41 - Fold-Down Drafting Table, страница 30

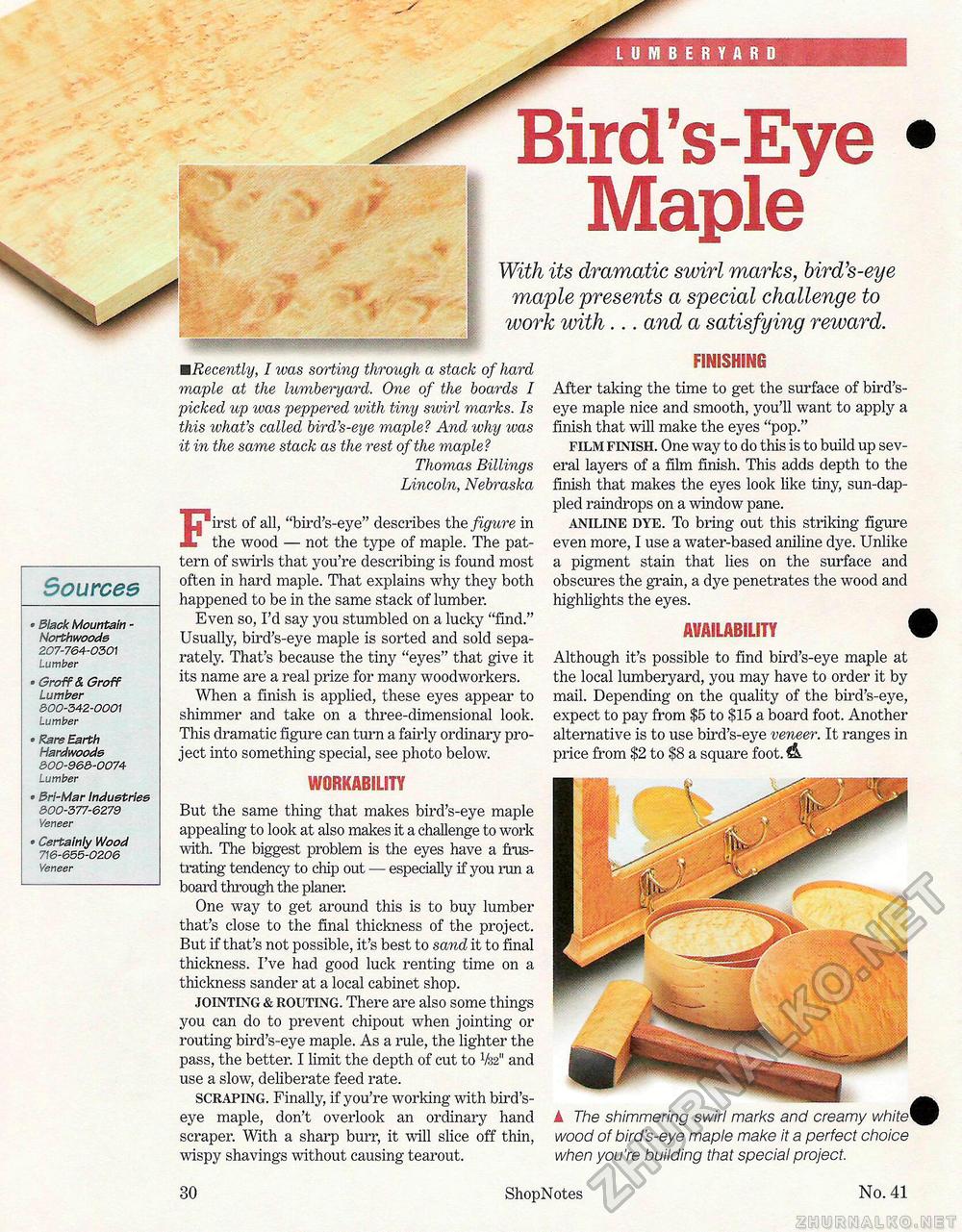

Sources • 5!ack Mountain -Northwoods 207-764-0301 lumber • Groff& Groff Lumber 300-342-0001 Lumber • Rare Earth Hardwoods 300-963-0074 Lumber • Bri-Mar Industries 300-377-6279 Veneer • Certainly Wood 716-655-0206 Veneer lUMBERYARD V/ M s-Sye Maple With its dramatic swirl marks, bird's-eye maple presents a special challenge to work with... and a satisfying reward. URecently, I ivas sorting through a stack of hard maple at the lumberyard. One of the boards I picked up ivas peppered with tiny sivirl marks. Is this what's called bird's-eye maple? And why was it in the same stack as the rest of the maple? Thomas Billings Lincoln, Nebraska First of all, "bird's-eye" describes the figure in the wood — not the type of maple. The pattern of swirls that you're describing is found most often in hard maple. That explains why they both happened to be in the same stack of lumber. Even so, I'd say you stumbled on a lucky "find." Usually, bird's-eye maple is sorted and sold separately. That's because the tiny "eyes" that give it its name are a real prize for many woodworkers. When a finish is applied, these eyes appear to shimmer and take on a three-dimensional look. This dramatic figure can turn a fairly ordinary project into something special, see photo below. WORKABILITY But the same thing that makes bird's-eye maple appealing to look at also makes it a challenge to work with. The biggest problem is the eyes have a frustrating tendency to chip out — especially if you run a board through the planer. One way to get around this is to buy lumber that's close to the final thickness of the project. But if that's not possible, it's best to sand it to final thickness. I've had good luck renting time on a thickness sander at a local cabinet shop. jointing & routing. There are also some things you can do to prevent chipout when jointing or routing bird's-eye maple. As a rule, the lighter the pass, the better. I limit the depth of cut to V32" and use a slow, deliberate feed rate. scraping. Finally, if you're working with bird's-eye maple, don't overlook an ordinary hand scraper. With a sharp burr, it will slice off thin, wispy shavings without causing tearout. FINISHING After taking the time to get the surface of bird's-eye maple nice and smooth, you'll want to apply a finish that will make the eyes "pop." film finish. One way to do this is to build up several layers of a film finish. This adds depth to the finish that makes the eyes look like tiny, sun-dappled raindrops on a window pane. aniline dye. To bring out this striking figure even more, I use a water-based aniline dye. Unlike a pigment stain that lies on the surface and obscures the grain, a dye penetrates the wood and highlights the eyes. AVAILABILITY Although it's possible to find bird's-eye maple at the local lumberyard, you may have to order it by mail. Depending on the quality of the bird's-eye, expect to pay from $5 to $15 a board foot. Another alternative is to use bird's-eye veneer. It ranges in price from $2 to $8 a square foot. ^ A The shimmering swirl marks and creamy white* wood of bird's-eye maple make it a perfect choice when you're building that special project. 30 ShopNotes No. 41 |