Popular Woodworking 2008-08 № 170, страница 27

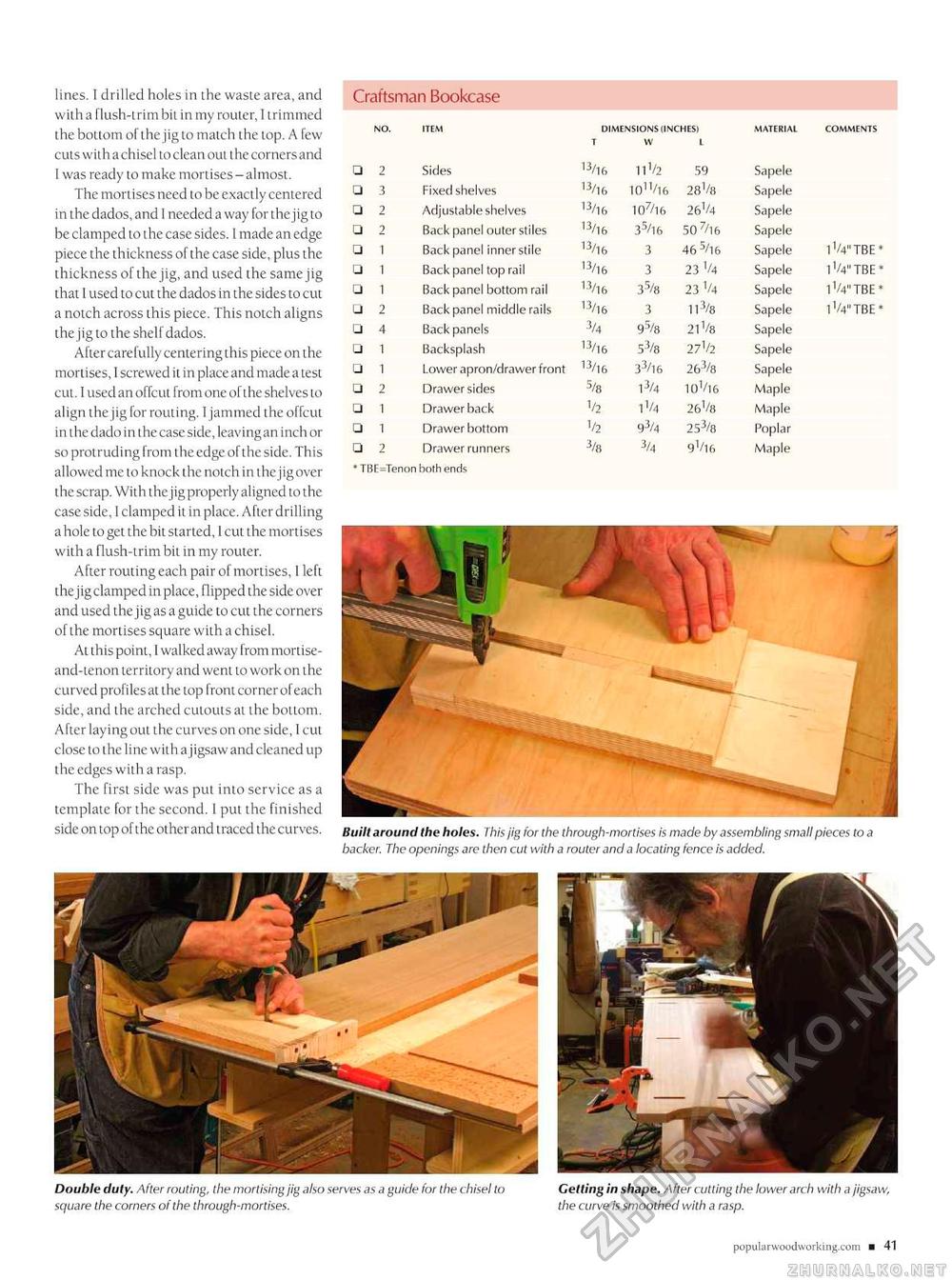

lines. I drilled holes in the waste area, and with a flush-trim bit in my router, I trimmed the bottom of the jig to match the top. A few cuts with a chisel to clean out the corners and 1 was ready to make mortises-almost. The mortises need to be exactly centered in the dados,and I neededa way forthejigto be clamped to the case sides. 1 made an edge piece the thickness of the case side, plus the thickness of the jig, and used the same jig that I used to cut the dados in the sides to cut a notch across this piece. This notch aligns the jig to the shelf dados. After carefully centering this piece on the mortises, I screwed it in place and made a test cut. I used an offcut from one of the shelves to align thejig for routing. I jammed the offcut in the dado in the case side, leaving an inch or so protruding from the edge of the side. This allowed me to knock the notch in thejig over the scrap. With thejig properly al igned to the case side, 1 clamped it in place. After drilling a hole to get the bit started, 1 cut the mortises with a flush-trim bit in my router. After routing each pair of mortises, 1 left the jig clamped in place, flipped the side over and used thejig as a guide to cut the corners of the mortises square with a chisel. At this point, I walked away from mortise-and-tenon territory and went to work on the curved profiles at the top front corner of each side, and the arched cutouts at the bottom. After laying out the curves on one side, I cut close to the line with ajigsaw and cleaned up the edges with a rasp. The first side was put into service as a template for the second. 1 put the finished side on top of the other and traced the curves. Craftsman Bookcase

Built around the holes. This jig for the through-mortises is made by assembling small pieces tc backer. The openings are then cut with a router and a locating fence is added. Double duty. After routing, the mortising jig also serves as a guide for the chisel to Getting in shape. After cutting the lower arch with a jigsaw, square the corners of the through-mortises. the curve is smoothed with a rasp. |