Popular Woodworking 2005-04 № 147, страница 72

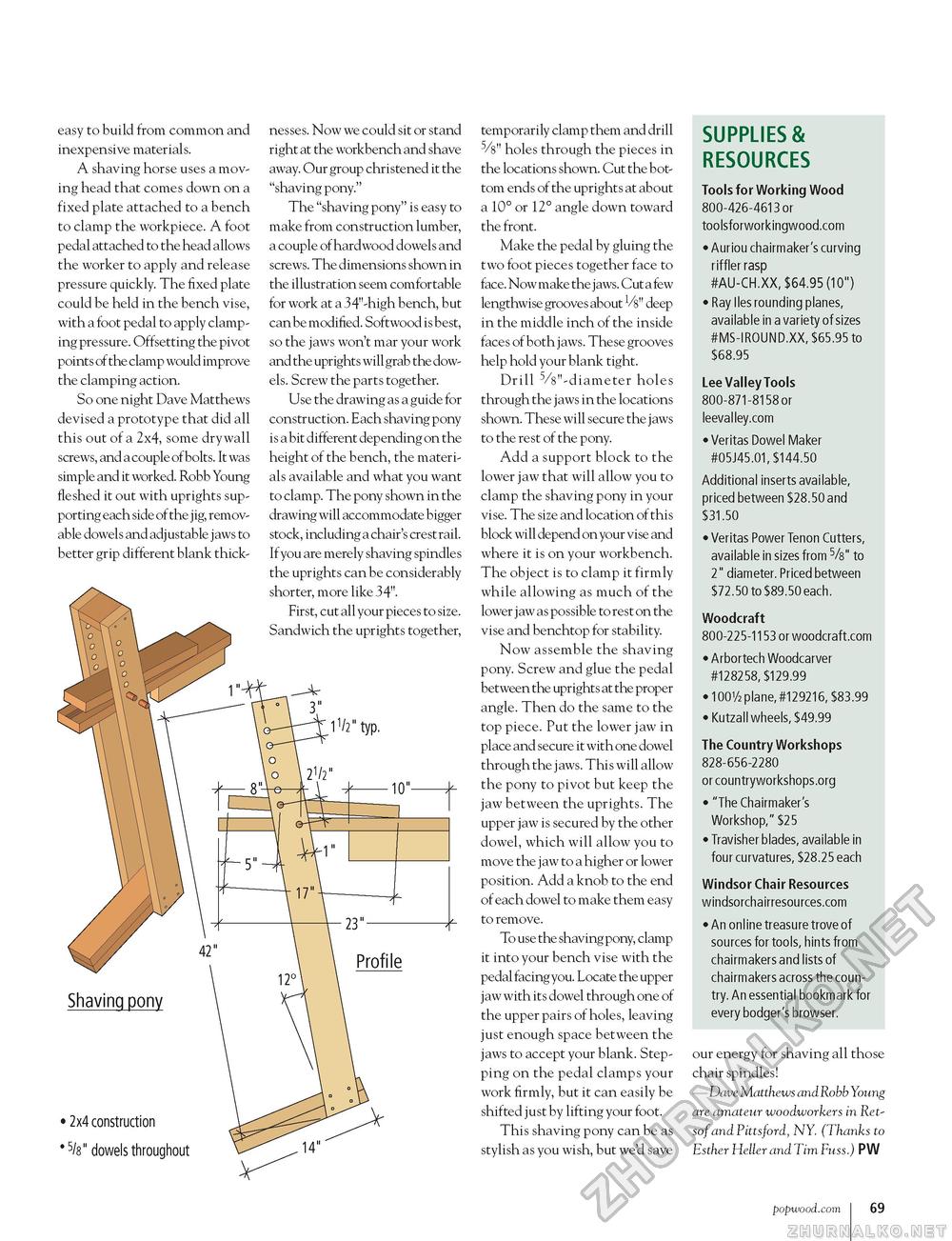

easy to build from common and inexpensive materials. A shaving horse uses a moving head that comes down on a fixed plate attached to a bench to clamp the workpiece. A foot pedal attached to the head allows the worker to apply and release pressure quickly. The fixed plate could be held in the bench vise, with a foot pedal to apply clamping pressure. Offsetting the pivot points of the clamp would improve the clamping action. So one night Dave Matthews devised a prototype that did all this out of a 2x4, some drywall screws, and a couple of bolts. It was simple and it worked. Robb Young fleshed it out with uprights supporting each side of the j ig, removable dowels and adjustable jaws to better grip different blank thick- o \\ \ o\\° \ y \ \0 I \ \ 0 ^A \ nesses. Now we could sit or stand right at the workbench and shave away. Our group christened it the "shaving pony." The "shaving pony" is easy to make from construction lumber, a couple of hardwood dowels and screws. The dimensions shown in the illustration seem comfortable for work at a 34"-high bench, but can be modified. Softwood is best, so the jaws won't mar your work and the uprights will grab the dowels. Screw the parts together. Use the drawing as a guide for construction. Each shaving pony is a bit different depending on the height of the bench, the materials available and what you want to clamp. The pony shown in the drawing will accommodate bigger stock, including a chair's crest rail. If you are merely shaving spindles the uprights can be considerably shorter, more like 34". First, cut all your pieces to size. Sandwich the uprights together, temporarily clamp them and drill holes through the pieces in the locations shown. Cut the bottom ends of the uprights at about a 10° or 12° angle down toward the front. Make the pedal by gluing the two foot pieces together face to face. Now make the jaws. Cut a few lengthwise grooves about V8" deep in the middle inch of the inside faces of both jaws. These grooves help hold your blank tight. Drill 5/8"-diameter holes through the jaws in the locations shown. These will secure the jaws to the rest of the pony. Add a support block to the lower jaw that will allow you to clamp the shaving pony in your vise. The size and location of this block will depend on your vise and where it is on your workbench. The object is to clamp it firmly while allowing as much of the lower jaw as possible to rest on the vise and benchtop for stability. Now assemble the shaving pony. Screw and glue the pedal between the uprights at the proper angle. Then do the same to the top piece. Put the lower jaw in place and secure it with one dowel through the jaws. This will allow the pony to pivot but keep the jaw between the uprights. The upper jaw is secured by the other dowel, which will allow you to move the j aw to a higher or lower position. Add a knob to the end of each dowel to make them easy to remove. To use the shaving pony, clamp it into your bench vise with the pedal facing you. Locate the upper jaw with its dowel through one of the upper pairs of holes, leaving just enough space between the jaws to accept your blank. Stepping on the pedal clamps your work firmly, but it can easily be shifted just by lifting your foot. This shaving pony can be as stylish as you wish, but we'd save SUPPLIES & RESOURCES Tools for Working Wood 800-426-4613 or toolsforworkingwood.com • Auriou chairmaker's curving riffler rasp #AU-CH.XX, $64.95 (10") • Ray Iles rounding planes, available in a variety of sizes #MS-IROUND.XX, $65.95 to $68.95 Lee Valley Tools 800-871-8158 or leevalley.com • Veritas Dowel Maker #05J45.01, $144.50 Additional inserts available, priced between $28.50 and $31.50 • Veritas Power Tenon Cutters, available in sizes from 5/k" to 2" diameter. Priced between $72.50 to $89.50 each. Woodcraft 800-225-1153 or woodcraft.com • Arbortech Woodcarver #128258, $129.99 • 100/ plane, #129216, $83.99 • Kutzall wheels, $49.99 The Country Workshops 828-656-2280 or countryworkshops.org • "The Chairmaker's Workshop," $25 • Travisher blades, available in four curvatures, $28.25 each Windsor Chair Resources windsorchairresources.com • An online treasure trove of sources for tools, hints from chairmakers and lists of chairmakers across the country. An essential bookmark for every bodger's browser. our energy for shaving all those chair spindles! —Dave Matthews and Robb Young are amateur woodworkers in Ret-sof and Pittsford, NY. (Thanks to Esther Heller and Tim Fuss.) PW popwood.com 69 |