Popular Woodworking 2004-02 № 139, страница 92

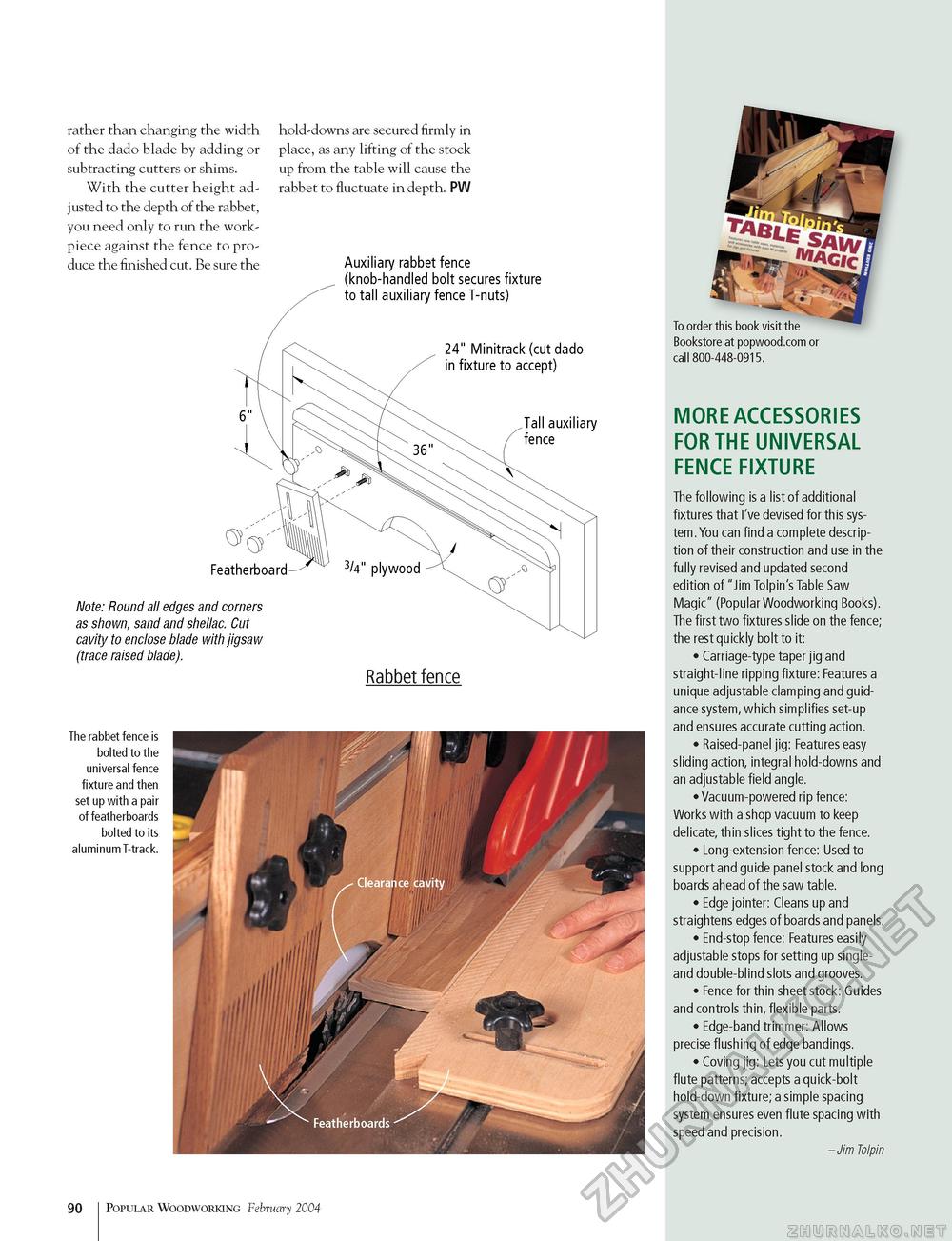

rather than changing the width of the dado blade by adding or subtracting cutters or shims. With the cutter height adjusted to the depth of the rabbet, you need only to run the work-piece against the fence to produce the finished cut. Be sure the hold-downs are secured firmly in place, as any lifting of the stock up from the table will cause the rabbet to fluctuate in depth. PW Auxiliary rabbet fence (knob-handled bolt secures fixture to tall auxiliary fence T-nuts) Featherboard Note: Round all edges and corners as shown, sand and shellac. Cut cavity to enclose blade with jigsaw (trace raised blade). 24" Minitrack (cut dado in fixture to accept) Tall auxiliary fence Rabbet fence The rabbet fence is bolted to the universal fence fixture and then set up with a pair offeatherboards bolted to its aluminum T-track. Bookstore at popwood.com or call 800-448-0915. MORE ACCESSORIES FOR THE UNIVERSAL FENCE FIXTURE The following is a list of additional fixtures that I've devised for this sys-tem.You can find a complete description of their construction and use in the fully revised and updated second edition of "Jim Tolpin's Table Saw Magic" (Popular Woodworking Books). The first two fixtures slide on the fence; the rest quickly bolt to it: • Carriage-type taper jig and straight-line ripping fixture: Features a unique adjustable clamping and guidance system, which simplifies set-up and ensures accurate cutting action. • Raised-panel jig: Features easy sliding action, integral hold-downs and an adjustable field angle. • Vacuum-powered rip fence: Works with a shop vacuum to keep delicate, thin slices tight to the fence. • Long-extension fence: Used to support and guide panel stock and long boards ahead of the saw table. • Edge jointer: Cleans up and straightens edges of boards and panels. • End-stop fence: Features easily adjustable stops for setting up single-and double-blind slots and grooves. • Fence for thin sheet stock: Guides and controls thin, flexible parts. • Edge-band trimmer: Allows precise flushing of edge bandings. • Coving jig: Lets you cut multiple flute patterns; accepts a quick-bolt hold-down fixture; a simple spacing system ensures even flute spacing with speed and precision. - Jim Tolpin 90 Popular Woodworking February 2004 |