44 - Grinding Station, страница 21

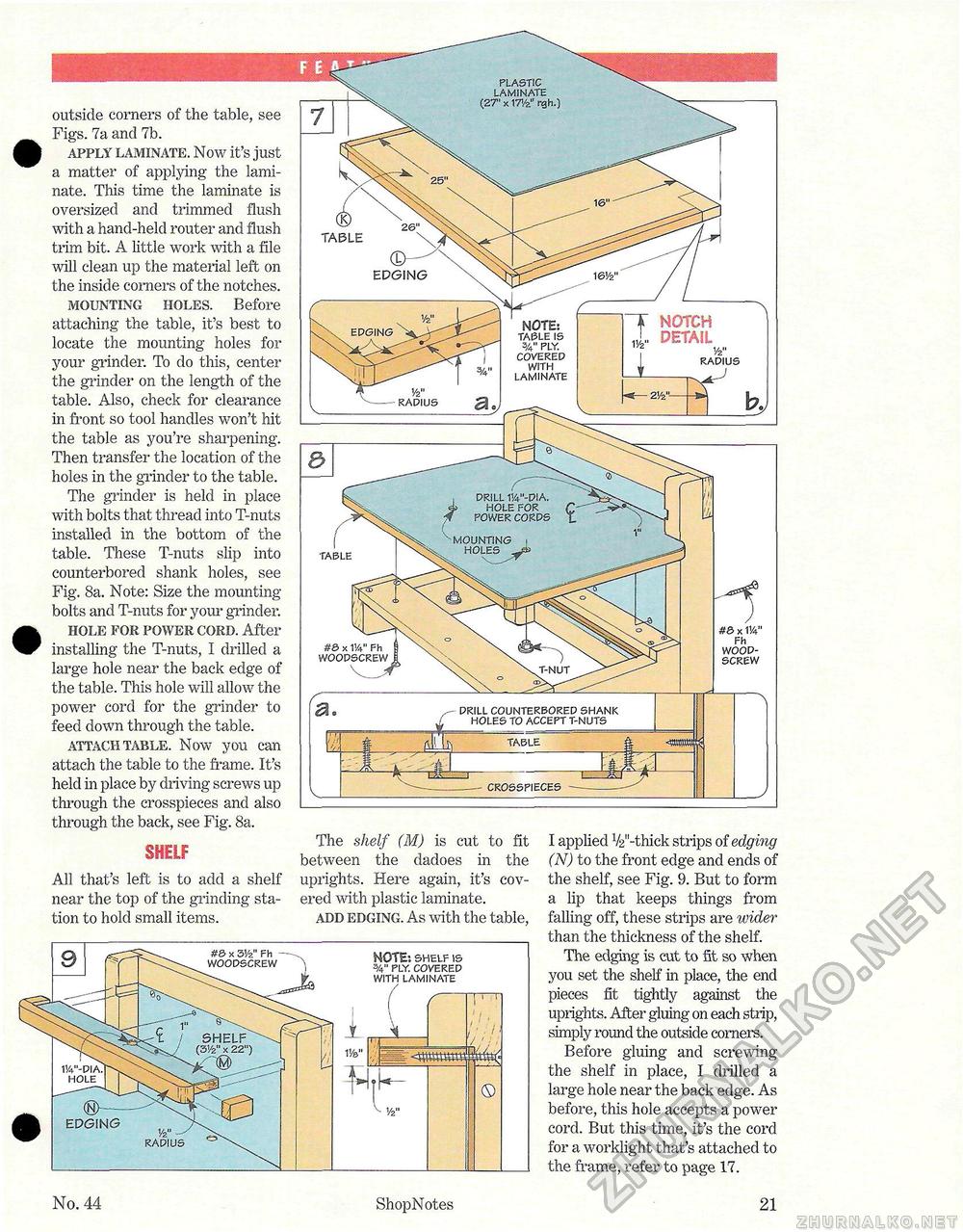

outside corners of the table, see Figs. 7a and 7b. apply laminate. Now it's just a matter of applying the laminate. This time the laminate is oversized and trimmed flush with a hand-held router and flush trim bit. A little work with a file will clean up the material left on the inside corners of the notches. mounting holes. Before attaching the table, it's best to locate the mounting holes for your grinder. To do this, center the grinder on the length of the table. Also, check for clearance in front so tool handles won't hit the table as you're sharpening. Then transfer the location of the holes in the grinder to the table. The grinder is held in place with bolts that thread into T-nuts installed in the bottom of the table. These T-nuts slip into counterbored shank holes, see Fig. 8a. Note: Size the mounting-bolts and T-nuts for your grinder. hole for power cord. After installing the T-nuts, I drilled a large hole near the back edge of the table. This hole will allow the power cord for the grinder to feed down through the table. attach table. Now you can attach the table to the frame. It's held in place by driving screws up through the crosspieces and also through the back, see Fig. 8a. SHELF All that's left is to add a shelf near the top of the grinding station to hold small items. The shelf (M) is cut to fit between the dadoes in the uprights. Here again, it's covered with plastic laminate. add edging. As with the table, MOTE'. SHELF IS W PLY. COVERED WITH LAMINATE V/e" T< A v y2" i r I ■ IJ- © I applied V2"-thick strips of edging (N) to the front edge and ends of the shelf, see Fig. 9. But to form a lip that keeps things from falling off, these strips are wider than the thickness of the shelf. The edging is cut to fit so when you set the shelf in place, the end pieces fit tightly against the uprights. After gluing on each strip, simply round the outside corners. Before gluing and screwing the shelf in place, I drilled a large hole near the back edge. As before, this hole accepts a power cord. But this time, it's the cord for a worklight that's attached to the frame, refer to page 17. 3/4" 1/2" ^ RADIUS 0 PLASTIC LAMINATE Vz" RADIUS #& x 114" Fh WOOD-SCREW I DRILL COUNTERBORED SHANK HOLES TO ACCEPT T-NUTS TABLE CROSSPIECES TABLE EDGING TABLE #& x IV4" Fh WOODSCREW TABLE IS 3/4" PLY. COVERED WITH LAMINATE EDGING RADIUS No. 44 ShopNotes 21 |