Popular Woodworking 2007-11 № 165, страница 67

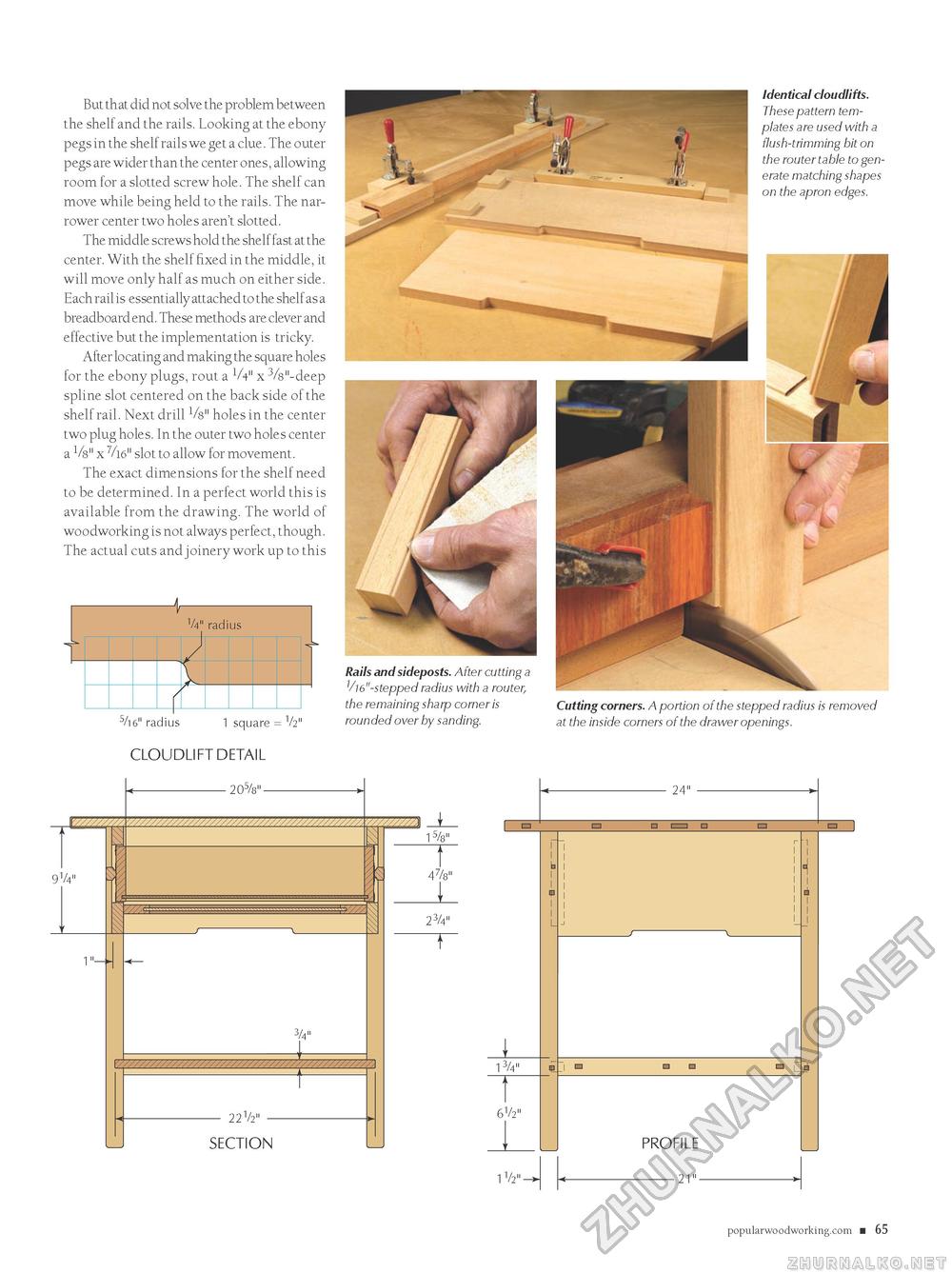

But that did not solve the problem between the shelf and the rails. Looking at the ebony pegs in the shelf rails we get a clue. The outer pegs are wider than the center ones, allowing room for a slotted screw hole. The shelf can move while being held to the rails. The narrower center two holes aren't slotted. The middle screws hold the shelf fast at the center. With the shelf fixed in the middle, it will move only half as much on either side. Each rail is essentially attached to the shelf as a breadboard end. These methods are clever and effective but the implementation is tricky. After locating and making the square holes for the ebony plugs, rout a V4" x 3/s"-deep spline slot centered on the back side of the shelf rail. Next drill Vs" holes in the center two plug holes. In the outer two holes center a Vs" x V16" slot to allow for movement. The exact dimensions for the shelf need to be determined. In a perfect world this is available from the drawing. The world of woodworking is not always perfect, though. The actual cuts and j oinery work up to this Identical cloudlifts. These pattern templates are used with a flush-trimming bit on the router table to generate matching shapes on the apron edges. 5/i6" radius 1 square = V2" CLOUDLIFT DETAIL Rails andsideposts. After cutting a V16"-steppedradius with a router, the remaining sharp corner is rounded over by sanding. Cutting corners. A portion of the stepped radius is removed at the inside corners of the drawer openings. 24" 1 1 3/4" T 6V2" 1V2" PROFILE 21" popularwoodworking.com ■ 65 |