Popular Woodworking 2007-08 № 163, страница 68

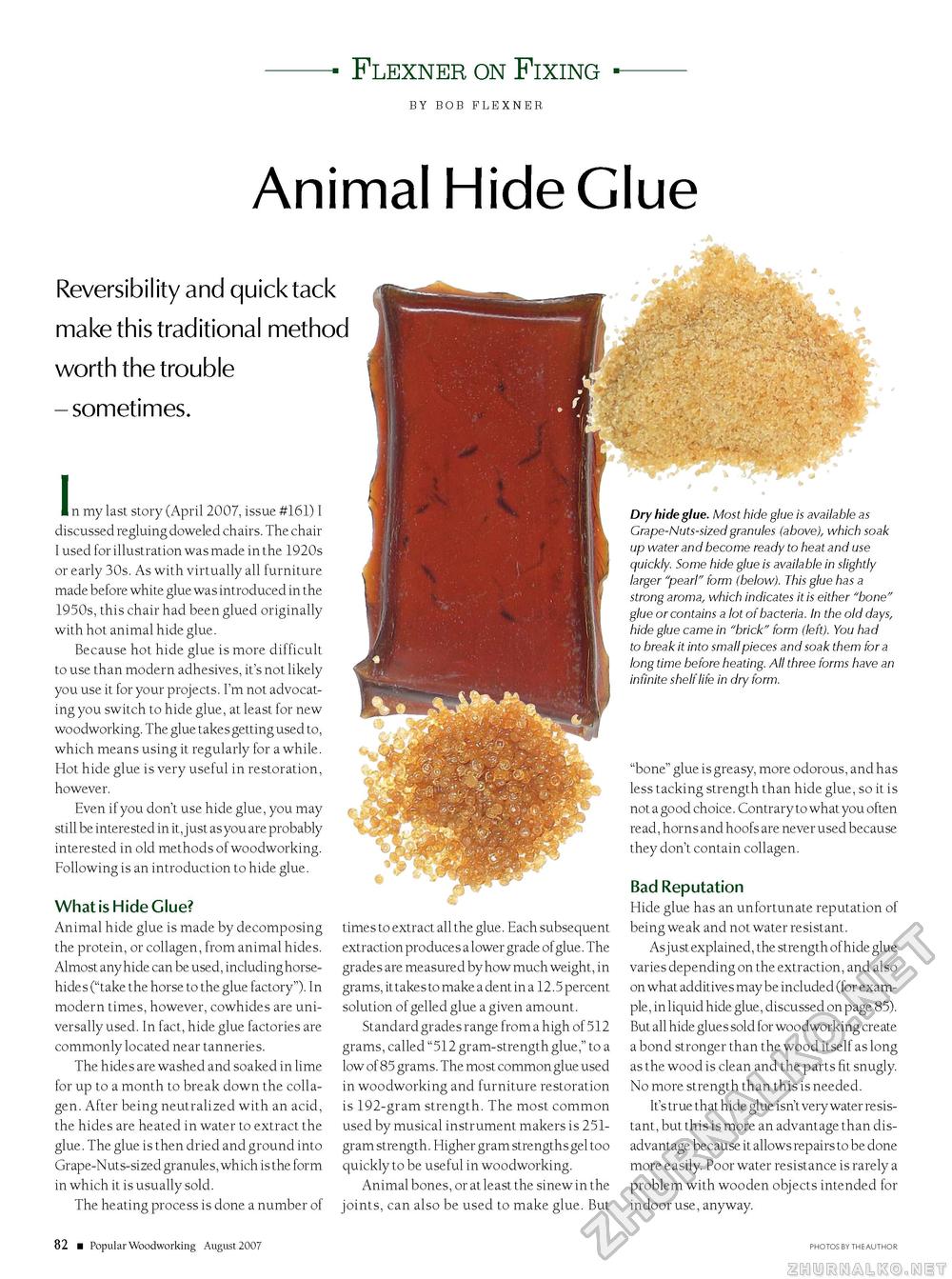

Flexner on Fixing by bob flexner Animal Hide Glue Reversibility and quick tack make this traditional method worth the trouble - sometimes. n my last story (April 2007, issue #161) I discussed regluing doweled chairs. The chair I used for illustration was made in the 1920s or early 30s. As with virtually all furniture made before white glue was introduced in the 1950s, this chair had been glued originally with hot animal hide glue. Because hot hide glue is more difficult to use than modern adhesives, it's not likely you use it for your projects. I'm not advocating you switch to hide glue, at least for new woodworking. The glue takes getting used to, which means using it regularly for a while. Hot hide glue is very useful in restoration, however. Even if you don't use hide glue, you may still be interested in it, just as you are probably interested in old methods of woodworking. Following is an introduction to hide glue. What is Hide Glue? Animal hide glue is made by decomposing the protein, or collagen, from animal hides. Almost any hide can be used, including horse-hides ("take the horse to the glue factory"). In modern times, however, cowhides are universally used. In fact, hide glue factories are commonly located near tanneries. The hides are washed and soaked in lime for up to a month to break down the collagen. After being neutralized with an acid, the hides are heated in water to extract the glue. The glue is then dried and ground into Grape-Nuts-sized granules, which is the form in which it is usually sold. The heating process is done a number of S3 a m&zt&t times to extract all the glue. Each subsequent extraction produces a lower grade of glue. The grades are measured by how much weight, in grams, it takes to make a dent in a 12.5 percent solution of gelled glue a given amount. Standard grades range from a high of 512 grams, called "512 gram-strength glue," to a low of 85 grams. The most common glue used in woodworking and furniture restoration is 192-gram strength. The most common used by musical instrument makers is 251-gram strength. Higher gram strengths gel too quickly to be useful in woodworking. Animal bones, or at least the sinew in the joints, can also be used to make glue. But Dry hide glue. Most hide glue is available as Grape-Nuts-sized granules (above), which soak up water and become ready to heat and use quickly. Some hide glue is available in slightly larger "pearl" form (below). This glue has a strong aroma, which indicates it is either "bone" glue or contains a lot of bacteria. In the old days, hide glue came in "brick" form (left). You had to break it into small pieces and soak them for a long time before heating. All three forms have an infinite shelf life in dry form. "bone" glue is greasy, more odorous, and has less tacking strength than hide glue, so it is not a good choice. Contrary to what you often read, horns and hoofs are never used because they don't contain collagen. Bad Reputation Hide glue has an unfortunate reputation of being weak and not water resistant. Asjust explained, the strength of hide glue varies depending on the extraction, and also on what additives may be included (for example, in liquid hide glue, discussed on page 85). But all hide glues sold for woodworking create a bond stronger than the wood itself as long as the wood is clean and the parts fit snugly. No more strength than this is needed. It's true that hide glue isn't very water resistant, but this is more an advantage than disadvantage because it allows repairs to be done more easily. Poor water resistance is rarely a problem with wooden objects intended for indoor use, anyway. 82 ■ Popular Woodworking August 2007 photos by theauthor |