Popular Woodworking 2005-06 № 148, страница 47

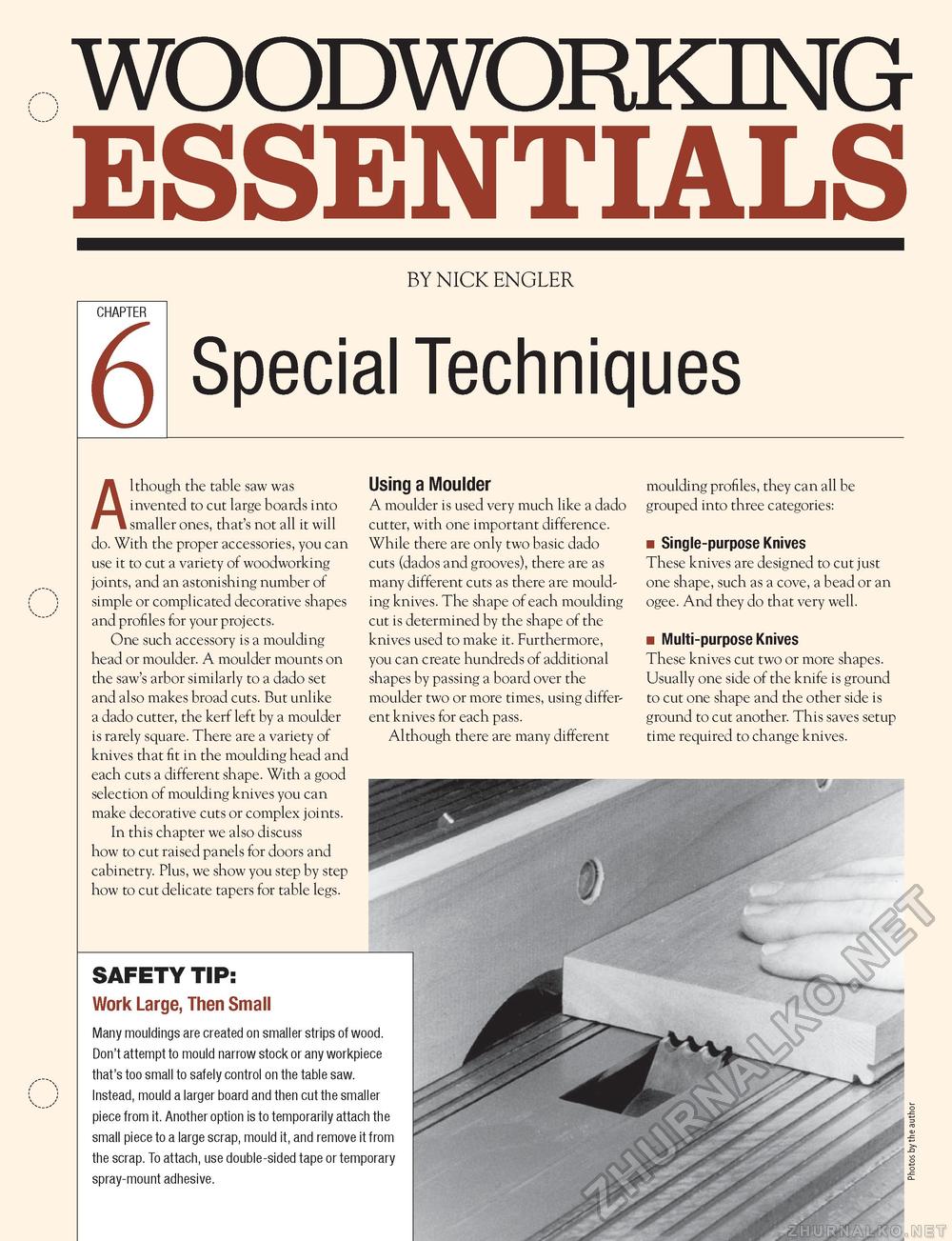

WOODWORKINGESSENTIALSBY NICK ENGLER CHAPTER 6 Special Techniques Although the table saw was invented to cut large boards into smaller ones, that's not all it will do. With the proper accessories, you can use it to cut a variety of woodworking joints, and an astonishing number of simple or complicated decorative shapes and profiles for your projects. One such accessory is a moulding head or moulder. A moulder mounts on the saw's arbor similarly to a dado set and also makes broad cuts. But unlike a dado cutter, the kerf left by a moulder is rarely square. There are a variety of knives that fit in the moulding head and each cuts a different shape. With a good selection of moulding knives you can make decorative cuts or complex joints. In this chapter we also discuss how to cut raised panels for doors and cabinetry. Plus, we show you step by step how to cut delicate tapers for table legs. Using a Moulder A moulder is used very much like a dado cutter, with one important difference. While there are only two basic dado cuts (dados and grooves), there are as many different cuts as there are moulding knives. The shape of each moulding cut is determined by the shape of the knives used to make it. Furthermore, you can create hundreds of additional shapes by passing a board over the moulder two or more times, using different knives for each pass. Although there are many different moulding profiles, they can all be grouped into three categories: ■ Single-purpose Knives These knives are designed to cut just one shape, such as a cove, a bead or an ogee. And they do that very well. ■ Multi-purpose Knives These knives cut two or more shapes. Usually one side of the knife is ground to cut one shape and the other side is ground to cut another. This saves setup time required to change knives. SAFETY TIP: Work Large, Then Small Many mouldings are created on smaller strips of wood. Don't attempt to mould narrow stock or any workpiece that's too small to safely control on the table saw. Instead, mould a larger board and then cut the smaller piece from it. Another option is to temporarily attach the small piece to a large scrap, mould it, and remove it from the scrap. To attach, use double-sided tape or temporary spray-mount adhesive. |