Popular Woodworking 2007-10 № 164, страница 50

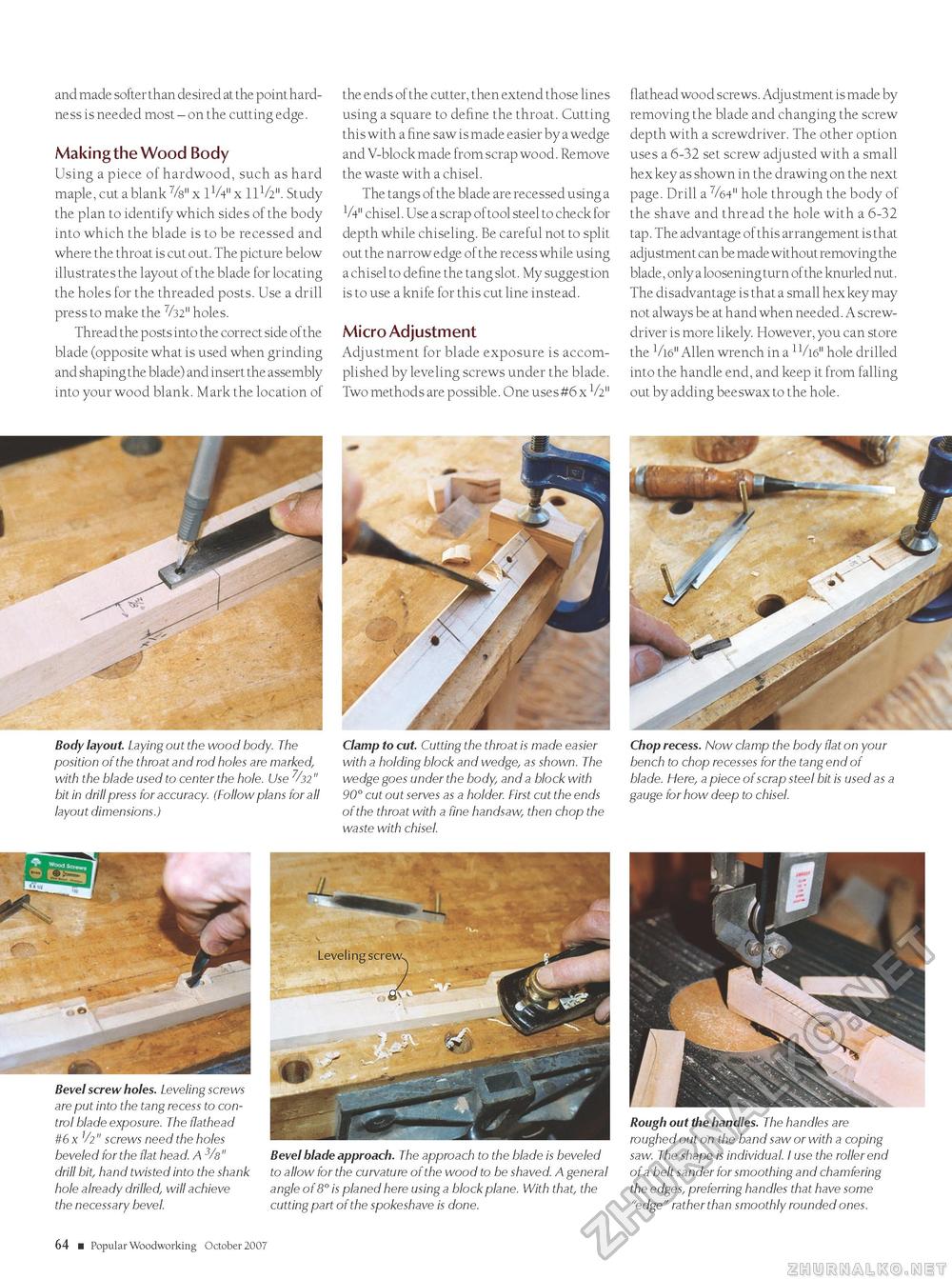

and made softer than desired at the point hardness is needed most - on the cutting edge. Making the Wood Body Using a piece of hardwood, such as hard maple, cut a blank 7/s" x 1V4" x 11V2". Study the plan to identify which sides of the body into which the blade is to be recessed and where the throat is cut out. The picture below illustrates the layout of the blade for locating the holes for the threaded posts. Use a drill press to make the 7/32" holes. Thread the posts into the correct side of the blade (opposite what is used when grinding and shaping the blade) and insert the assembly into your wood blank. Mark the location of the ends of the cutter, then extend those lines using a square to define the throat. Cutting this with a fine saw is made easier by a wedge and V-block made from scrap wood. Remove the waste with a chisel. The tangs of the blade are recessed using a V4" chisel. Use a scrap of tool steel to check for depth while chiseling. Be careful not to split out the narrow edge of the recess while using a chisel to define the tang slot. My suggestion is to use a knife for this cut line instead. Micro Adjustment Adjustment for blade exposure is accomplished by leveling screws under the blade. Two methods are possible. One uses #6 x 1/2" flathead wood screws. Adjustment is made by removing the blade and changing the screw depth with a screwdriver. The other option uses a 6-32 set screw adjusted with a small hex key as shown in the drawing on the next page. Drill a 7/64" hole through the body of the shave and thread the hole with a 6-32 tap. The advantage of this arrangement is that adjustment can be made without removing the blade, only a loosening turn of the knurled nut. The disadvantage is that a small hex key may not always be at hand when needed. A screwdriver is more likely. However, you can store the 1/16" Allen wrench in a 11/16" hole drilled into the handle end, and keep it from falling out by adding beeswax to the hole. Body layout. Laying out the wood body. The position of the throat and rod holes are marked, with the blade used to center the hole. Use 732" bit in drill press for accuracy. (Follow plans for all layout dimensions.) Clamp to cut. Cutting the throat is made easier with a holding block and wedge, as shown. The wedge goes under the body, and a block with 90° cut out serves as a holder. First cut the ends of the throat with a fine handsaw, then chop the waste with chisel. Chop recess. Now clamp the body flat on your bench to chop recesses for the tang end of blade. Here, a piece of scrap steel bit is used as a gauge for how deep to chisel. Bevel screw holes. Leveling screws are put into the tang recess to control blade exposure. The flathead #6 x V2" screws need the holes beveled for the flat head. A 3/a" drill bit, hand twisted into the shank hole already drilled, will achieve the necessary bevel. Bevel blade approach. The approach to the blade is beveled to allow for the curvature of the wood to be shaved. A general angle of 8° is planed here using a block plane. With that, the cutting part of the spokeshave is done. Rough out the handles. The handles are roughed out on the band saw or with a coping saw. The shape is individual. I use the roller end of a belt sander for smoothing and chamfering the edges, preferring handles that have some "edge" rather than smoothly rounded ones. 64 ■ Popular Woodworking October 2007 |