Popular Woodworking 2009-12 № 180, страница 47

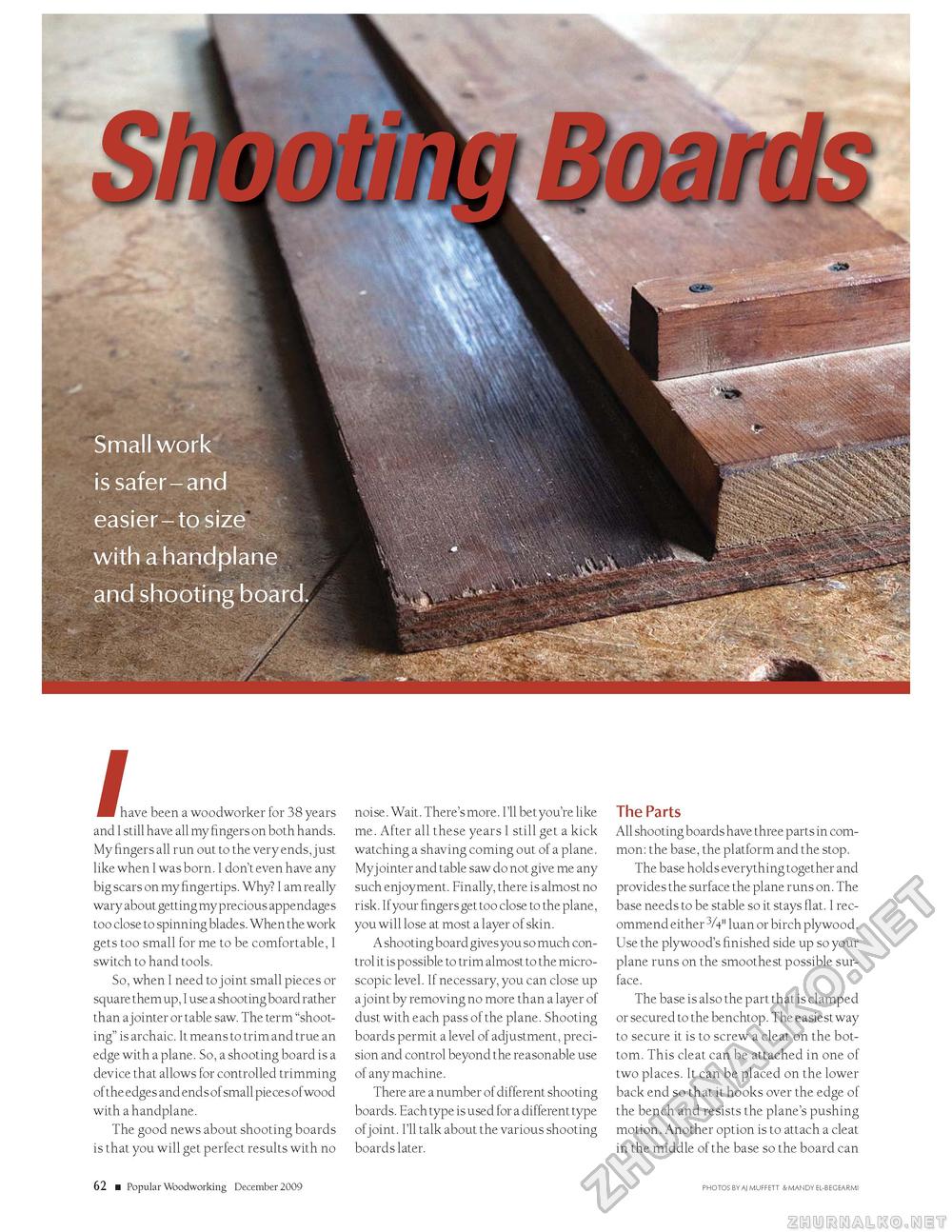

have been a woodworker for 38 years and I still have all my fingers on both hands. My fingers all run out to the very ends, just like when I was born. I don't even have any big scars on my fingertips. Why? I am really wary about getting my precious appendages too close to spinning blades. When the work gets too small for me to be comfortable, I switch to hand tools. So, when I need to joint small pieces or square them up, I use a shooting board rather than a jointer or table saw. The term "shooting" is archaic. It means to trim and true an edge with a plane. So, a shooting board is a device that allows for controlled trimming of the edges and ends of small pieces ofwood with a handplane. The good news about shooting boards is that you will get perfect results with no noise. Wait. There's more. I'll bet you're like me. After all these years I still get a kick watching a shaving coming out of a plane. Myj ointer and table saw do not give me any such enj oyment. Finally, there is almost no risk. If your fingers get too close to the plane, you will lose at most a layer of skin. A shooting board gives you so much control it is possible to trim almost to the microscopic level. If necessary, you can close up a joint by removing no more than a layer of dust with each pass of the plane. Shooting boards permit a level of adjustment, precision and control beyond the reasonable use of any machine. There are a number of different shooting boards. Each type is used for a different type of joint. I'll talk about the various shooting boards later. The PartsAll shooting boards have three parts in common: the base, the platform and the stop. The base holds everything together and provides the surface the plane runs on. The base needs to be stable so it stays flat. I recommend either 3A" luan or birch plywood. Use the plywood's finished side up so your plane runs on the smoothest possible surface. The base is also the part that is clamped or secured to the benchtop. The easiest way to secure it is to screw a cleat on the bottom. This cleat can be attached in one of two places. It can be placed on the lower back end so that it hooks over the edge of the bench and resists the plane's pushing motion. Another option is to attach a cleat in the middle of the base so the board can 62 ■ Popular Woodworking December 2009 PHOTOS BY A) MUFFETT & MANDY EL-BEGEARM |