Popular Woodworking 2004-06 № 141, страница 48

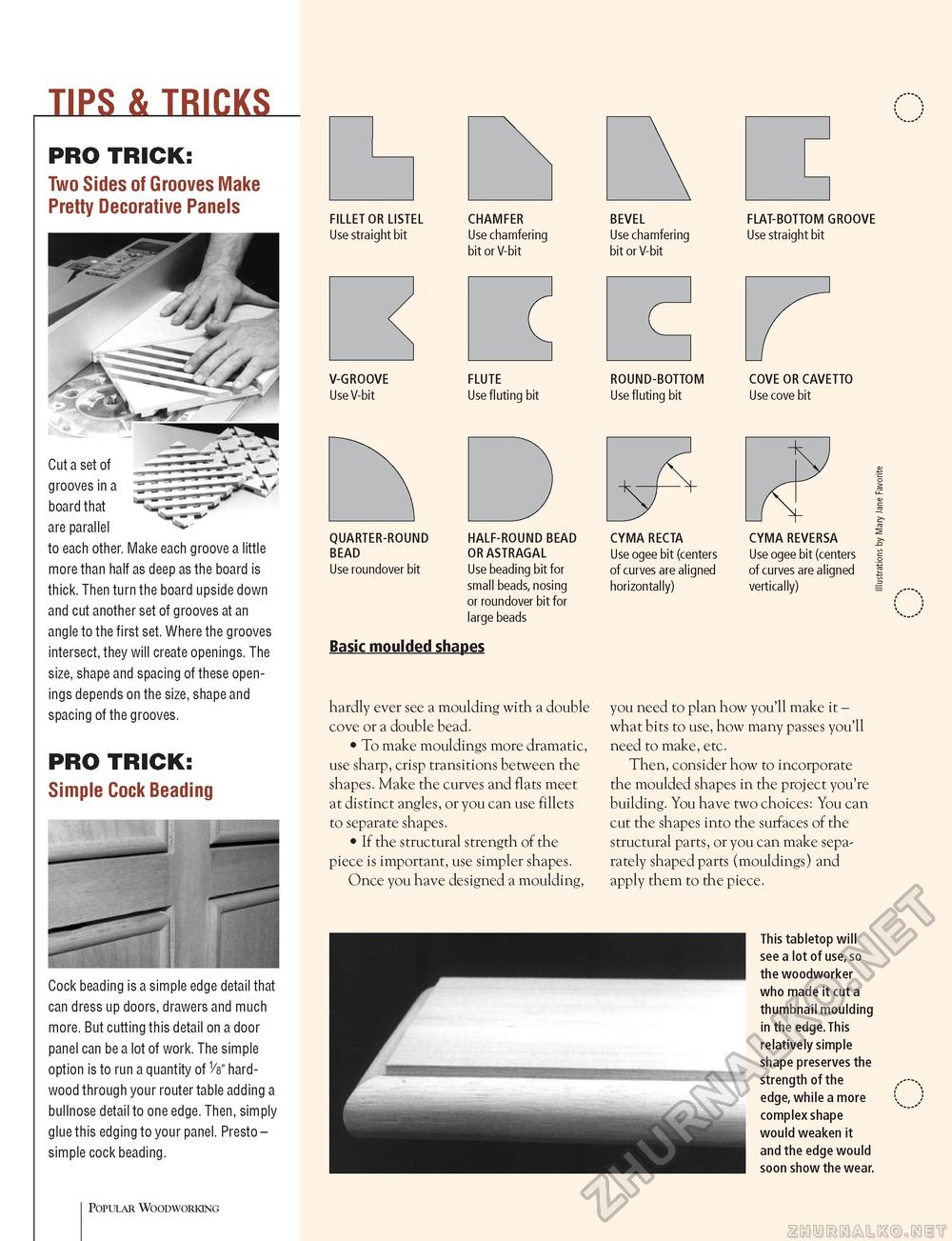

TIPS & TRICKS PRO TRICK: Two Sides of Grooves Make Pretty Decorative Panels are parallel ^ to each other. Make each groove a little more than half as deep as the board is thick. Then turn the board upside down and cut another set of grooves at an angle to the first set. Where the grooves intersect, they will create openings. The size, shape and spacing of these openings depends on the size, shape and spacing of the grooves. PRO TRICK: Simple Cock Beading Cock beading is a simple edge detail that can dress up doors, drawers and much more. But cutting this detail on a door panel can be a lot of work. The simple option is to run a quantity of Vs" hardwood through your router table adding a bullnose detail to one edge. Then, simply glue this edging to your panel. Presto -simple cock beading. FILLET OR LISTEL Use straight bit CHAMFER Use chamfering bit or V-bit BEVEL Use chamfering bit or V-bit FLAT-BOTTOM GROOVE Use straight bit V-GROOVE Use V-bit FLUTE Use fluting bit ROUND-BOTTOM Use fluting bit COVE OR CAVETTO Use cove bit QUARTER-ROUND HALF-ROUND BEAD BEAD OR ASTRAGAL Use roundover bit Use beading bit for small beads, nosing or roundover bit for large beads Basic moulded shapes CYMA RECTA CYMA REVERSA Use ogee bit (centers Use ogee bit (centers of curves are aligned of curves are aligned horizontally) vertically) hardly ever see a moulding with a double cove or a double bead. • To make mouldings more dramatic, use sharp, crisp transitions between the shapes. Make the curves and flats meet at distinct angles, or you can use fillets to separate shapes. • If the structural strength of the piece is important, use simpler shapes. Once you have designed a moulding, you need to plan how you'll make it -what bits to use, how many passes you'll need to make, etc. Then, consider how to incorporate the moulded shapes in the project you're building. You have two choices: You can cut the shapes into the surfaces of the structural parts, or you can make separately shaped parts (mouldings) and apply them to the piece. This tabletop will see a lot of use, so the woodworker who made it cut a thumbnail moulding in the edge.This relatively simple shape preserves the strength of the edge, while a more complex shape would weaken it and the edge would soon show the wear. Popular Woodworking |