Popular Woodworking 2004-06 № 141, страница 49

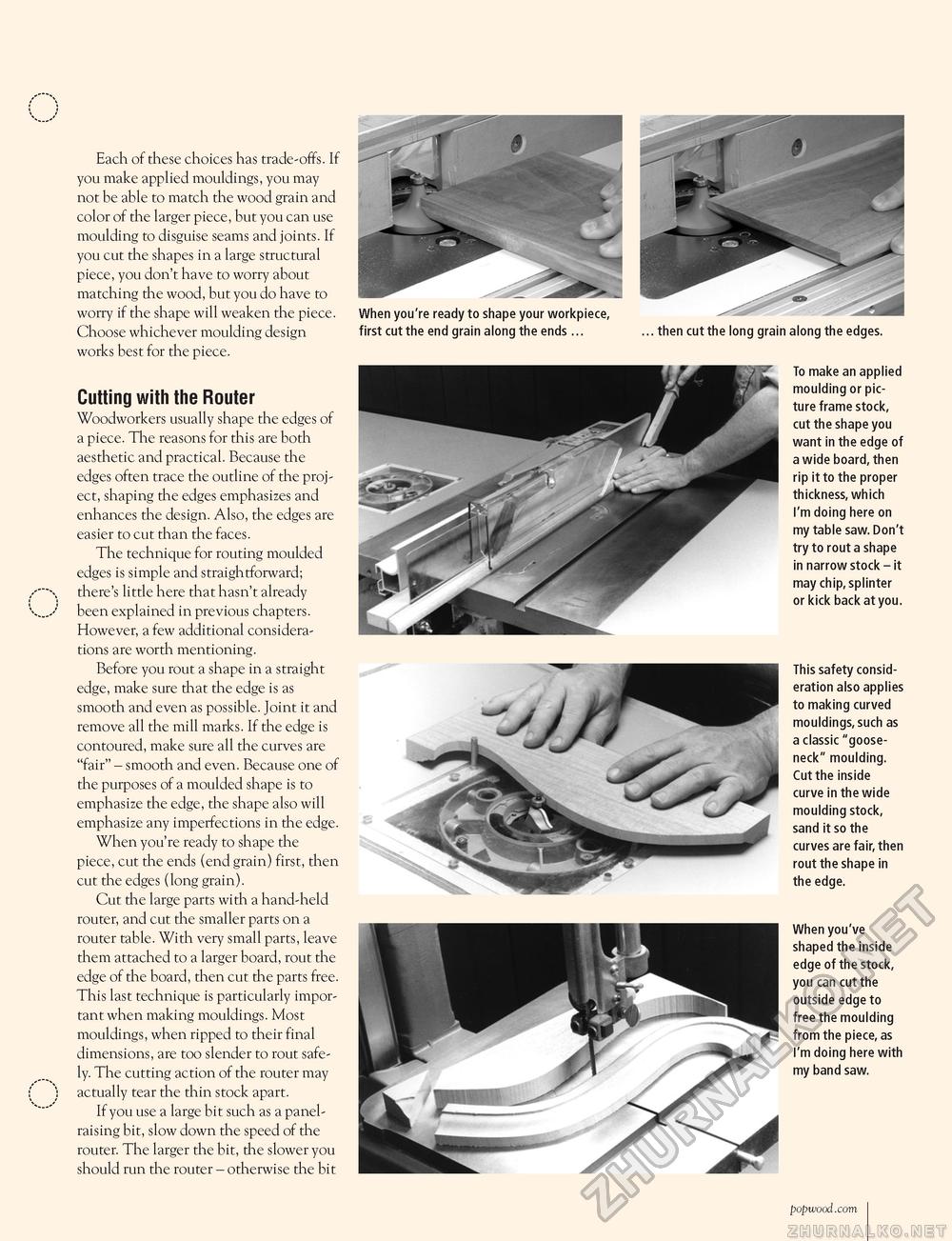

Each of these choices has trade-offs. If you make applied mouldings, you may not be able to match the wood grain and color of the larger piece, but you can use moulding to disguise seams and joints. If you cut the shapes in a large structural piece, you don't have to worry about matching the wood, but you do have to worry if the shape will weaken the piece. Choose whichever moulding design works best for the piece. Cutting with the Router Woodworkers usually shape the edges of a piece. The reasons for this are both aesthetic and practical. Because the edges often trace the outline of the project, shaping the edges emphasizes and enhances the design. Also, the edges are easier to cut than the faces. The technique for routing moulded edges is simple and straightforward; there's little here that hasn't already been explained in previous chapters. However, a few additional considerations are worth mentioning. Before you rout a shape in a straight edge, make sure that the edge is as smooth and even as possible. Joint it and remove all the mill marks. If the edge is contoured, make sure all the curves are "fair" - smooth and even. Because one of the purposes of a moulded shape is to emphasize the edge, the shape also will emphasize any imperfections in the edge. When you're ready to shape the piece, cut the ends (end grain) first, then cut the edges (long grain). Cut the large parts with a hand-held router, and cut the smaller parts on a router table. With very small parts, leave them attached to a larger board, rout the edge of the board, then cut the parts free. This last technique is particularly important when making mouldings. Most mouldings, when ripped to their final dimensions, are too slender to rout safely. The cutting action of the router may actually tear the thin stock apart. If you use a large bit such as a panel-raising bit, slow down the speed of the router. The larger the bit, the slower you should run the router - otherwise the bit When you're ready to shape your workpiece first cut the end grain along the ends ... . then cut the long grain along the edges. To make an applied moulding or picture frame stock, cut the shape you want in the edge of a wide board, then rip it to the proper thickness, which I'm doing here on my table saw. Don't try to rout a shape in narrow stock - it may chip, splinter or kick back at you. This safety consideration also applies to making curved mouldings, such as a classic "gooseneck" moulding. Cut the inside curve in the wide moulding stock, sand it so the curves are fair, then rout the shape in the edge. When you've shaped the inside edge of the stock, you can cut the outside edge to free the moulding from the piece, as I'm doing here with my band saw. popwood.com 49 |