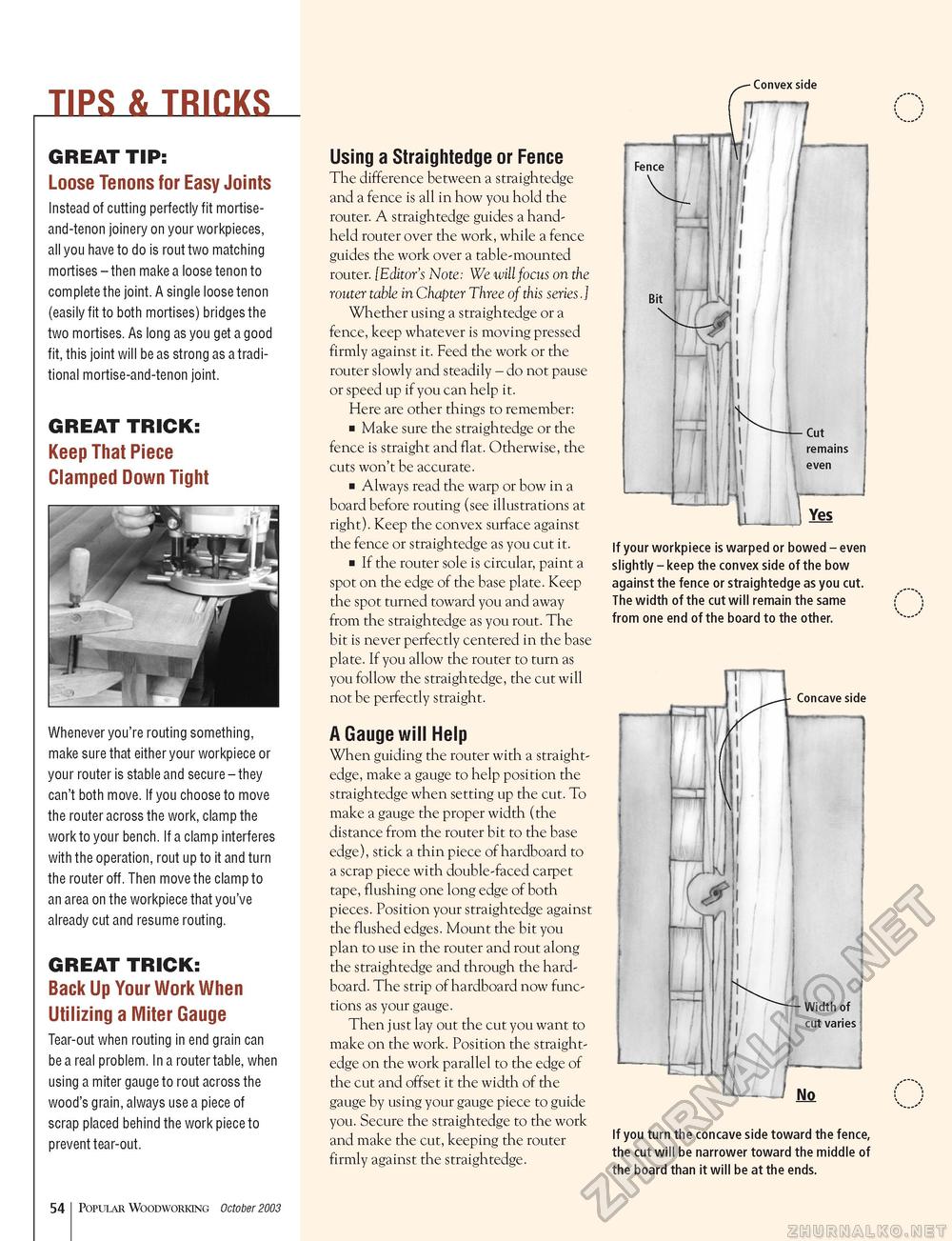

TIPS & TRICKS GREAT TIP: Loose Tenons for Easy Joints Instead of cutting perfectly fit mortise-and-tenon joinery on your workpieces, all you have to do is rout two matching mortises - then make a loose tenon to complete the joint. A single loose tenon (easily fit to both mortises) bridges the two mortises. As long as you get a good fit, this joint will be as strong as a traditional mortise-and-tenon joint. GREAT TRICK: Keep That Piece Clamped Down Tight Whenever you're routing something, make sure that either your workpiece or your router is stable and secure - they can't both move. If you choose to move the router across the work, clamp the work to your bench. If a clamp interferes with the operation, rout up to it and turn the router off. Then move the clamp to an area on the workpiece that you've already cut and resume routing. GREAT TRICK: Back Up Your Work When Utilizing a Miter Gauge Tear-out when routing in end grain can be a real problem. In a router table, when using a miter gauge to rout across the wood's grain, always use a piece of scrap placed behind the work piece to prevent tear-out. Using a Straightedge or Fence The difference between a straightedge and a fence is all in how you hold the router. A straightedge guides a handheld router over the work, while a fence guides the work over a table-mounted router. [Editor's Note: We will focus on the router table in Chapter Three of this series.] Whether using a straightedge or a fence, keep whatever is moving pressed firmly against it. Feed the work or the router slowly and steadily - do not pause or speed up if you can help it. Here are other things to remember: ■ Make sure the straightedge or the fence is straight and flat. Otherwise, the cuts won't be accurate. ■ Always read the warp or bow in a board before routing (see illustrations at right). Keep the convex surface against the fence or straightedge as you cut it. ■ If the router sole is circular, paint a spot on the edge of the base plate. Keep the spot turned toward you and away from the straightedge as you rout. The bit is never perfectly centered in the base plate. If you allow the router to turn as you follow the straightedge, the cut will not be perfectly straight. A Gauge will Help When guiding the router with a straightedge, make a gauge to help position the straightedge when setting up the cut. To make a gauge the proper width (the distance from the router bit to the base edge), stick a thin piece of hardboard to a scrap piece with double-faced carpet tape, flushing one long edge of both pieces. Position your straightedge against the flushed edges. Mount the bit you plan to use in the router and rout along the straightedge and through the hard-board. The strip of hardboard now functions as your gauge. Then just lay out the cut you want to make on the work. Position the straightedge on the work parallel to the edge of the cut and offset it the width of the gauge by using your gauge piece to guide you. Secure the straightedge to the work and make the cut, keeping the router firmly against the straightedge. If your workpiece is warped or bowed - even slightly - keep the convex side of the bow against the fence or straightedge as you cut. The width of the cut will remain the same from one end of the board to the other. If you turn the concave side toward the fence, the cut will be narrower toward the middle of the board than it will be at the ends. 54 Popular Woodworking October 2003 |