Popular Woodworking 2006-02 № 153, страница 50

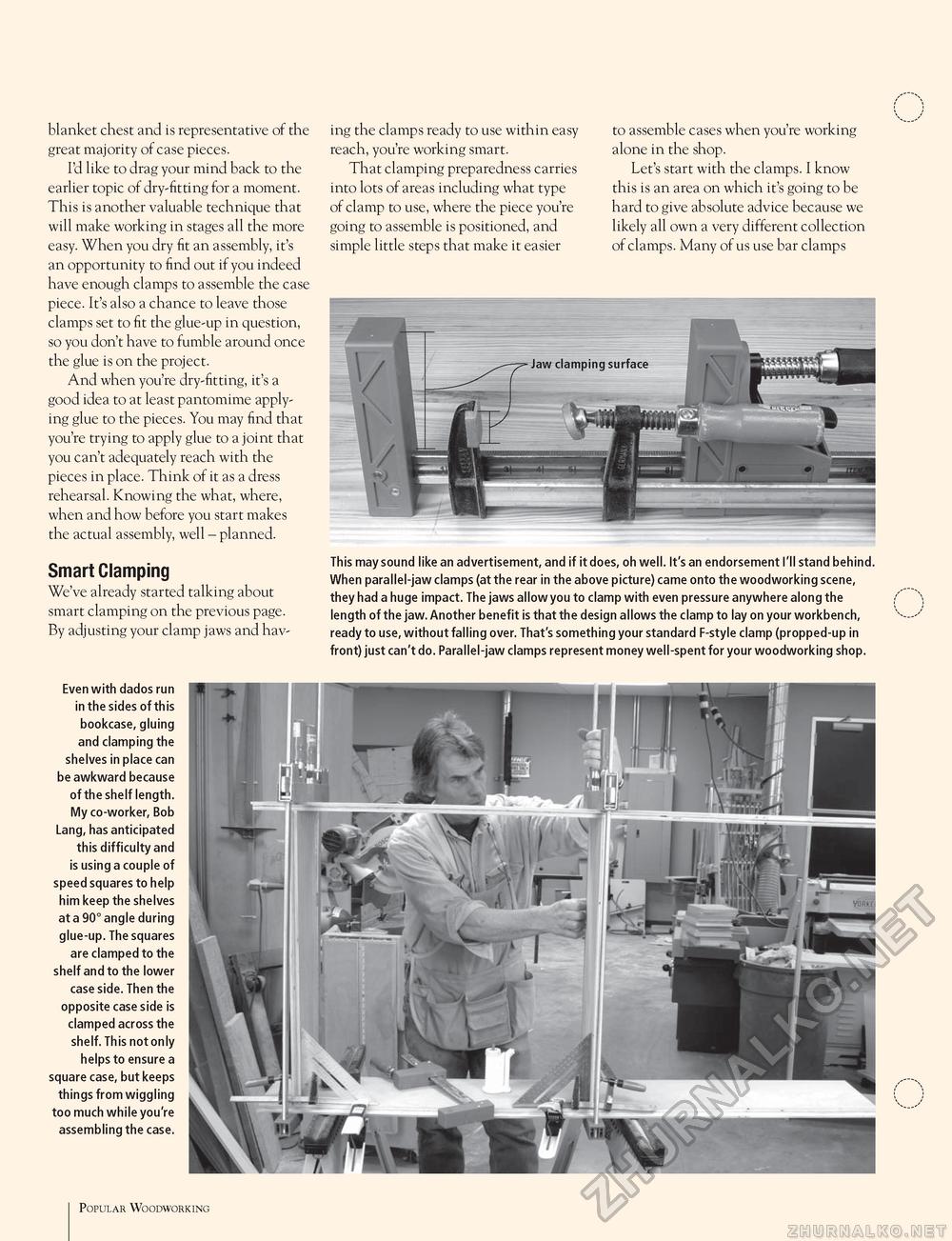

blanket chest and is representative of the great majority of case pieces. I'd like to drag your mind back to the earlier topic of dry-fitting for a moment. This is another valuable technique that will make working in stages all the more easy. When you dry fit an assembly, it's an opportunity to find out if you indeed have enough clamps to assemble the case piece. It's also a chance to leave those clamps set to fit the glue-up in question, so you don't have to fumble around once the glue is on the project. And when you're dry-fitting, it's a good idea to at least pantomime applying glue to the pieces. You may find that you're trying to apply glue to a joint that you can't adequately reach with the pieces in place. Think of it as a dress rehearsal. Knowing the what, where, when and how before you start makes the actual assembly, well - planned. Smart Clamping We've already started talking about smart clamping on the previous page. By adjusting your clamp jaws and hav- ing the clamps ready to use within easy reach, you're working smart. That clamping preparedness carries into lots of areas including what type of clamp to use, where the piece you're going to assemble is positioned, and simple little steps that make it easier to assemble cases when you're working alone in the shop. Let's start with the clamps. I know this is an area on which it's going to be hard to give absolute advice because we likely all own a very different collection of clamps. Many of us use bar clamps This may sound like an advertisement, and if it does, oh well. It's an endorsement I'll stand behind. When parallel-jaw clamps (at the rear in the above picture) came onto the woodworking scene, they had a huge impact. The jaws allow you to clamp with even pressure anywhere along the length of the jaw. Another benefit is that the design allows the clamp to lay on your workbench, ready to use, without falling over. That's something your standard F-style clamp (propped-up in front) just can't do. Parallel-jaw clamps represent money well-spent for your woodworking shop. Even with dados run in the sides of this bookcase, gluing and clamping the shelves in place can be awkward because of the shelf length. My co-worker, Bob Lang, has anticipated this difficulty and is using a couple of speed squares to help him keep the shelves at a 90° angle during glue-up. The squares are clamped to the shelf and to the lower case side. Then the opposite case side is clamped across the shelf. This not only helps to ensure a square case, but keeps things from wiggling too much while you're assembling the case. Popular Woodworking |