Popular Woodworking 2008-12 № 173, страница 31

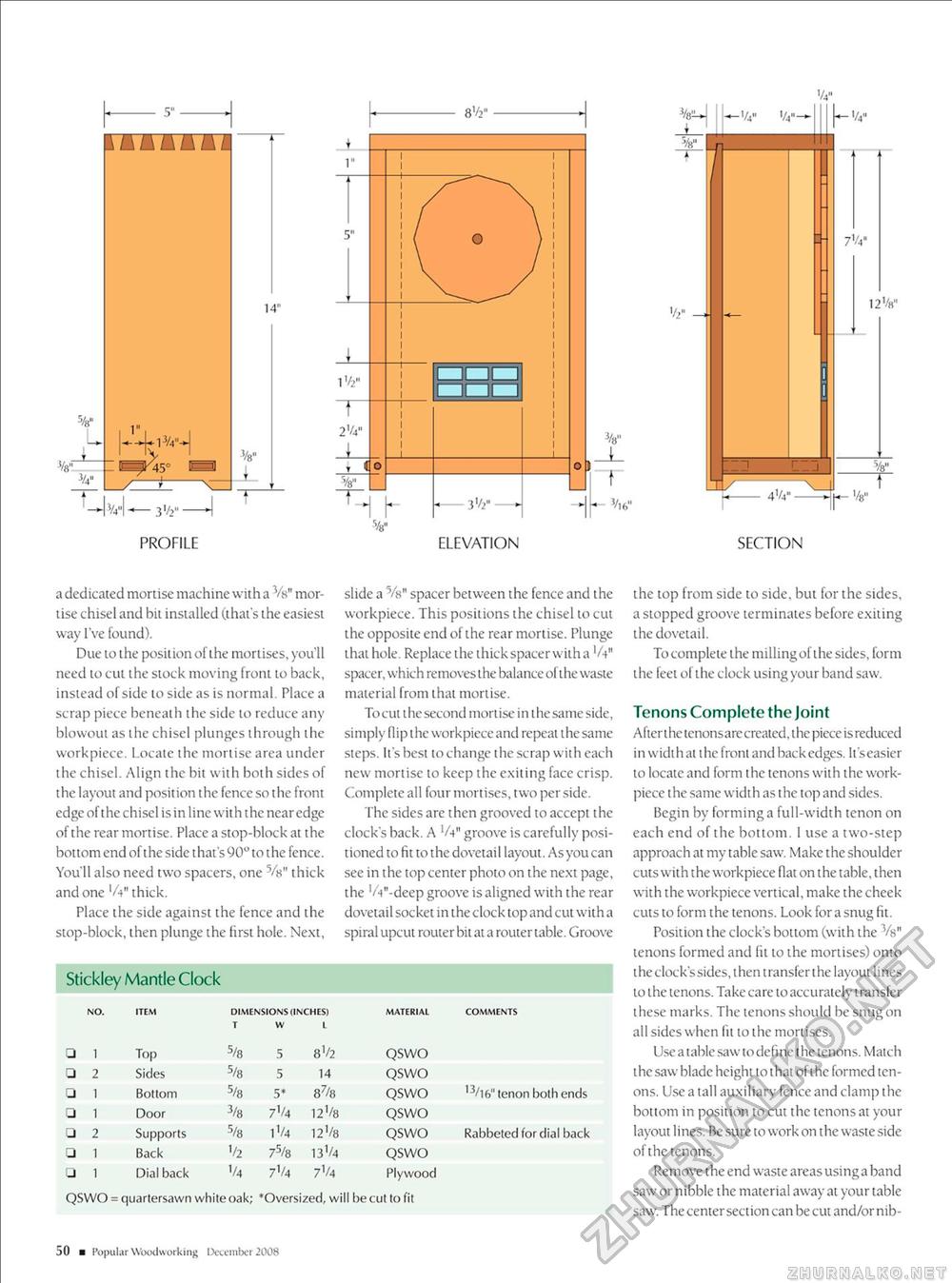

5" wwwwwwi %r 5/«" 3/4" 1" 45° ii- 14" 3/8" _L — 3'/>"- PROFILE *jp- 3/l6" *H i/4» .l/H !/,,. I—'V 3/«" 1/2» 7f B/ 4V4- 7 M 12'/H" V8" V8" ELEVATION SECTION a dedicated mortise machine with a Vs" mortise chisel and bit installed (that's the easiest way I've found). Due to the position of the mortises, you'll need to cut the stock moving front 10 back, instead of side to side as is normal. Place a scrap piece beneath the side to reduce any blowout as ihe chisel plunges through the workpiece. Locate the mortise area under the chisel. Align the bit with both sides of the layout and position the fence so the front edge of the chisel is in line with the near edge of the rear mortise. Place a stop-block at the bottom end of the side that's 90" to the fence. You'll also need two spacers, one Vh" thick and one 'A" thick. Place the side against the fence and the stop-block, then plunge the first hole. Next, slide a Vs" spacer between the fence and the workpiece. This positions ihe chisel to cut the opposite end of the rear mortise. Plunge that hole. Replace the thick spacer with a 'a" spacer, which removes the balance of the waste material from that mortise. Tocut the second mortise in the same side, simply flip the workpiece and repeat the same steps. It's best to change the scrap with each new mortise to keep the exiting face crisp. Complete all four mortises, two per side. The sides arc then grooved to accept the clock's back. A 'A" groove is carefully positioned to fit to t he dovetai I layout. As you can see in the top center photo on the next page, the 1 a"-deep groove is aligned with the rear dovetail socket in the clock top and cut with a spiral upcut rouier bit at a router table. Groove Stickley Mantle Clock □ □ □ □ □ □ □ NO. 1 2 1 1 2 1 1 DIMENSIONS (INCHES) T W L Top Sides Bottom Door Supports Back Dial back 5/8 5/8 5/8 % 5/8 V2 V4 5 5 5* 8V2 14 87/8 7V4 12'/8 lV4 12'/8 75/8 I3V4 7V4 7V4 MATERIAL QSWO QSWO QSWO QSWO QSWO QSWO Plywood COMMENTS ,3/l6" tenon both ends Rabbeted for dial back QSWO = quartersawn white oak; "Oversized, will be cut to fit the top from side to side, but for the sides, a stopped groove terminates before exiling the dovetail. Tocomplete the milling of the sides, form the feet of the clock using your band saw. Tenons Complete the Joint Afterlhe lenonsarecreated, the piece is reduced in width at the front and back edges. It'seasier to locate and form the tenons with the work-piece the same width as the top and sides. Begin by forming a full-width tenon on each end of the bottom. I use a two-step approach at my table saw. Make the shoulder cuts with the workpiece flat on the table, then with the workpiece vertical, make the cheek cuts to form the tenons. Look for a snug fit. Position the clock's bottom (with the Vs" tenons formed and lil to the mortises) onto 1 he clock's sides, then transferthe layout lines to ihe lenons. Take care to accurately transfer these marks. The tenons should be snug on all sides when lit to the mortises. Use a table saw to define the tenons. Match the saw blade height to that of the formed tenons. LJse a tall auxiliary fence and clamp the bottom in position to cut the tenons at your layout lines. Be sure to work on the waste side of the tenons. Remove t he end waste areas using a band saw or nibble t he material away at your table saw. The center section can be cut and/or nib- 50 ■ Popul ar Woodworking December 2008 |