Popular Woodworking 2007-10 № 164, страница 51

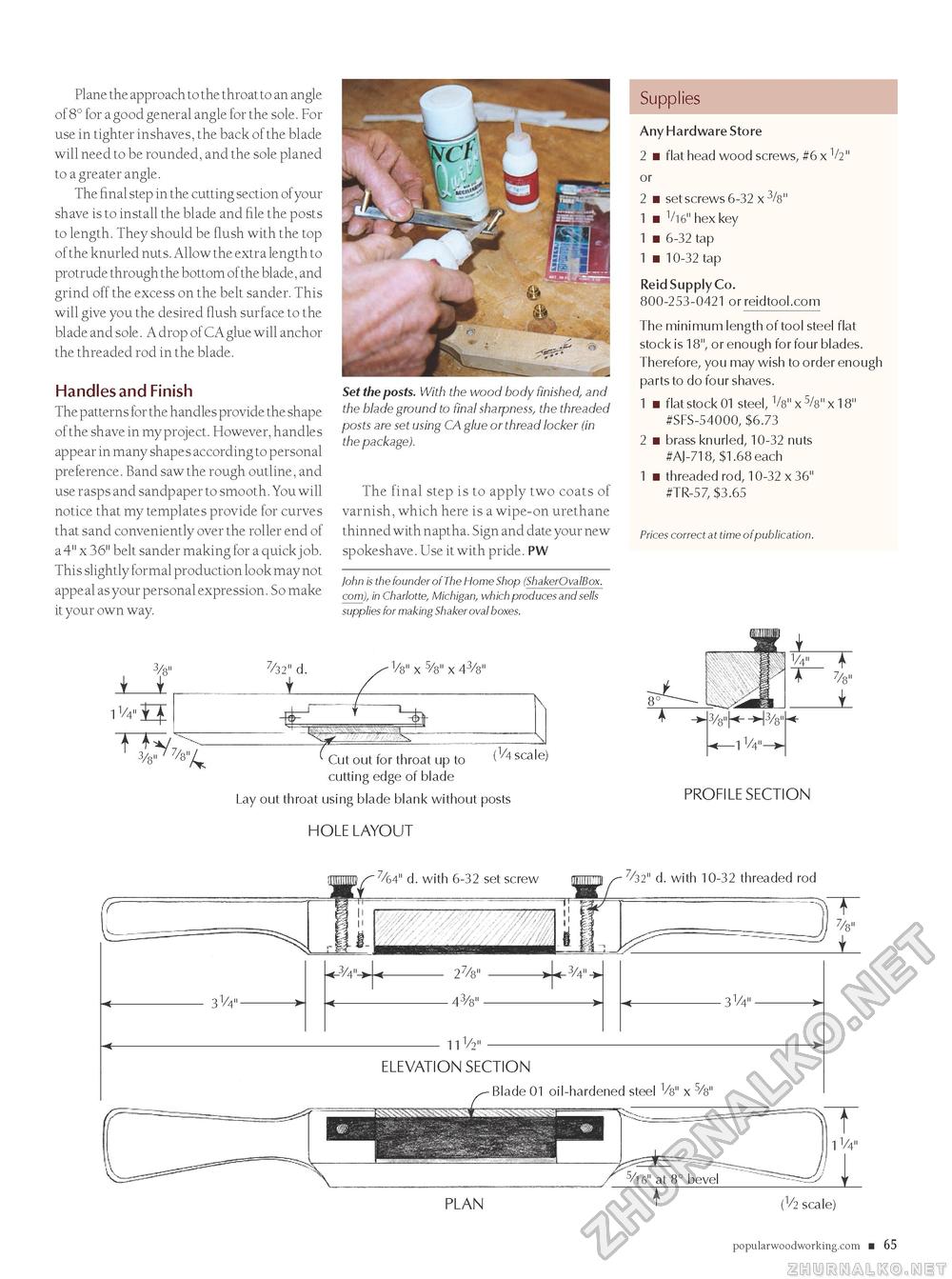

Plane the approach to the throat to an angle of 8° for a good general angle for the sole. For use in tighter inshaves, the back of the blade will need to be rounded, and the sole planed to a greater angle. The final step in the cutting section ot your shave is to install the blade and file the posts to length. They should be flush with the top ot the knurled nuts. Allow the extra length to protrude through the bottom ot the blade, and grind ott the excess on the belt sander. This will give you the desired flush surface to the blade and sole. A drop ot CA glue will anchor the threaded rod in the blade. Handles and Finish The patterns tor the handles provide the shape ot the shave in my project. However, handles appear in many shapes according to personal preference. Band saw the rough outline, and use rasps and sandpaper to smooth. You will notice that my templates provide tor curves that sand conveniently over the roller end ot a4" x36" belt sander making tor a quickjob. This slightly tormal production look may not appeal as your personal expression. So make it your own way. Supplies Set the posts. With the wood body finished, and the blade ground to final sharpness, the threaded posts are set using CA glue or thread locker (in the package). The tinal step is to apply two coats ot varnish, which here is a wipe-on urethane thinned with naptha. Sign and date your new spokeshave. Use it with pride. PW lohn is the founder of The Home Shop (ShakerOvalBox. com), in Charlotte, Michigan, which produces and sells supplies for making Shaker oval boxes. Any Hardware Store 2 ■ flat head wood screws, #6 x 1/2" or 2 ■ set screws 6-32 x 3/8" 1 ■ 1/16" hex key 1 ■ 6-32 tap 1 ■ 10-32 tap ReidSupplyCo. 800-253-0421 orreidtool.com The minimum length of tool steel flat stock is 18", or enough for four blades. Therefore, you may wish to order enough parts to do four shaves. 1 ■ flat stock 01 steel, Vs" x 5/8" x 18" #SFS-54000, $6.73 2 ■ brass knurled, 10-32 nuts #AJ-718, $1.68 each 1 ■ threaded rod, 10-32 x 36" #TR-57, $3.65 Prices correct at time of publication. 1/8" X S/8" X 43/8" Cut out for throat up to cutting edge of blade Lay out throat using blade blank without posts (1/4 scale)

profile section hole layout (T tc 7/64" d. with 6-32 set screw ■ 7/32" d. with 10-32 threaded rod _P TT S-3/4"-l 3V4" 27/8" <-3/4" -3V4" 1 1 1/2" elevation section Blade 01 oil-hardened steel Vs" x 5/s" T 11/4" 5A 6" at 8° bevel plan I (1/2 scale) popularwoodworking.com ■ 65 CIRCLE #152 ON FREE INFORMATION CARD. |