49 - Cabinet Maker's Tool Chest, страница 24

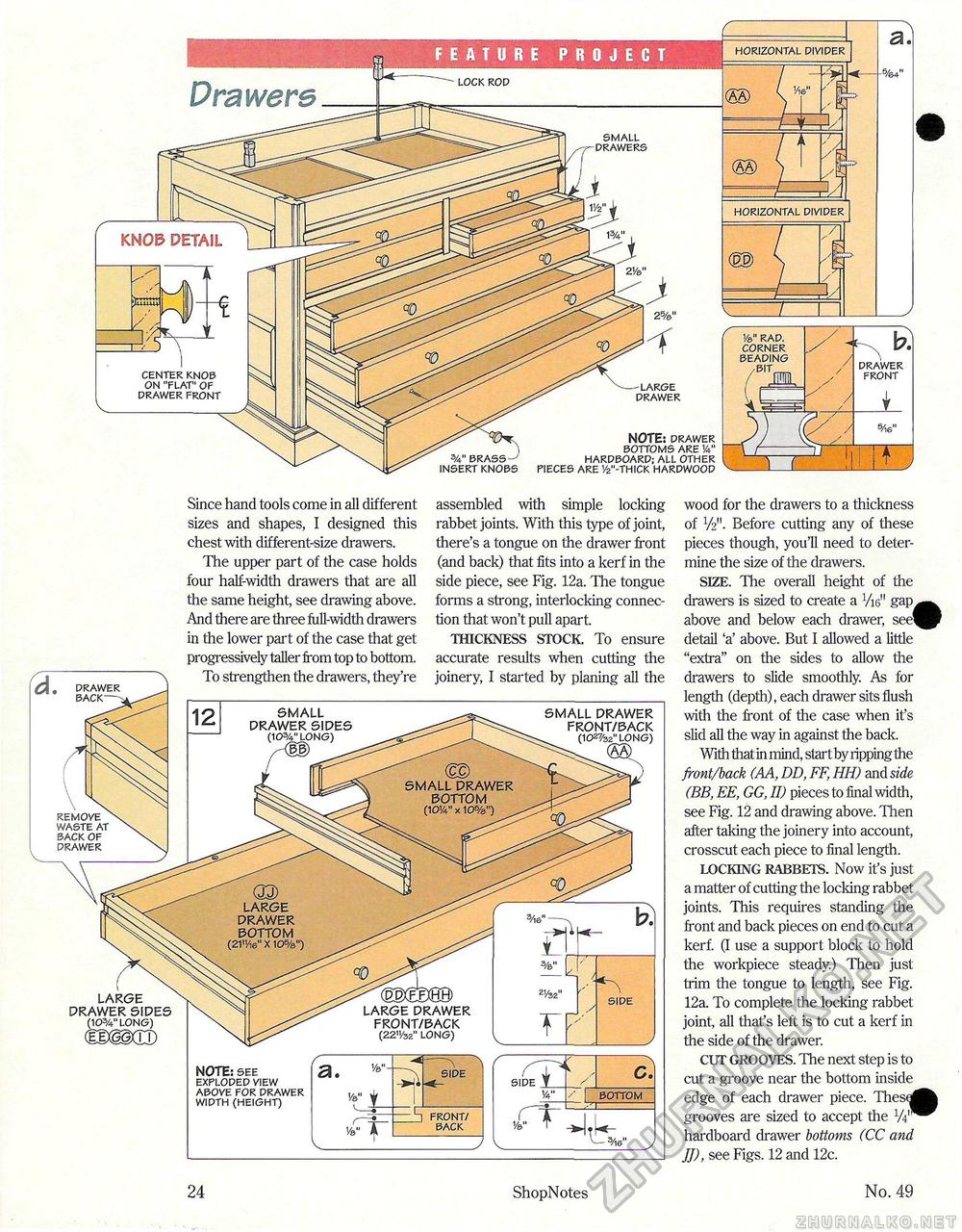

FEATURE PROJECT Drawers 3A" BRASS INSERT KNOBS — LARGE DRAWER NOTE: DRAWER BOTTOMS ARE 14" HARDBOARD; ALL OTHER PIECES ARE 1/2"-TH!CK HARDWOOD Since hand tools come in all different sizes and shapes, I designed this chest with different-size drawers. The upper part of the case holds four half-width drawers that are all the same height, see drawing above. And there are three full-width drawers in the lower part of the case that get progressively taller from top to bottom. To strengthen the drawers, they're assembled with simple locking rabbet joints. With this type of joint, there's a tongue on the drawer front (and back) that fits into a kerf in the side piece, see Fig. 12a. The tongue forms a strong, interlocking connection that won't pull apart. THICKNESS STOCK. To ensure accurate results when cutting the joinery, I started by planing all the wood for the drawers to a thickness of V2". Before cutting any of these pieces though, you'll need to determine the size of the drawers. SIZE. The overall height of the drawers is sized to create a Vie" gap above and below each drawer, see! detail 'a' above. But I allowed a little "extra" on the sides to allow the drawers to slide smoothly. As for length (depth), each drawer sits flush with the front of the case when it's slid all the way in against the back. With that in mind, start by rippingthe front/back (AA, DD, FF, HH) and side (BB, EE, GG, II) pieces to final width, see Fig. 12 and drawing above. Then after taking the joinery into account, crosscut each piece to final length. LOCKING RABBET'S. Now it's just a matter of cutting the locking rabbet joints. This requires standing the front and back pieces on end to cut a kerf. (I use a support block to hold the workpiece steady.) Then just trim the tongue to length, see Fig. 12a. To complete the locking rabbet joint, all that's left is to cut a kerf in the side of the drawer. CUT GROOVES. The next step is to cut a groove near the bottom inside edge of each drawer piece. Thesd^ grooves are sized to accept the W^^ hardboard drawer bottoms (CC and JJ), see Figs. 12 and 12c. 24 ShopNotes No. 49 |