50 - Table Saw Workstation, страница 28

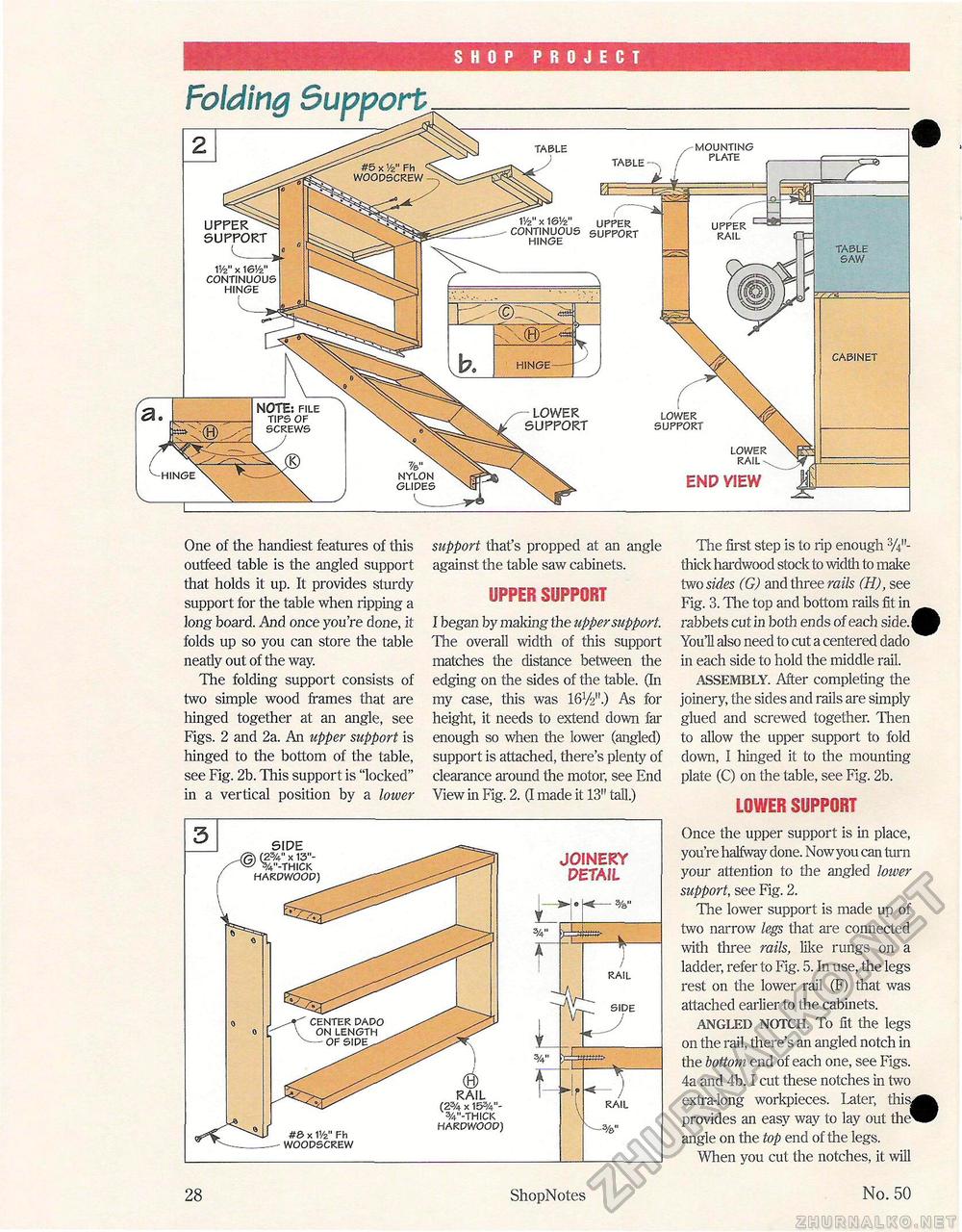

SHOP PROJECT Folding 5upportmounting plate table table #5x1/z"Fh woodscrew V/z x 1s/2 upper continuous support hinge UPPERS SUPPORT upper rail table saw 1'/z" x 16Vz" continuous hinge cabinet hinge NOTE: file tips of screws - LOWER SUPPORT lower support lower rail v. nylon glides hinge END VIEW One of the handiest features of this outfeed table is the angled support that holds it up. It provides sturdy support for the table when ripping a long board. And once you're done, it folds up so you can store the table neatly out of the way. The folding support consists of two simple wood frames that are hinged together at an angle, see Figs. 2 and 2a. An upper support is hinged to the bottom of the table, see Fig. 2b. This support is "locked" in a vertical position by a lower support that's propped at an angle against the table saw cabinets. UPPER SUPPORT I began by making the upper support. The overall width of this support matches the distance between the edging on the sides of the table. (In my case, this was I6V2".) As for height, it needs to extend down far enough so when the lower (angled) support is attached, there's plenty of clearance around the motor, see End View in Fig. 2. (I made it 13" tall.) The first step is to rip enough 3A"-thick hardwood stock to width to make two sides (G) and three rails (H), see Fig. 3. Hie top and bottom rails fit in rabbets cut in both ends of each side.j YouH also need to cut a centered dado in each side to hold the middle rail. ASSEMBLY. After completing the joinery, the sides and rails are simply glued and screwed together. Then to allow the upper support to fold down, I hinged it to the mounting plate (C) on the table, see Fig. 2b. LOWER SUPPORT Once the upper support is in place, you're halfway done. Now you can turn your attention to the angled lower support, see Fig. 2. The lower support is made up of two narrow legs that are connected with three rails, like rungs on a ladder, refer to Fig. 5. In use, the legs rest on the lower rail (F) that was attached earlier to the cabinets. ANGLED NOTCH. To fit the legs on the rail, there's an angled notch in the bottom end of each one, see Figs. 4a and 4b. I cut these notches in two extra-long workpieces. I^ater, this, provides an easy way to lay out the" angle on the top end of the legs. When you cut the notches, it will 28 ShopNotes No. 50 |