Popular Woodworking 2007-08 № 163, страница 12

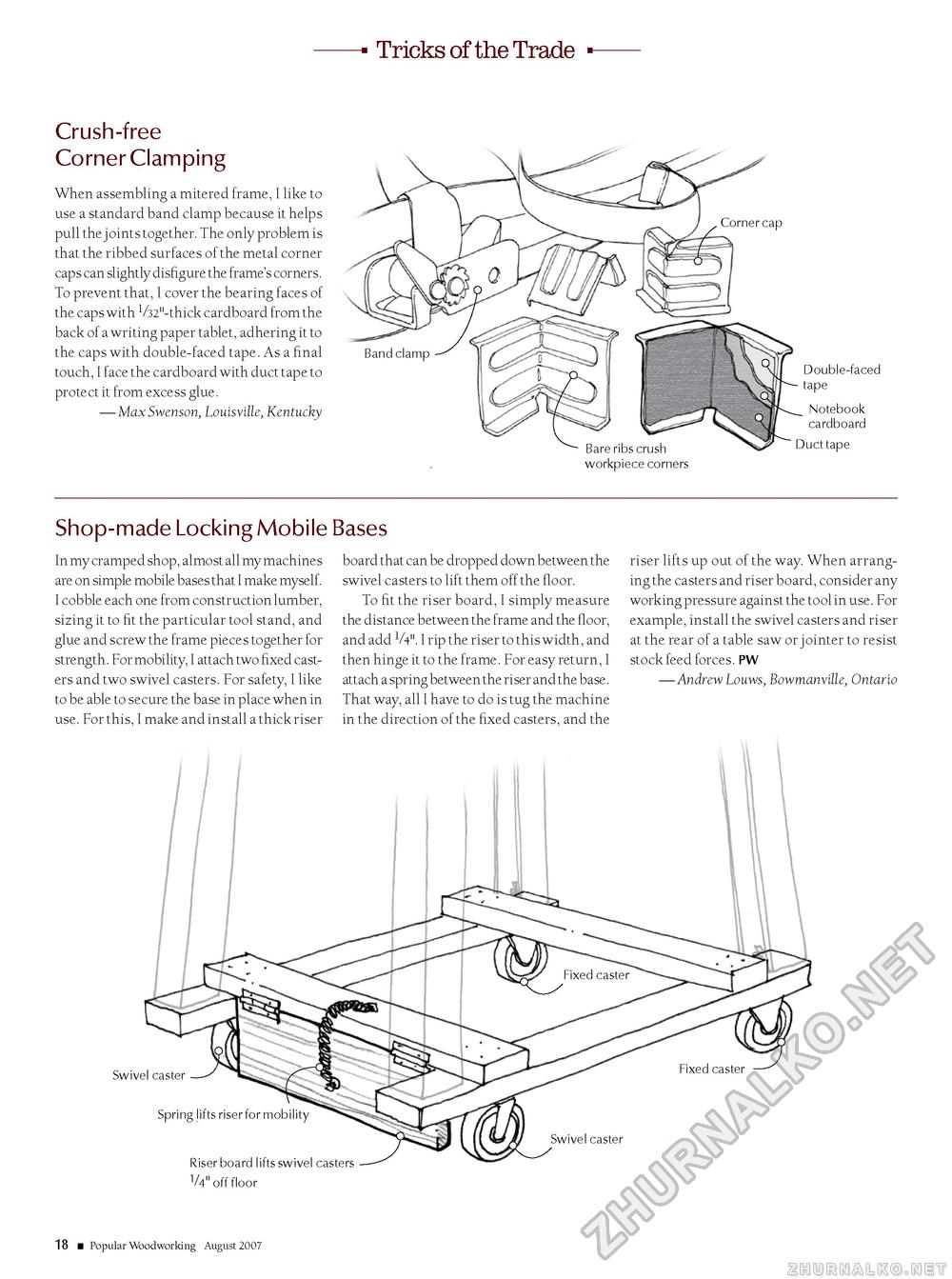

Tricks of the Trade Crush-free Corner Clamping When assembling a mitered frame, I like to use a standard band clamp because it helps pull the joints together. The only problem is that the ribbed surfaces of the metal corner caps can slightly disfigure the frame's corners. To prevent that, I cover the bearing faces of the caps with 1/32"-thick cardboard from the back of a writing paper tablet, adhering it to the caps with double-faced tape. As a final touch, I face the cardboard with duct tape to protect it from excess glue. — Max Swenson, Louisville, Kentucky Bare ribs crush workpiece corners Double-faced tape Notebook cardboard ' Duct tape Shop-made Locking Mobile Bases In my cramped shop, almost all my machines are on simple mobile bases that I make myself. I cobble each one from construction lumber, sizing it to fit the particular tool stand, and glue and screw the frame pieces together for strength. For mobility, I attach two fixed casters and two swivel casters. For safety, I like to be able to secure the base in place when in use. For this, I make and install a thick riser board that can be dropped down between the swivel casters to lift them off the floor. To fit the riser board, I simply measure the distance between the frame and the floor, and add V4". I rip the riser to this width, and then hinge it to the frame. For easy return, I attach a spring between the riser and the base. That way, all I have to do is tug the machine in the direction of the fixed casters, and the riser lifts up out of the way. When arranging the casters and riser board, consider any working pressure against the tool in use. For example, install the swivel casters and riser at the rear of a table saw or jointer to resist stock feed forces. pW —Andrew Louws, Bowmanville, Ontario Swivel caster Spring lifts riser for mobility Riser board lifts swivel casters V4" off floor 18 ■ Popular Woodworking August 2007 |