Popular Woodworking 2005-04 № 147, страница 42

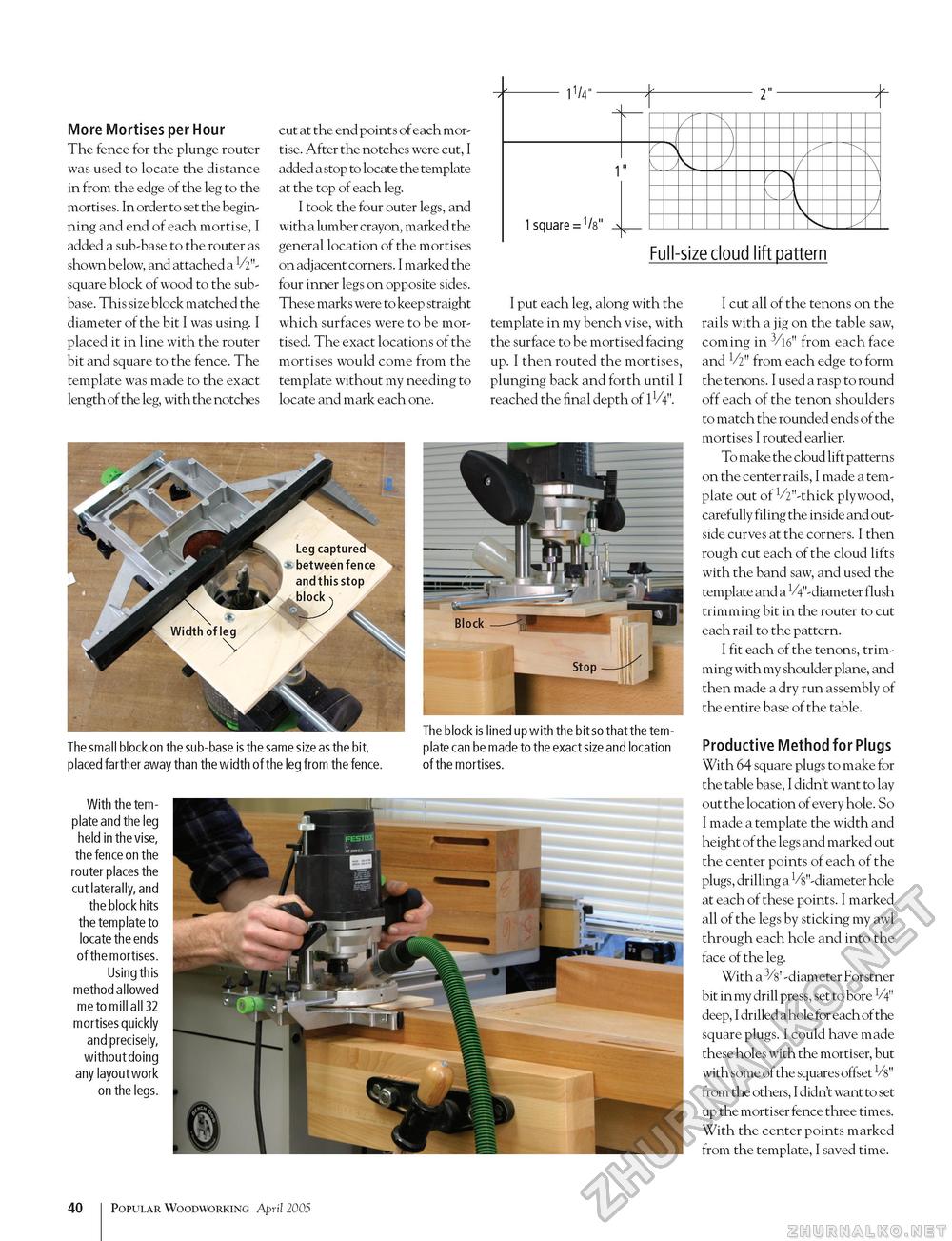

Full-size cloud lift pattern More Mortises per Hour The fence for the plunge router was used to locate the distance in from the edge of the leg to the mortises. In order to set the beginning and end of each mortise, I added a sub-base to the router as shown below, and attached a 1/2"-square block of wood to the sub-base. This size block matched the diameter of the bit I was using. I placed it in line with the router bit and square to the fence. The template was made to the exact length of the leg, with the notches The small block on the sub-base is placed farther away than the widtl cut at the end points of each mortise. After the notches were cut, I added a stop to locate the template at the top of each leg. I took the four outer legs, and with a lumber crayon, marked the general location of the mortises on adjacent corners. I marked the four inner legs on opposite sides. These marks were to keep straight which surfaces were to be mortised. The exact locations of the mortises would come from the template without my needing to locate and mark each one. ie size as the bit, leg from the fence. I put each leg, along with the template in my bench vise, with the surface to be mortised facing up. I then routed the mortises, plunging back and forth until I reached the final depth of IV4". I cut all of the tenons on the rails with a jig on the table saw, coming in 3/l6" from each face and V2" from each edge to form the tenons. I used a rasp to round off each of the tenon shoulders to match the rounded ends of the mortises I routed earlier. To make the cloud lift patterns on the center rails, I made a template out of V2"-thick plywood, carefully filing the inside and outside curves at the corners. I then rough cut each of the cloud lifts with the band saw, and used the template and a 1/4"-diameter flush trimming bit in the router to cut each rail to the pattern. I fit each of the tenons, trimming with my shoulder plane, and then made a dry run assembly of the entire base of the table. Productive Method for Plugs With 64 square plugs to make for the table base, I didn't want to lay out the location of every hole. So I made a template the width and height of the legs and marked out the center points of each of the plugs, drilling a 1/s"-diameter hole at each of these points. I marked all of the legs by sticking my awl through each hole and into the face of the leg. With a 3/8"-diameter Forstner bit in my drill press, set to bore 1/ deep, I drilled a hole for each of the square plugs. I could have made these holes with the mortiser, but with some of the squares offset Vs" from the others, I didn't want to set up the mortiser fence three times. With the center points marked from the template, I saved time. The block is lined up with the bit so that the template can be made to the exact size and location of the mortises. With the template and the leg held in the vise, the fence on the router places the cut laterally, and the block hits the template to locate the ends of the mortises. Using this method allowed me to mill all 32 mortises quickly and precisely, without doing any layout work on the legs. 40 1 Popular Woodworking April 2005 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||