Popular Woodworking 2007-08 № 163, страница 11

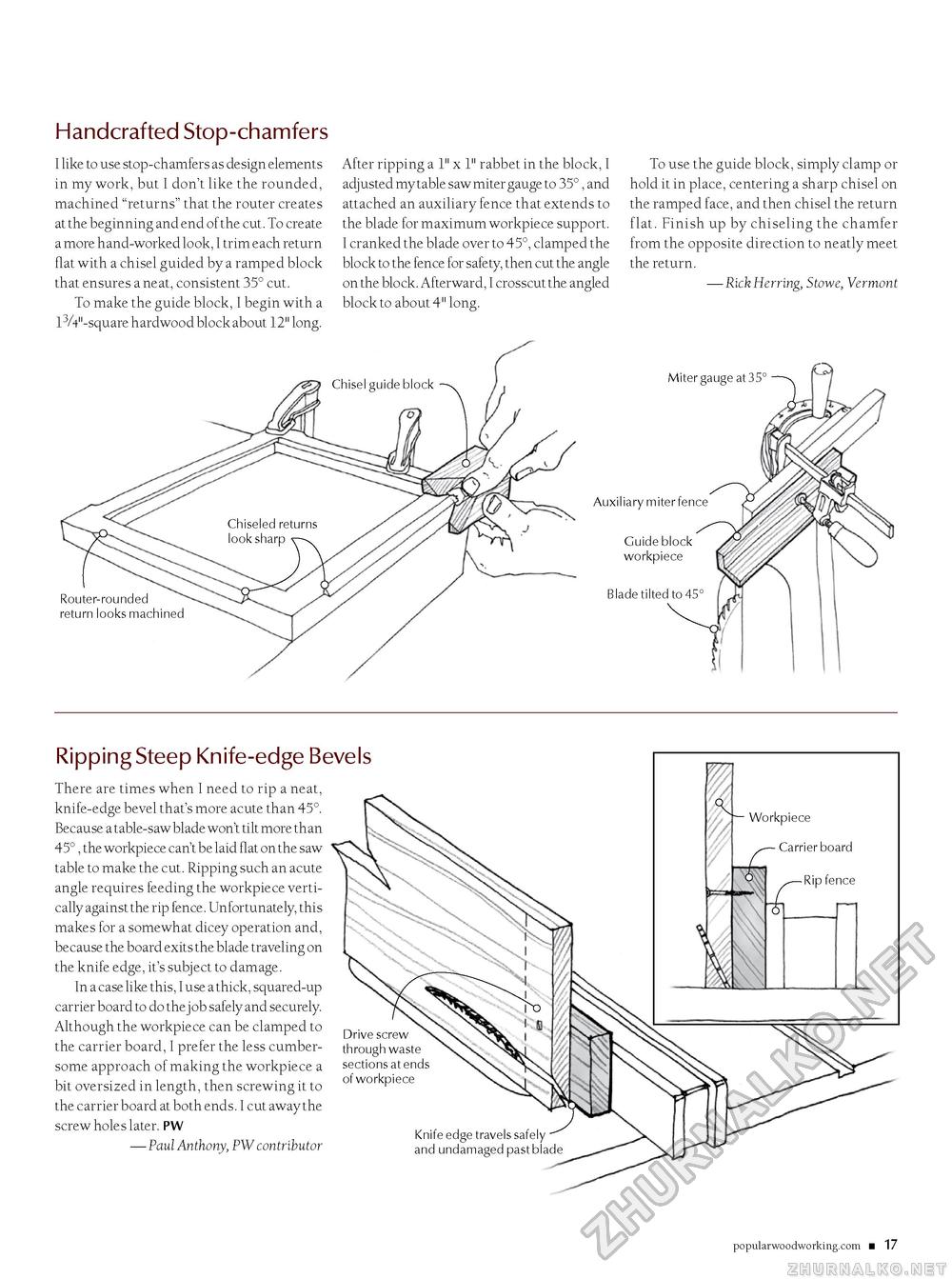

Handcrafted Stop-chamfers I like to use stop-chamfers as design elements in my work, but I don't like the rounded, machined "returns" that the router creates at the beginning and end of the cut. To create a more hand-worked look, I trim each return flat with a chisel guided by a ramped block that ensures a neat, consistent 35° cut. To make the guide block, I begin with a 13A"-square hardwood block about 12" long. After ripping a 1" x 1" rabbet in the block, I adjusted my table saw miter gauge to 35° , and attached an auxiliary fence that extends to the blade for maximum workpiece support. I cranked the blade over to 45°, clamped the block to the fence for safety, then cut the angle on the block. Afterward, I crosscut the angled block to about 4" long. To use the guide block, simply clamp or hold it in place, centering a sharp chisel on the ramped face, and then chisel the return flat. Finish up by chiseling the chamfer from the opposite direction to neatly meet the return. — Rick Herring, Stowe, Vermont Chiseled returns look sharp Router-rounded return looks machined Chisel guide block ■ K- Miter gauge at 35 Auxiliary miter fence Guide block workpiece Blade tilted to 45 Ripping Steep Knife-edge Bevels There are times when I need to rip a neat, knife-edge bevel that's more acute than 45°. Because a table-saw blade won't tilt more than 45° , the workpiece can't be laid flat on the saw table to make the cut. Ripping such an acute angle requires feeding the workpiece vertically against the rip fence. Unfortunately, this makes for a somewhat dicey operation and, because the board exits the blade traveling on the knife edge, it's subject to damage. In a case like this, I use a thick, squared-up carrier board to do the j ob safely and securely. Although the workpiece can be clamped to the carrier board, I prefer the less cumbersome approach of making the workpiece a bit oversized in length, then screwing it to the carrier board at both ends. I cut away the screw holes later. PW — Paul Anthony, PW contributor Drive screw through waste sections at ends of workpiece Knife edge travels safely and undamaged past blade Workpiece Carrier board -Rip fence popularwoodworking.com ■ 17 |