Popular Woodworking 2009-10 № 178, страница 43

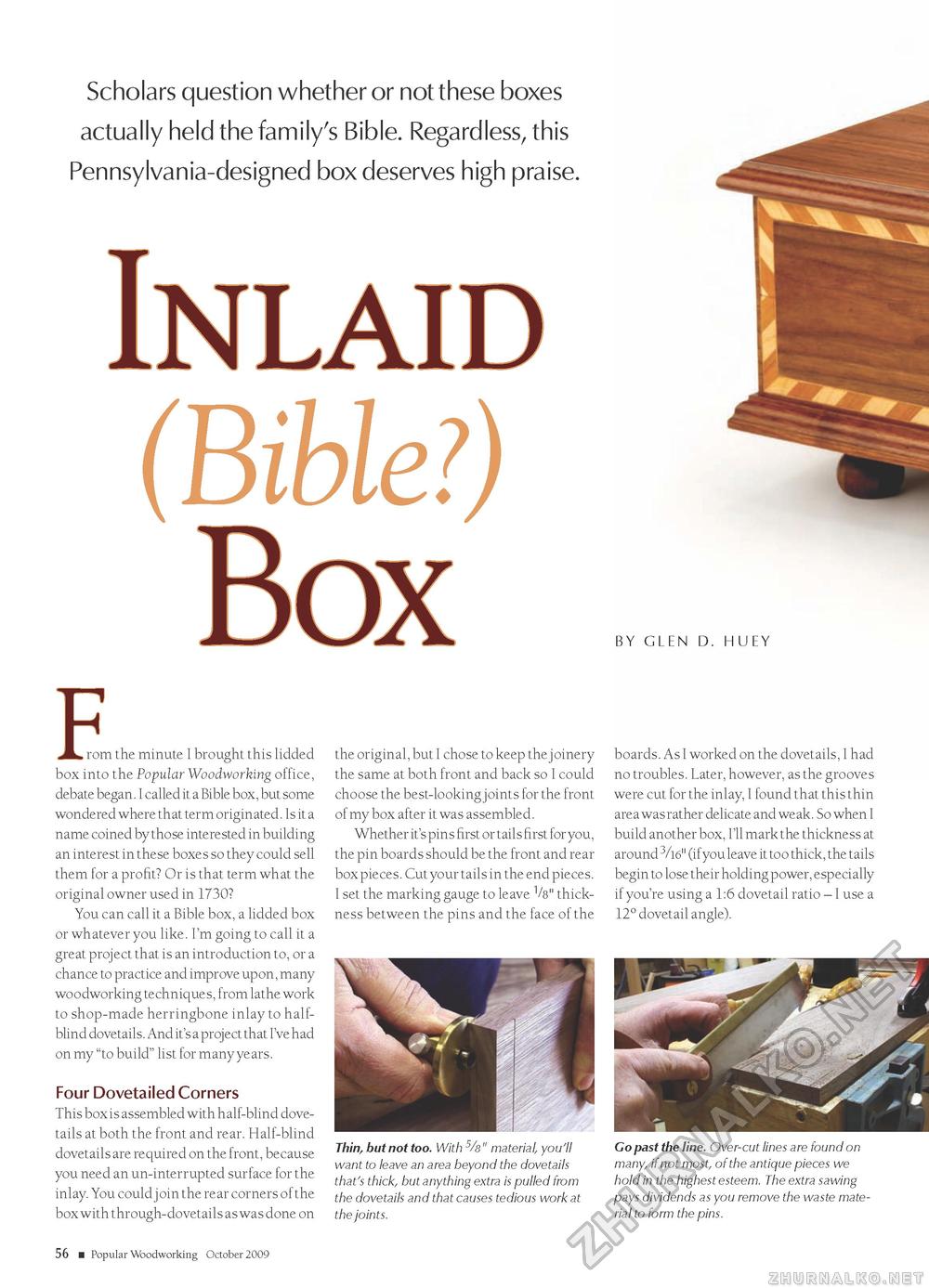

Scholars question whether or not these boxes actually held the family's Bible. Regardless, this Pennsylvania-designed box deserves high praise. Inlaid(Bible?)BoxF JL. rom the minute I brought this lidded box into the Popular Woodworking office, debate began. I called it a Bible box, but some wondered where that term originated. Is it a name coined by those interested in building an interest in these boxes so they could sell them for a profit? Or is that term what the original owner used in 1730? You can call it a Bible box, a lidded box or whatever you like. I'm going to call it a great project that is an introduction to, or a chance to practice and improve upon, many woodworking techniques, from lathe work to shop-made herringbone inlay to half-blind dovetails. And it's a project that I've had on my "to build" list for many years. Four Dovetailed Corners This box is assembled with half-blind dovetails at both the front and rear. Half-blind dovetails are required on the front, because you need an un-interrupted surface for the inlay. You could join the rear corners of the box with through-dovetails as was done on the original, but I chose to keep the joinery the same at both front and back so I could choose the best-looking joints for the front of my box after it was assembled. Whether it's pins first or tails first for you, the pin boards should be the front and rear box pieces. Cut your tails in the end pieces. I set the marking gauge to leave 1/8" thickness between the pins and the face of the Thin, but not too. With 5/b " material, you'll want to leave an area beyond the dovetails that's thick, but anything extra is pulled from the dovetails and that causes tedious work at the joints. BY GLEN D. HUEY boards. As I worked on the dovetails, I had no troubles. Later, however, as the grooves were cut for the inlay, I found that this thin area was rather delicate and weak. So when I build another box, I'll mark the thickness at around 3/16" (ifyou leave it too thick, the tails begin to lose their holding power, especially if you're using a 1:6 dovetail ratio - I use a 12° dovetail angle). Go past the line. Over-cut lines are found on many, if not most, of the antique pieces we hold in the highest esteem. The extra sawing pays dividends as you remove the waste material to form the pins. 56 ■ Popular Woodworking October 2009 |