Popular Woodworking 2005-08 № 149, страница 50

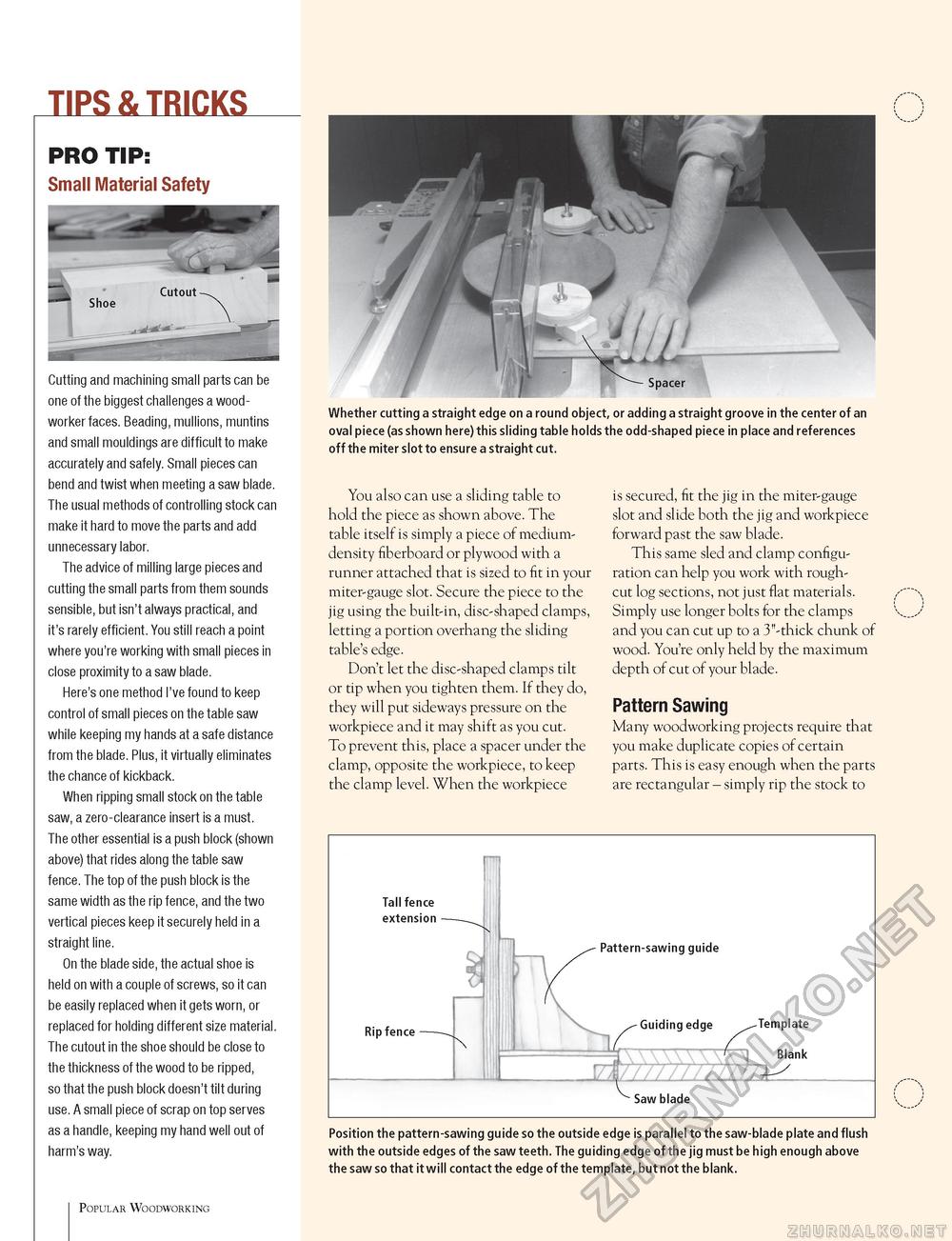

TIPS & TRICKS PRO TIP: Small Material Safety Cutting and machining small parts can be one of the biggest challenges a woodworker faces. Beading, mullions, muntins and small mouldings are difficult to make accurately and safely. Small pieces can bend and twist when meeting a saw blade. The usual methods of controlling stock can make it hard to move the parts and add unnecessary labor. The advice of milling large pieces and cutting the small parts from them sounds sensible, but isn't always practical, and it's rarely efficient. You still reach a point where you're working with small pieces in close proximity to a saw blade. Here's one method I've found to keep control of small pieces on the table saw while keeping my hands at a safe distance from the blade. Plus, it virtually eliminates the chance of kickback. When ripping small stock on the table saw, a zero-clearance insert is a must. The other essential is a push block (shown above) that rides along the table saw fence. The top of the push block is the same width as the rip fence, and the two vertical pieces keep it securely held in a straight line. On the blade side, the actual shoe is held on with a couple of screws, so it can be easily replaced when it gets worn, or replaced for holding different size material. The cutout in the shoe should be close to the thickness of the wood to be ripped, so that the push block doesn't tilt during use. A small piece of scrap on top serves as a handle, keeping my hand well out of harm's way. Spacer Whether cutting a straight edge on a round object, or adding a straight groove in the center of an oval piece (as shown here) this sliding table holds the odd-shaped piece in place and references off the miter slot to ensure a straight cut. You also can use a sliding table to hold the piece as shown above. The table itself is simply a piece of medium-density fiberboard or plywood with a runner attached that is sized to fit in your miter-gauge slot. Secure the piece to the jig using the built-in, disc-shaped clamps, letting a portion overhang the sliding table's edge. Don't let the disc-shaped clamps tilt or tip when you tighten them. If they do, they will put sideways pressure on the workpiece and it may shift as you cut. To prevent this, place a spacer under the clamp, opposite the workpiece, to keep the clamp level. When the workpiece is secured, fit the jig in the miter-gauge slot and slide both the jig and workpiece forward past the saw blade. This same sled and clamp configuration can help you work with rough-cut log sections, not just flat materials. Simply use longer bolts for the clamps and you can cut up to a 3"-thick chunk of wood. You're only held by the maximum depth of cut of your blade. Pattern Sawing Many woodworking projects require that you make duplicate copies of certain parts. This is easy enough when the parts are rectangular - simply rip the stock to Position the pattern-sawing guide so the outside edge is parallel to the saw-blade plate and flush with the outside edges of the saw teeth. The guiding edge of the jig must be high enough above the saw so that it will contact the edge of the template, but not the blank. Popular Woodworking |