19 - Clamp Storage System, страница 21

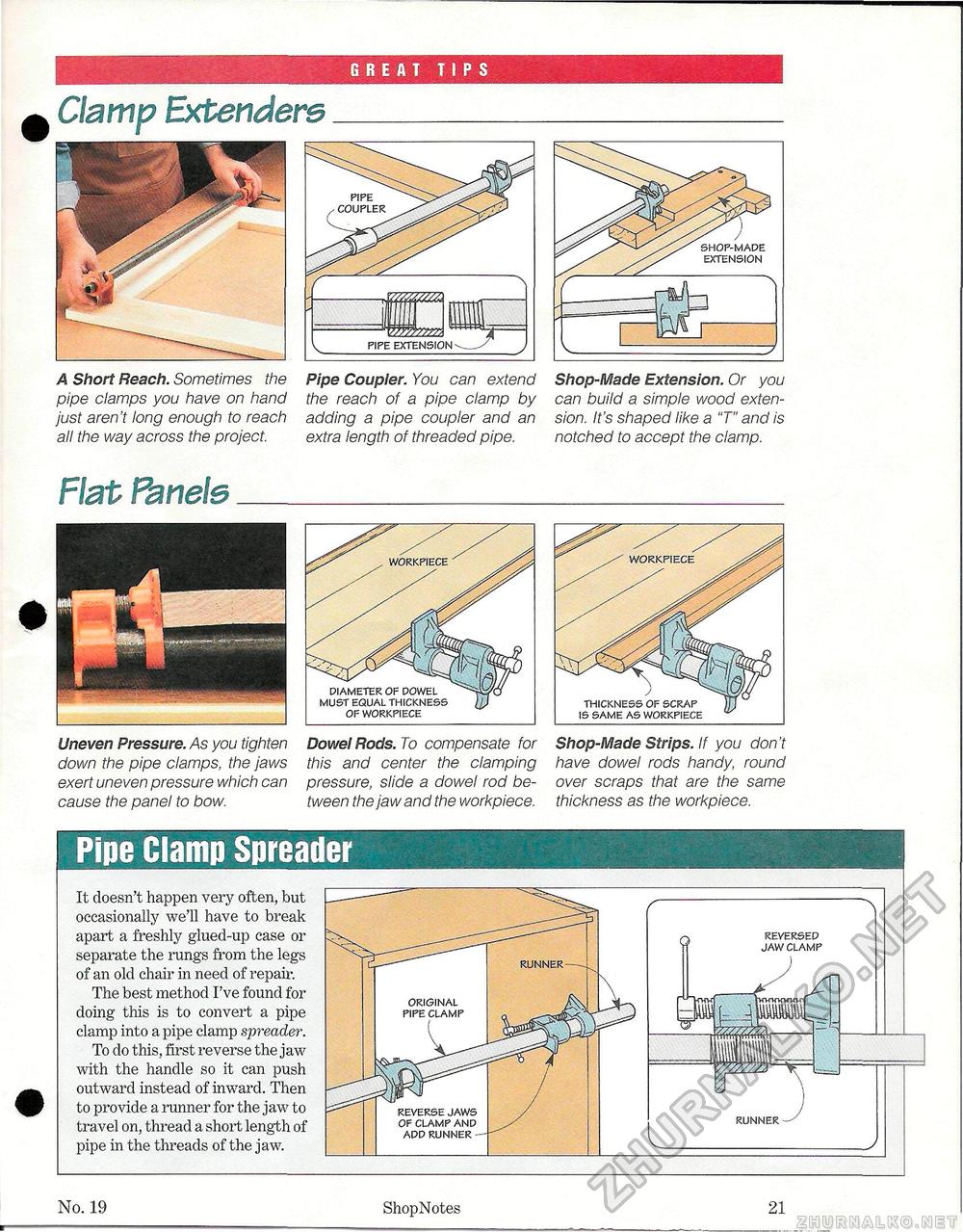

GREAT TIPS A Short Reach. Sometimes the pipe clamps you have on hand just aren't long enough to reach all the way across the project. Pipe Coupler. You can extend the reach of a pipe clamp by adding a pipe coupler and an extra length of threaded pipe. Shop-Made Extension. Or you can build a simple wood extension. It's shaped like a "T" and is notched to accept the clamp. Fiat Panels 0 Uneven Pressure. As you tighten down the pipe clamps, the jaws exert uneven pressure which can cause the panel to bow. Dowel Rods. To compensate for this and center the clamping pressure, slide a dowel rod between the jaw and the workpiece. Shop-Made Strips. If you don't have dowel rods handy, round over scraps that are the same thickness as the workpiece. Clamp Extenders SHOP-MADE EXTENSION PIPE EXTENSION WORKPIECE DIAMETER OF DOWEL MUST EQUAL THICKNESS OF WORKPIECE Pipe Clamp Spreader It doesn't happen very often, but occasionally we'll have to break apart a freshly glued-up case or separate the rungs from the legs of an old chair in need of repair. The best method I've found for doing this is to convert a pipe clamp into a pipe clamp spreader. To do this, first reverse the jaw with the handle so it can push outward instead of inward. Then to provide a runner for the jaw to travel on, thread a short length of pipe in the threads of the jaw. ORIGINAL PIPE CLAMP REVERSED JAW CLAMP RUNNER No. 19 ■ ShopNotes |