15 - Sliding Table, страница 9

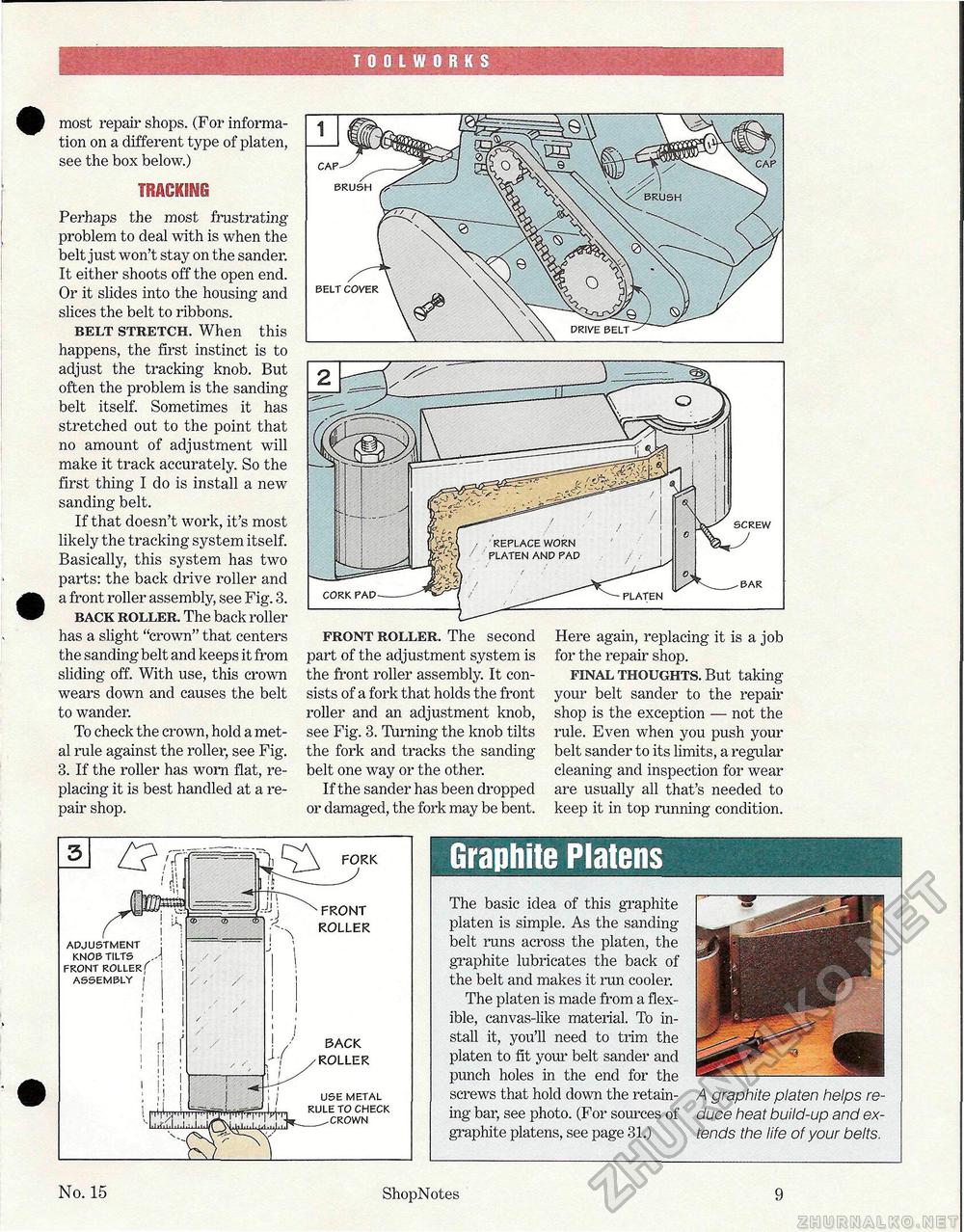

TOOLWORKS most repair shops. (For information on a different type of platen, see the box below.) TRACKING Perhaps the most frustrating problem to deal with is when the belt just won't stay on the sander. It either shoots off the open end. Or it slides into the housing and slices the belt to ribbons. belt stretch. When this happens, the first instinct is to adjust the tracking knob. But often the problem is the sanding belt itself. Sometimes it has stretched out to the point that no amount of adjustment will make it track accurately. So the first thing I do is install a new sanding belt. If that doesn't work, it's most likely the tracking system itself. Basically, this system has two parts: the back drive roller and a front roller assembly, see Fig. 3. back roller. The back roller has a slight "crown" that centers the sanding belt and keeps it from sliding off. With use, this crown wears down and causes the belt to wander. To check the crown, hold a metal rule against the roller, see Fig. 3. If the roller has worn flat, replacing it is best handled at a repair shop. front roller. The second part of the adjustment system is the front roller assembly. It consists of a fork that holds the front roller and an adjustment knob, see Fig. 3. Turning the knob tilts the fork and tracks the sanding belt one way or the other. If the sander has been dropped or damaged, the fork may be bent. Here again, replacing it is a job for the repair shop. final thoughts. But taking your belt sander to the repair shop is the exception — not the rule. Even when you push your belt sander to its limits, a regular cleaning and inspection for wear are usually all that's needed to keep it in top running condition. ■nm mm* a r?l?!li —_------H The basic idea of this graphite platen is simple. As the sanding belt runs across the platen, the graphite lubricates the back of the belt and makes it run cooler. The platen is made from a flexible, canvas-like material. To install it, you'll need to trim the platen to fit your belt sander and punch holes in the end for the screws that hold down the retaining bar, see photo. (For sources of graphite platens, see page 31.)

/A graphite platen helps reduce heat build-up and extends the life of your belts. No. 15 ShopNotes 9 |

|||||||||||||||