Popular Woodworking 2007-10 № 164, страница 48

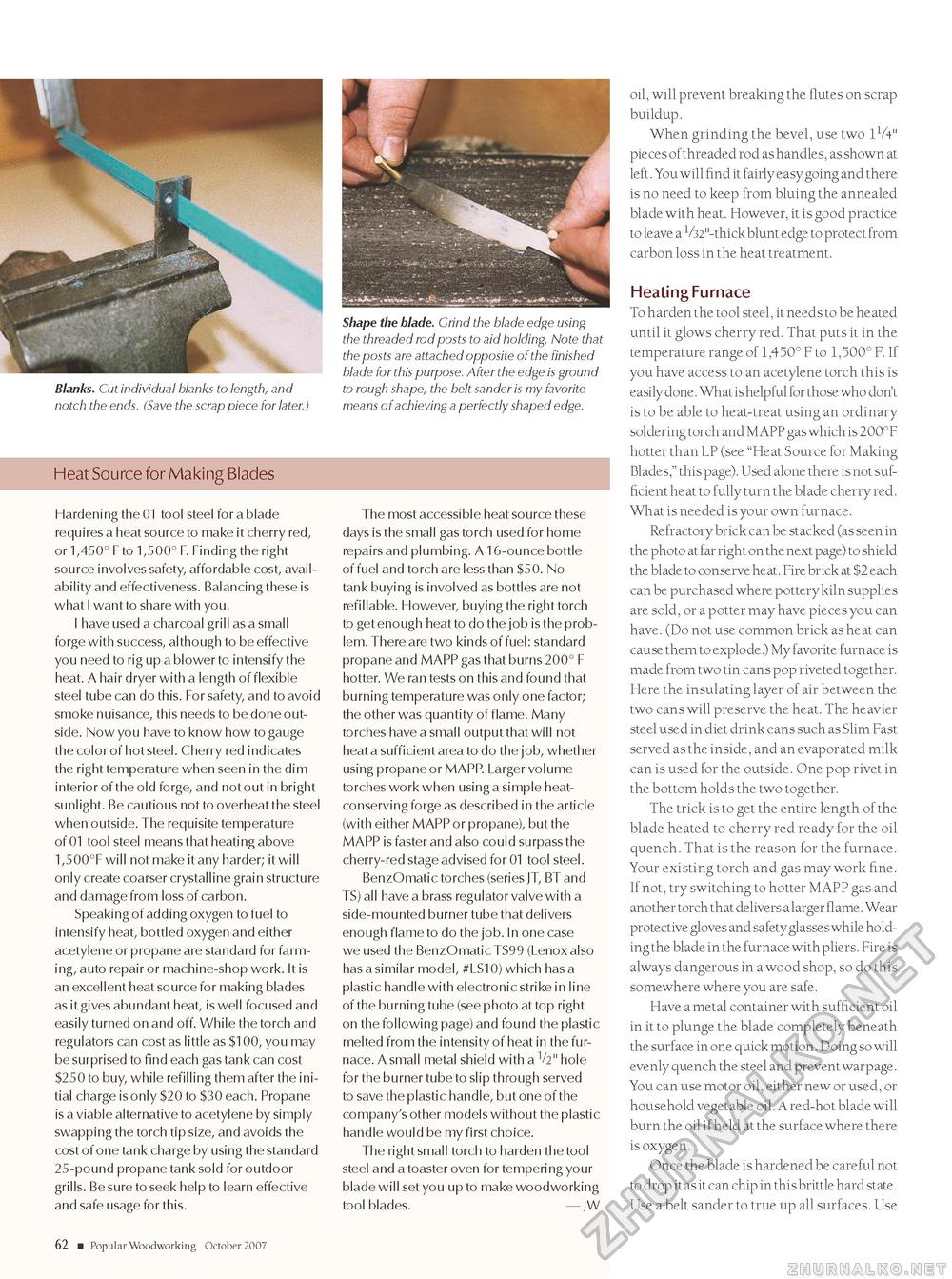

Blanks. Cut individual blanks to length, and notch the ends. (Save the scrap piece for later.) heat source for Making blades hardening the 01 tool steel for a blade requires a heat source to make it cherry red, or 1,450° F to 1,500° F. Finding the right source involves safety, affordable cost, availability and effectiveness. balancing these is what i want to share with you. i have used a charcoal grill as a small forge with success, although to be effective you need to rig up a blower to intensify the heat. A hair dryer with a length of flexible steel tube can do this. For safety, and to avoid smoke nuisance, this needs to be done outside. Now you have to know how to gauge the color of hot steel. Cherry red indicates the right temperature when seen in the dim interior of the old forge, and not out in bright sunlight. Be cautious not to overheat the steel when outside. The requisite temperature of 01 tool steel means that heating above 1,500°F will not make it any harder; it will only create coarser crystalline grain structure and damage from loss of carbon. Speaking of adding oxygen to fuel to intensify heat, bottled oxygen and either acetylene or propane are standard for farming, auto repair or machine-shop work. It is an excellent heat source for making blades as it gives abundant heat, is well focused and easily turned on and off. While the torch and regulators can cost as little as $100, you may be surprised to find each gas tank can cost $250 to buy, while refilling them after the initial charge is only $20 to $30 each. Propane is a viable alternative to acetylene by simply swapping the torch tip size, and avoids the cost of one tank charge by using the standard 25-pound propane tank sold for outdoor grills. Be sure to seek help to learn effective and safe usage for this. Shape the blade. Grind the blade edge using the threaded rod posts to aid holding. Note that the posts are attached opposite of the finished blade for this purpose. After the edge is ground to rough shape, the belt sander is my favorite means of achieving a perfectly shaped edge. The most accessible heat source these days is the small gas torch used for home repairs and plumbing. A 16-ounce bottle of fuel and torch are less than $50. No tank buying is involved as bottles are not refillable. However, buying the right torch to get enough heat to do the job is the problem. There are two kinds of fuel: standard propane and MAPP gas that burns 200° F hotter. We ran tests on this and found that burning temperature was only one factor; the other was quantity of flame. Many torches have a small output that will not heat a sufficient area to do the job, whether using propane or MAPP. Larger volume torches work when using a simple heat-conserving forge as described in the article (with either MAPP or propane), but the MAPP is faster and also could surpass the cherry-red stage advised for 01 tool steel. BenzOmatic torches (series JT, BT and TS) all have a brass regulator valve with a side-mounted burner tube that delivers enough flame to do the job. In one case we used the BenzOmatic TS99 (Lenox also has a similar model, #LS10) which has a plastic handle with electronic strike in line of the burning tube (see photo at top right on the following page) and found the plastic melted from the intensity of heat in the furnace. A small metal shield with a 1/2" hole for the burner tube to slip through served to save the plastic handle, but one of the company's other models without the plastic handle would be my first choice. The right small torch to harden the tool steel and a toaster oven for tempering your blade will set you up to make woodworking tool blades. — JW oil, will prevent breaking the flutes on scrap buildup. When grinding the bevel, use two 11/4" pieces of threaded rod as handles, as shown at left. You will find it fairly easy going and there is no need to keep from bluing the annealed blade with heat. However, it is good practice to leave a 1/32"-thick blunt edge to protect from carbon loss in the heat treatment. Heating Furnace To harden the tool steel, it needs to be heated until it glows cherry red. That puts it in the temperature range of 1,450° F to 1,500° F. If you have access to an acetylene torch this is easily done. What is helpful for those who don't is to be able to heat-treat using an ordinary soldering torch and MAPP gas which is 200°F hotter than LP (see "Heat Source for Making Blades," this page). Used alone there is not sufficient he at to fully turn the blade cherry red. What is needed is your own furnace. Refractory brick can be stacked (as seen in the photo at far right on the next page) to shield the blade to conserve heat. Fire brick at $2 each can be purchased where pottery kiln supplies are sold, or a potter may have pieces you can have. (Do not use common brick as heat can cause them to explode.) My favorite furnace is made from two tin cans pop riveted together. Here the insulating layer of air between the two cans will preserve the heat. The heavier steel used in diet drink cans such as Slim Fast served as the inside, and an evaporated milk can is used for the outside. One pop rivet in the bottom holds the two together. The trick is to get the entire length of the blade heated to cherry red ready for the oil quench. That is the reason for the furnace. Your existing torch and gas may work fine. If not, try switching to hotter MAPP gas and another torch that delivers a larger flame. Wear protective gloves and safety glasses while holding the blade in the furnace with pliers. Fire is always dangerous in a wood shop, so do this somewhere where you are safe. Have a metal container with sufficient oil in it to plunge the blade completely beneath the surface in one quick motion. Doing so will evenly quench the steel and prevent warpage. You can use motor oil, either new or used, or household vegetable oil. A red-hot blade will burn the oil if held at the surface where there is oxygen. Once the blade is hardened be careful not to drop it as it can chip in this brittle hard state. Use a belt sander to true up all surfaces. Use 62 ■ Popular Woodworking October 2007 |