36 - Miter Trimmer, страница 19

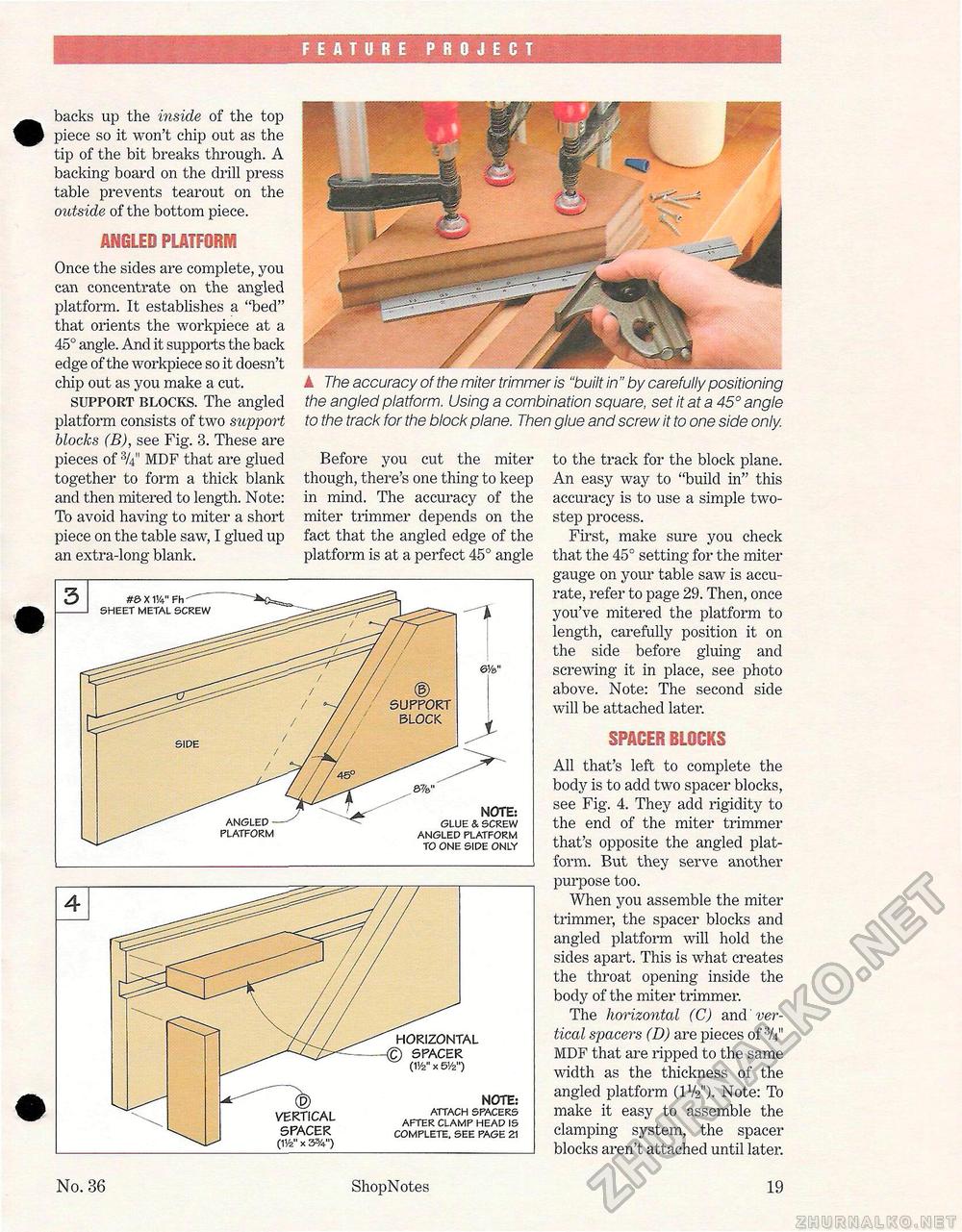

FEATURE PROJECT Hi hHHRRmHI backs up the insicle of the top piece so it won't chip out as the tip of the bit breaks through. A backing board on the drill press table prevents tearout on the outside of the bottom piece. ANGLED PLATFORM spacer blocks All that's left to complete the body is to add two spacer blocks, see Fig. 4. They add rigidity to the end of the miter trimmer that's opposite the angled platform. But they serve another purpose too. When you assemble the miter trimmer, the spacer blocks and angled platform will hold the sides apart. This is what creates the throat opening inside the body of the miter trimmer. The horizontal (C) and vertical spacers (D) are pieces of3// MDF that are ripped to the same width as the thickness of the angled platform (IV2"). Note: To make it easy to assemble the clamping system, the spacer blocks aren't attached until later. Once the sides are complete, you can concentrate on the angled platform. It establishes a "bed" that orients the workpiece 45° angle. And it supports the back edge of the workpiece so it doesn't chip out as you make a cut. support blocks. The angled platform consists of two support blocks (B), see Fig. 3. These are pieces of 34" MDF that are glued together to form a thick blank and then mitered to length. Note: To avoid having to miter a short piece on the table saw, I glued up an extra-long blank. #& X VA" Fh SHEET METAL SCREW SIDE PLATFORM NOTE: GLUE & SCREW ANGLED PLATFORM TO ONE SIDE ONLY A The accuracy of the miter trimmer is "built in" by carefully positioning the angled platform. Using a combination square, set it at a 45° angle to the track for the block plane. Then glue and screw it to one side only. Before you cut the miter though, there's one thing to keep in mind. The accuracy of the miter trimmer depends on the fact that the angled edge of the platform is at a perfect 45° angle to the track for the block plane. An easy way to "build in" this accuracy is to use a simple two-step process. First, make sure you check that the 45° setting for the miter gauge on your table saw is accurate, refer to page 29. Then, once you've mitered the platform to length, carefully position it on the side before gluing and screwing it in place, see photo above. Note: The second side will be attached later. © VERTICAL SPACER (11/z" x 3%") HORIZONTAL SPACER (11/2" x 5Vz") NOTE: ATTACH SPACERS AFTER CLAMP HEAD IS COMPLETE, SEE PAGE 21 No. 36 ShopNotes 19 |