Popular Woodworking 2007-10 № 164, страница 49

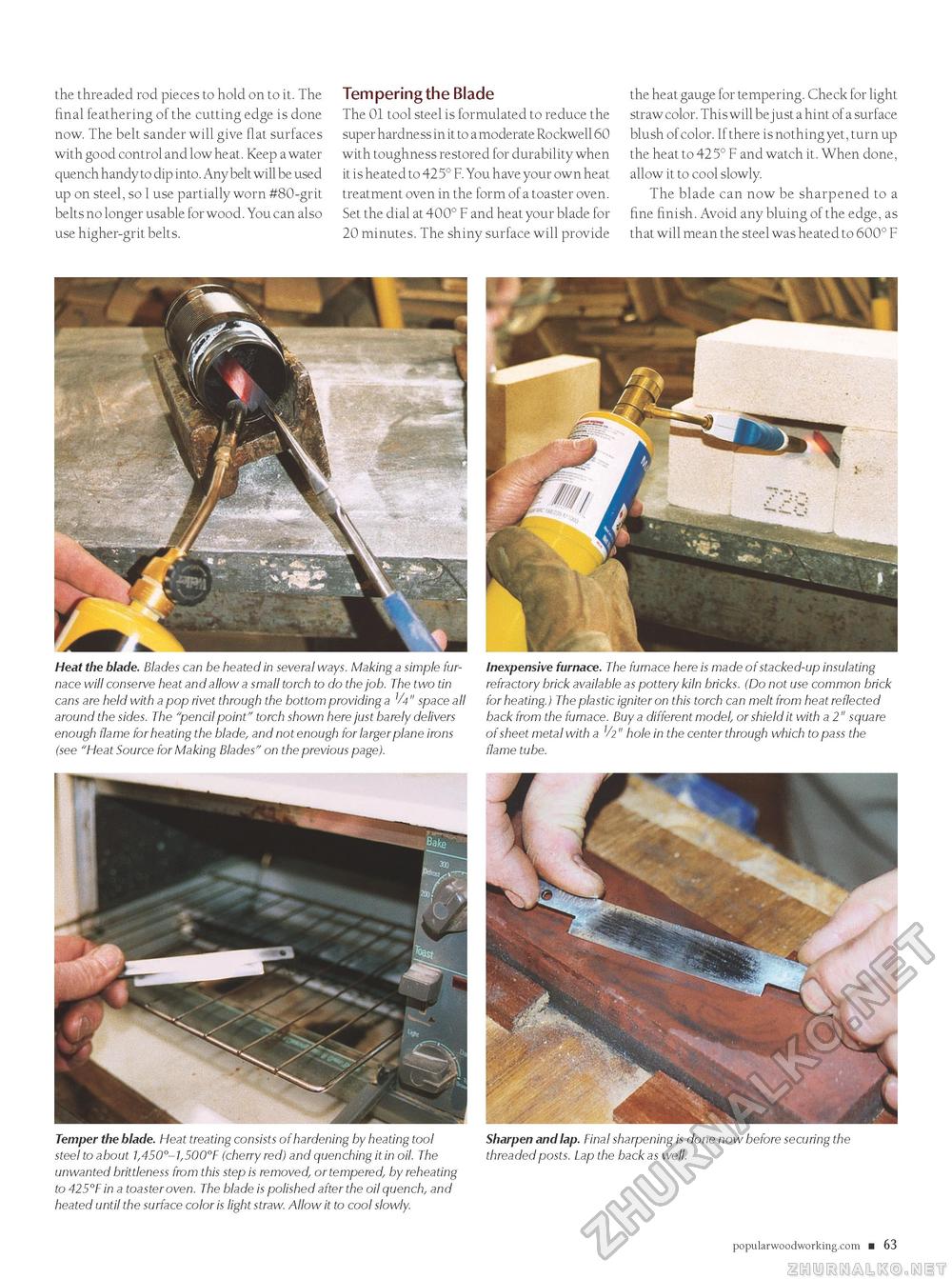

the threaded rod pieces to hold on to it. The final feathering of the cutting edge is done now. The belt sander will give flat surfaces with good control and low heat. Keep a water quench handy to dip into. Any belt will be used up on steel, so I use partially worn #80-grit belts no longer usable for wood. You can also use higher-grit belts. Tempering the Blade The 01 tool steel is formulated to reduce the super hardness in it to a moderate Rockwell 60 with toughness restored for durability when it is heated to 425° F. You have your own heat treatment oven in the form of a toaster oven. Set the dial at 400° F and heat your blade for 20 minutes. The shiny surface will provide the heat gauge for tempering. Check for light straw color. This will be just a hint of a surface blush of color. If there is nothing yet, turn up the heat to 425° F and watch it. When done, allow it to cool slowly. The blade can now be sharpened to a fine finish. Avoid any bluing of the edge, as that will mean the steel was heated to 600° F Heat the blade. Blades can be heated in several ways. Making a simple furnace will conserve heat and allow a small torch to do the job. The two tin cans are held with a pop rivet through the bottom providing a V4" space all around the sides. The "pencil point" torch shown here just barely delivers enough flame for heating the blade, and not enough for larger plane irons (see "Heat Source for Making Blades" on the previous page). Inexpensive furnace. The furnace here is made of stacked-up insulating refractory brick available as pottery kiln bricks. (Do not use common brick for heating.) The plastic igniter on this torch can melt from heat reflected back from the furnace. Buy a different model, or shield it with a 2" square of sheet metal with a V2" hole in the center through which to pass the flame tube. Temper the blade. Heat treating consists of hardening by heating tool steel to about 1,450°-1,500°F (cherry red) and quenching it in oil. The unwanted brittleness from this step is removed, or tempered, by reheating to 425°F in a toaster oven. The blade is polished after the oil quench, and heated until the surface color is light straw. Allow it to cool slowly. Sharpen and lap. Final sharpening is done now before securing the threaded posts. Lap the back as well. popularwoodworking.com ■ 63 CIRCLE #152 ON FREE INFORMATION CARD. |