Popular Woodworking 2007-12 № 166, страница 43

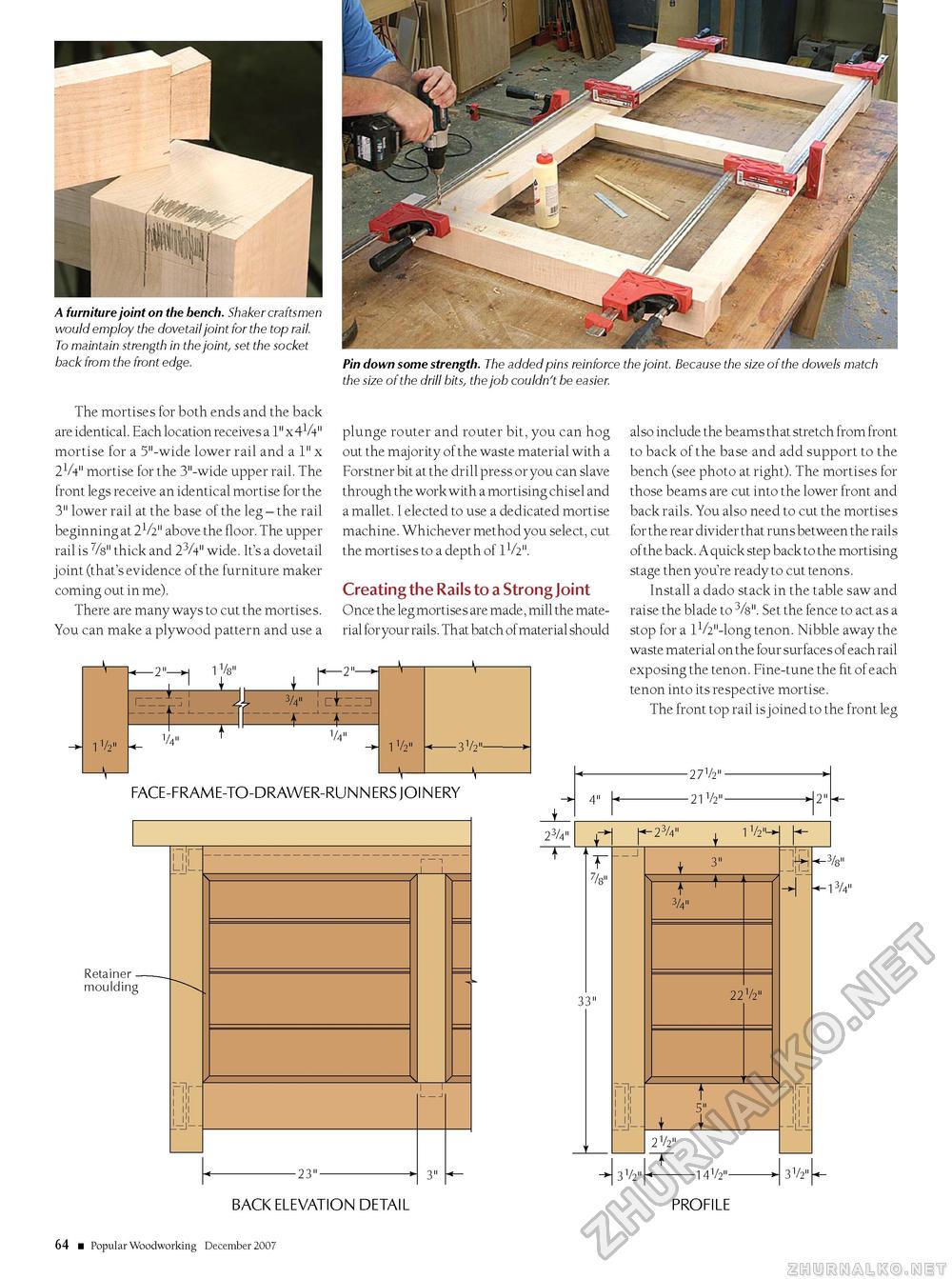

A furniture joint on the bench. Shaker craftsmen would employ the dovetail joint for the top rail. To maintain strength in the joint, set the socket back from the front edge. The mortises for both ends and the back are identical. Each location receives a 1" x 41/4" mortise for a 5"-wide lower rail and a 1" x 2V4" mortise for the 3"-wide upper rail. The front legs receive an identical mortise for the 3" lower rail at the base of the leg - the rail beginning at 21/2" above the floor. The upper rail is %" thick and 23A" wide. It's a dovetail joint (that's evidence of the furniture maker coming out in me). There are many ways to cut the mortises. You can make a plywood pattern and use a Pin down some strength. The added pins reinforce the joint. Because the size of the dowels match the size of the drill bits, the job couldn't be easier. plunge router and router bit, you can hog out the majority of the waste material with a Forstner bit at the drill press or you can slave through the work with a mortising chisel and a mallet. I elected to use a dedicated mortise machine. Whichever method you select, cut the mortises to a depth of 1V2". Creating the Rails to a Strong Joint Once the leg mortises are made, mill the material for your rails. That batch of material should also include the beams that stretch from front to back of the base and add support to the bench (see photo at right). The mortises for those beams are cut into the lower front and back rails. You also need to cut the mortises for the rear divider that runs between the rails of the back. A quick step back to the mortising stage then you're ready to cut tenons. Install a dado stack in the table saw and raise the blade to 3/8". Set the fence to act as a stop for a 11/2"-long tenon. Nibble away the waste material on the four surfaces of each rail back elevation detail profile 64 ■ Popular Woodworking December 2007 |